a sub-frame

A subframe and frame technology, applied in the subframe field of independent suspension, can solve the problems of weakening the deflection of the vehicle body, and achieve the effects of expanding market share, reducing labor intensity, and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

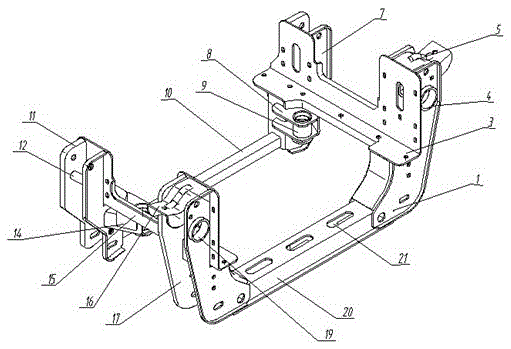

[0022] In order to make the technical means, creative features, goals and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

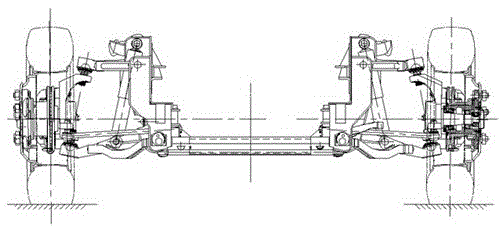

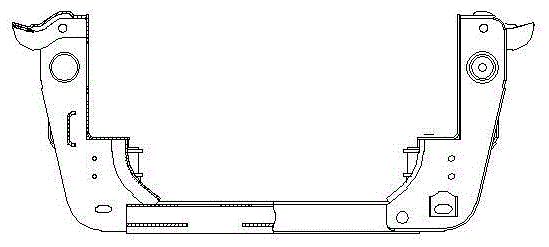

[0023] Such as figure 1 and figure 2 As shown, the auxiliary frame of the present embodiment is directly fixed on the vehicle frame by bolts, so that the vehicle axle and suspension are connected with the vehicle frame through it. The sub-frame main body is a welded frame structure, including L-shaped left / right beams 15,3 facing inwardly and left / right front brackets 11,7 and left / right rear brackets 17,1 welded thereon respectively. The whole of the subframe assembly is symmetrical with respect to the middle plane of the elevation of the left / right beam.

[0024] The left / right side beams 15, 3, the main body is L-shaped, stamped from steel plates, including horizontal plates and vertical plates with an included angle of 90 degrees. There are two sets of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com