Disc steel typewriter

A disc and steel number technology, applied in the field of disc steel number typewriters, can solve the problems of low structural precision, unstable transmission, etc., and achieve the effects of clear handwriting, long durability and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

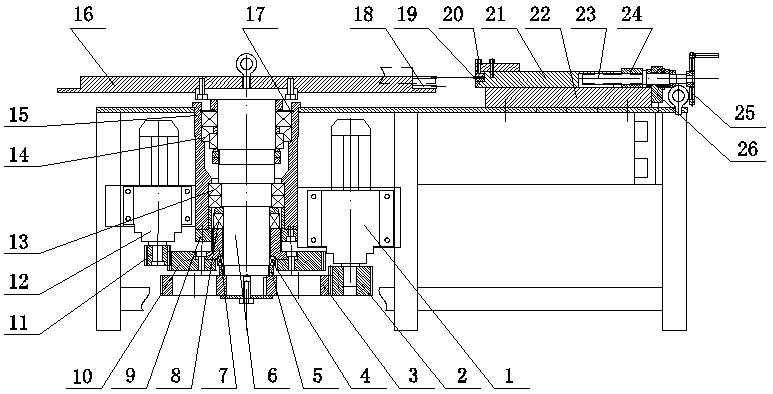

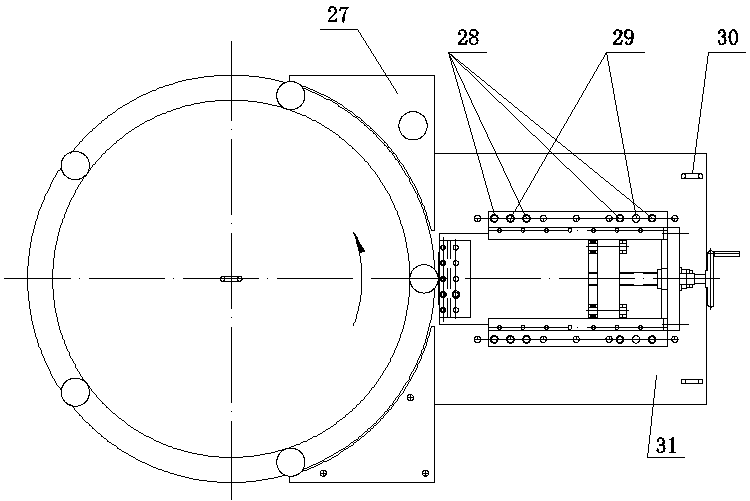

[0011] Such as figure 1 , 2 As shown, a disc steel typewriter includes a main shaft 6, a disc 16, a reduction motor I1, a reduction motor II12 and a typing device. A circlip 17 is provided, an upper cylindrical roller bearing 14 is arranged on the inner upper part of the bearing housing 15, a lower cylindrical roller bearing 13 is arranged on the inner lower part of the bearing housing 15, a moving wire ring 7 is fixed on the main shaft 6, and a moving wire ring 7 It is threadedly connected with the fixed wire ring 9 fixed on the bearing sleeve 15, the moving wire ring 7 is fixedly connected with the large gear I3 through bolts, and the large gear II10 meshes with the pinion II11 driven by the reduction motor II12; the lower end of the main shaft 6 is provided with a large Gear I3, large gear I3 meshes with pinion I2, and pinion I2 is driven by reduction motor I1; Main shaft 6 upper end is equipped with disc 16, and disc 16 upper side is provided with flange 18 to be typed; D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com