Nail jetting machine capable of bending and steering

A technology of bending and shooting nails, applied in nailing tools, nailing staple tools, manufacturing tools, etc., can solve problems such as inability to automatically turn operation, and achieve the effect of enhancing practicability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

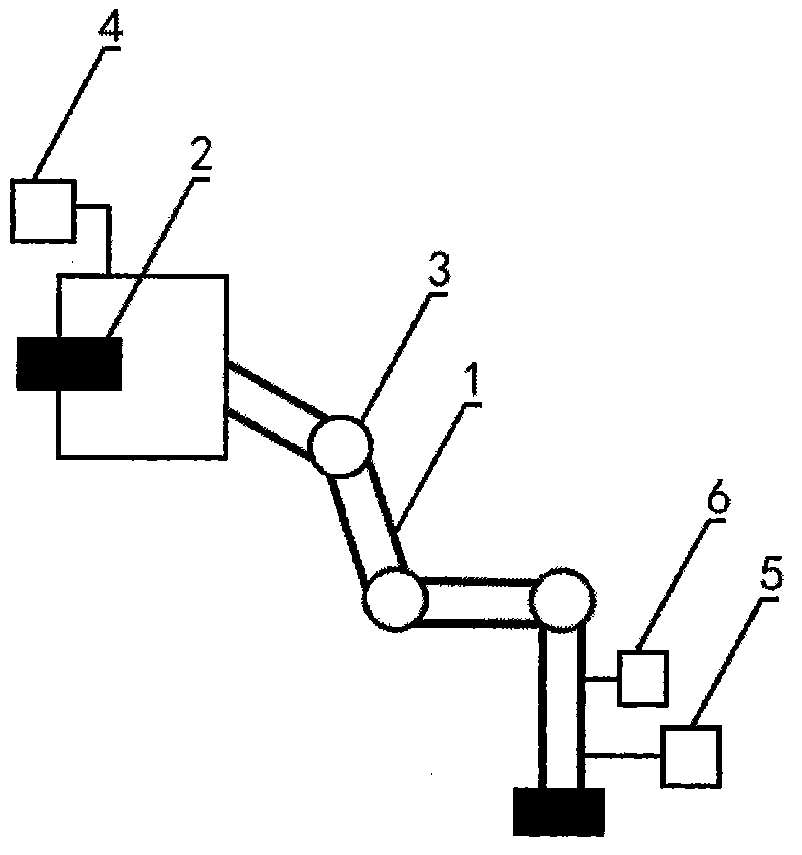

[0012] Embodiment: as shown in the accompanying drawing. The nail shooting machine in the bending direction includes a frame [1], a nail shooting component [2] is set on the frame, the frame is a multi-layer joint structure [3], and a video component is set on the nail shooting component [2]. 4], set the monitoring device [5] on the joint structure, the joint structure twists to a specific position during use, and determine the specific position on the monitoring device [5].

[0013] For the nail shooting machine in the bending direction, the nail shooting component [2] uses a high-pressure air source for setting operation.

[0014] For the nail shooting machine in the bending direction, a lighting component is set on the monitoring device [5], and a prompt message is sent out when the ambient light is insufficient.

[0015] For the nail shooting machine in the bending direction, a prompt device [6] is installed to prompt the progress and precautions.

[0016] For the nail s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com