Manipulator component for universal robot

A manipulator component and robot technology, applied in the field of robotics, can solve the problems of workpiece falling off, grasping the workpiece, and keeping the movement range of multiple claws consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

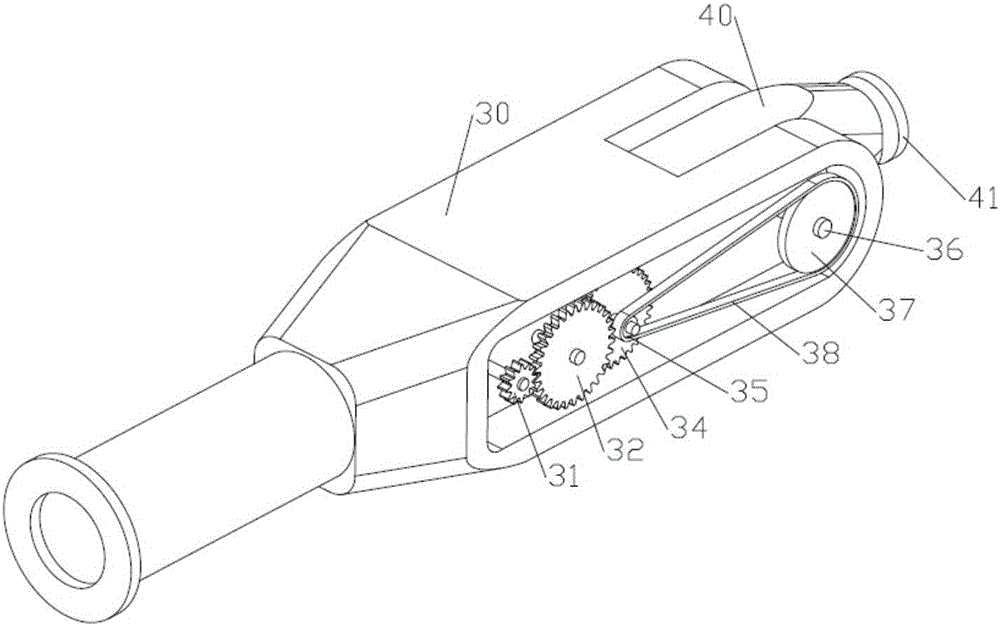

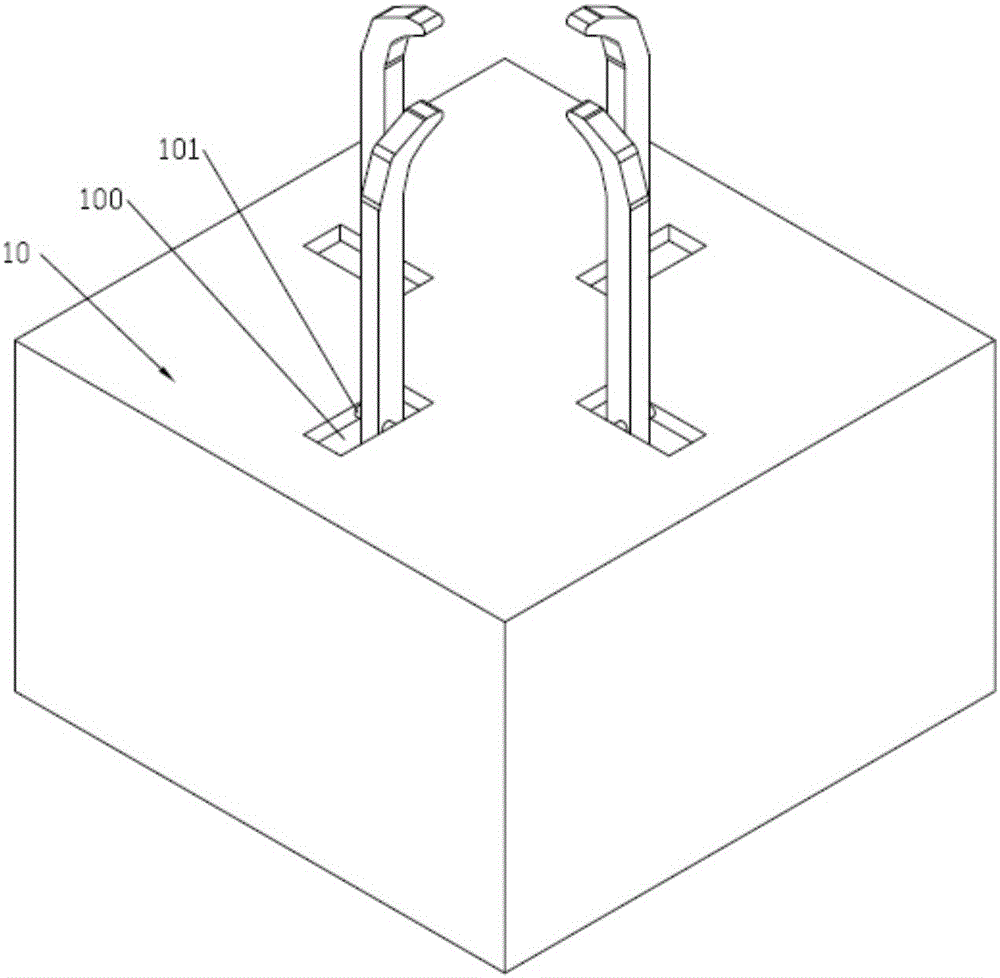

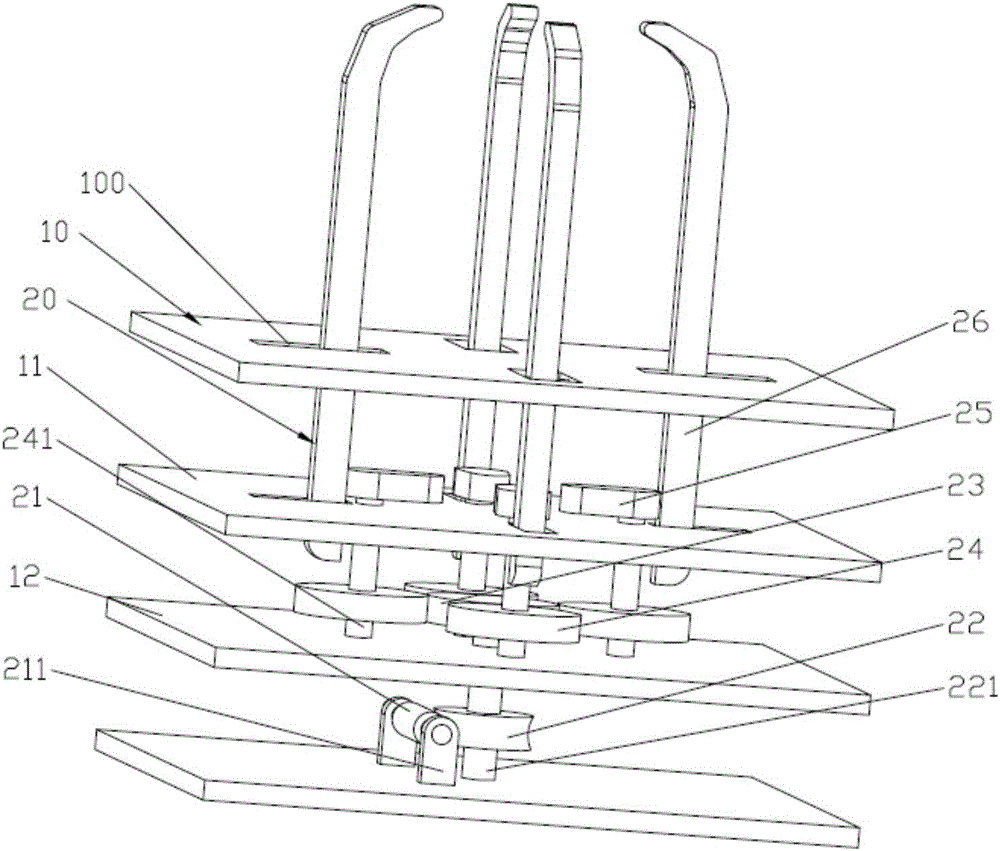

[0023] Such as Figure 1 to Figure 8 As shown, a manipulator assembly of a general robot includes an arm 30, a swing arm 40 pivotally connected to the front end of the arm 30, a first drive unit for driving the swing arm 40 to swing, a manipulator fixed on the rotating disc 41 at the front end of the swing arm 40, and The second drive unit that drives the rotating disk 41 to rotate; the centerline of the swing arm 40 when swinging is perpendicular to the rotation centerline of the rotating disk 41; the manipulator includes a housing 10 and a gripper drive mechanism 20; Drive motor 27, worm screw 21, worm wheel 22, central gear 23, some sub-gears 24, some cams 25 and some grippers 26;

[0024] Such as Figure 1 to Figure 8 As shown, the housing 10 is a cuboid with a cavity inside; the gripper driving mechanism 20 is arranged in the inner cavity of the housing 10; the center of the housing 10 is formed with a first support plate 11 and a second support plate arranged horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com