Dedusting device of textile machine

A dust removal device and textile machine technology, applied in the direction of dust removal, deodorization, transportation and packaging, etc., can solve the problems such as unsatisfactory dust removal effect, achieve the effect of convenient replacement, improve dust removal efficiency, and purify the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

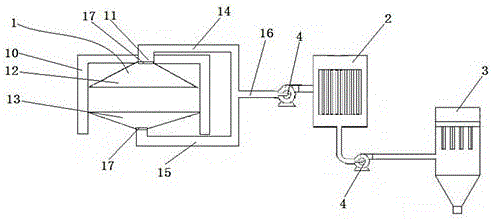

[0021] see figure 1 , figure 1 The textile machine dedusting device of the present invention comprises:

[0022] A dust collection device 1: including: a bracket 10, which is a right-angled concave structure with an opening downward, and is arranged on the working table of the textile machine. A through hole 11 is provided in the center of the top of the bracket 10, and a Inverted tapered upper dust suction port 12, a tapered lower dust suction port 13 is installed at the bottom of the bracket 10, the upper dust suction port 12 is connected with an upper dust suction pipe 14 that runs through the through hole 11, the lower suction port The dust inlet 13 is connected with a lower dust suction pipe 15, the upper dust suction pipe 14 and the lower dust suction pipe 15 merge into the main dust suction pipe 16, the top of the upper dust suction port 12 and the bottom of the lower dust suction port 13 can be disassembled Ground is provided with activated carbon deodorization layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com