Automatic plugging-in device of connector pin

An automatic insertion and connector technology, applied in the assembly/disassembly of contacts, can solve the problems of non-adjustment, high noise, time-consuming and labor-intensive, etc., and achieve the effect of convenient feeding and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

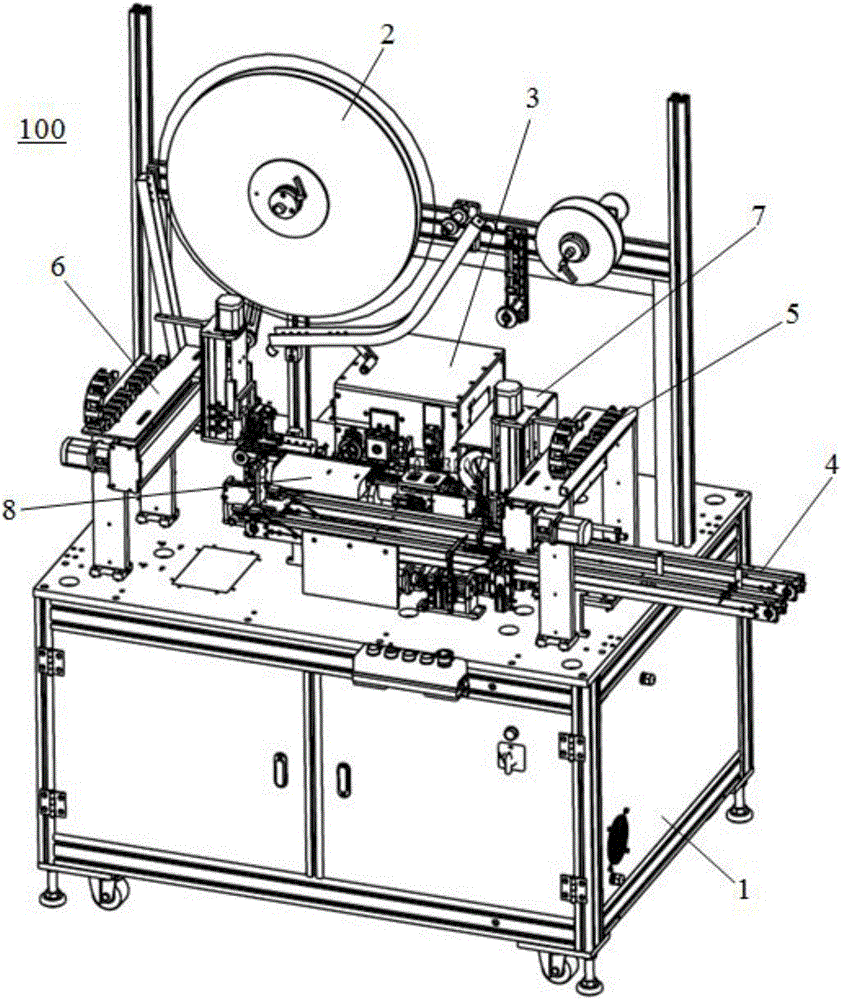

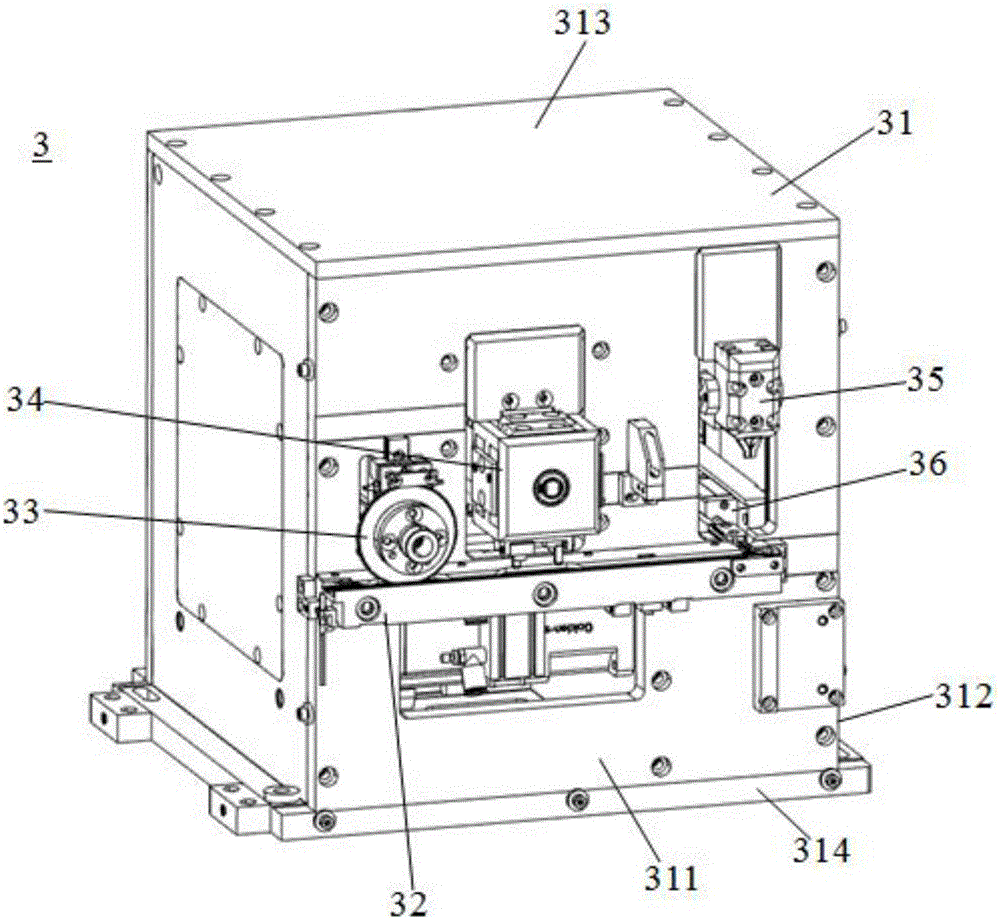

[0054] Please refer to Figure 1-Figure 19 , the present embodiment is an automatic insertion device 100 for connector pins, which includes a frame 1, a feeding device 2 fixed on the frame 1 for storing pin coils, and a plugging device 2 docked with the feeding device 2. Device 3, the terminal conveying device 4 arranged in