Small variable-capacity plastic electric-heating greenhouse in greenhouse

A technology of plastic greenhouses and electric heating sheds, applied in climate change adaptation, greenhouse cultivation, gardening, etc., can solve the problem of heating waste in idle spaces, and achieve the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

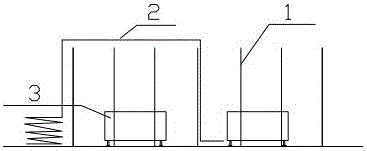

[0011] A variable-capacity plastic greenhouse electric heating shed, including a shed film 2 and a series of bow frames 1 standing in parallel, and 1 to a plurality of electric heaters 3, the shed film is dynamically draped in different positions according to the number of crop seedlings under the bow A number of bow frames cover different areas of the ground. When there are many seedlings, they are covered more, and when there are few seedlings, they are covered less. The electric heater is located on the longitudinal axis of the shed in the shed. The canopy film on the bow shed is extended after touching the ground on both sides and draped across the ground. The unused part of the shed film is stacked under the last covered bow frame and covered with opaque objects to reduce sunlight and delay aging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com