front of the plug-in device 3, the feeding device 5 and the unloading device 6 arranged at both ends of the terminal conveying device 4, the CCD camera device 7 arranged on the side of the plug-in device 3, and the The terminal receiving device 8 between the plug-in device 3 and the terminal conveying device 4 .

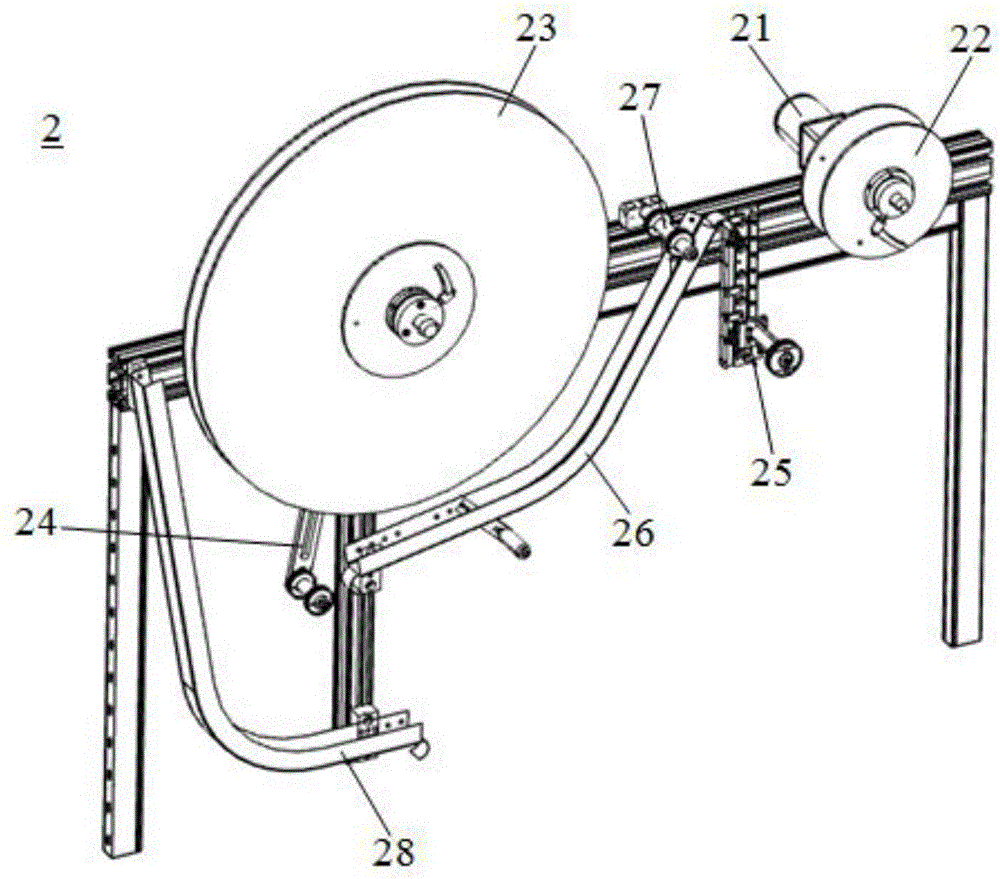

[0055] The discharge device 2 includes a first driving device 21 fixed on the frame 1 to provide power for the transmission of the material belt, a driving wheel 22 fixed on the rotating end of the first driving device 21, a discharging roller 23 for storing and discharging the material belt, The first tensioning device 24 on the edge of the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com