Automatic Adsorption Safety Prop System

A safety strut and adsorption-type technology, which is applied in the direction of inclined load-carrying vehicles, etc., can solve the problem that the safety strut cannot be operated by a single person, and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

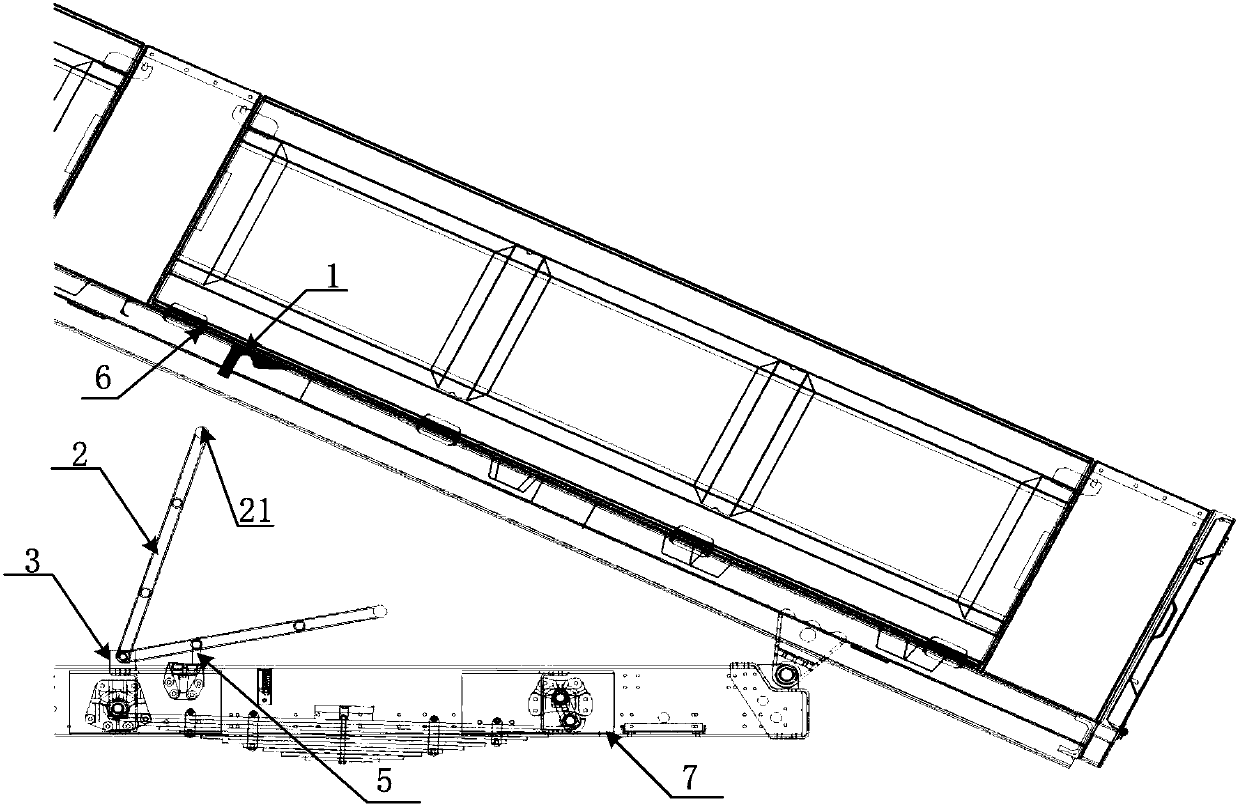

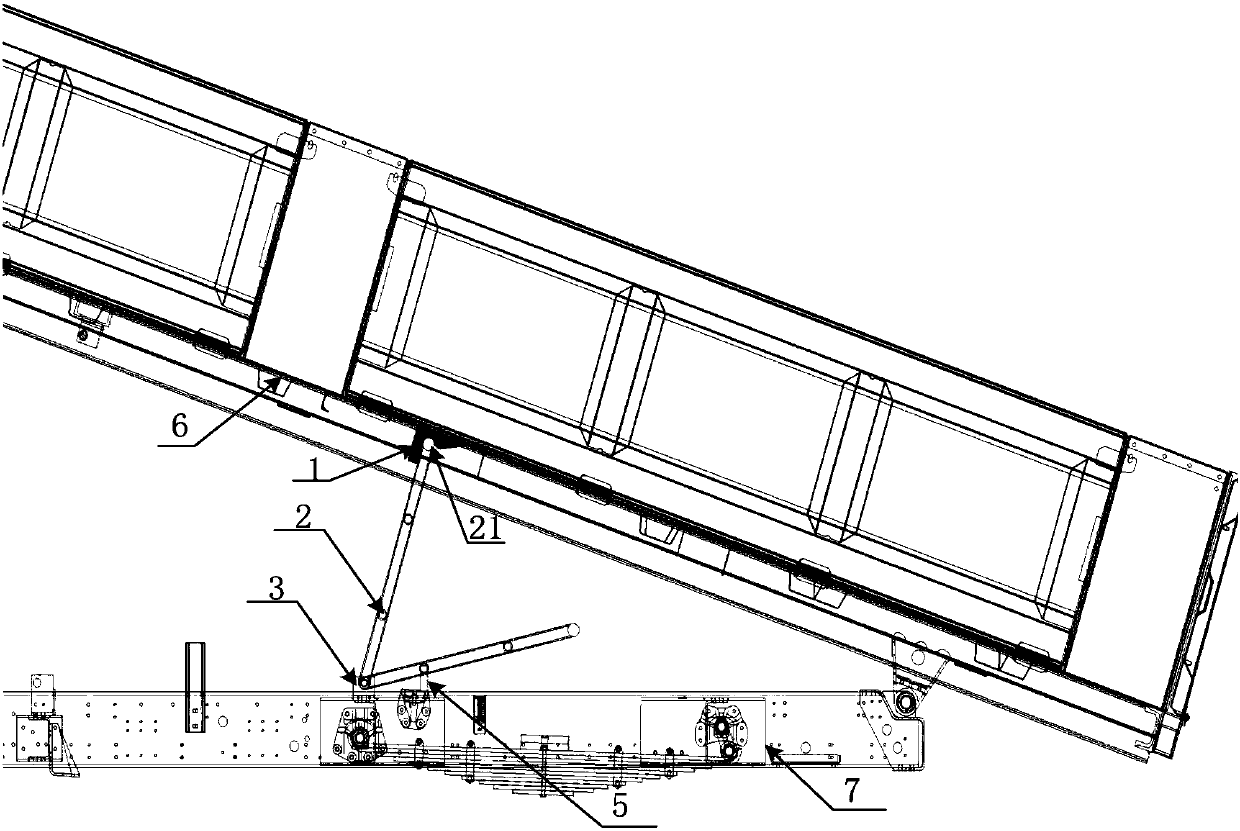

[0026] figure 1 and figure 2 It is a schematic structural diagram of the automatic adsorption type safety brace system provided in Embodiment 1 of the present invention. Such as figure 1 and figure 2 As shown, the automatic adsorption safety strut system includes an upper support base 1 , a support rod 2 , a lower support base 3 and a strut rotating base 5 .

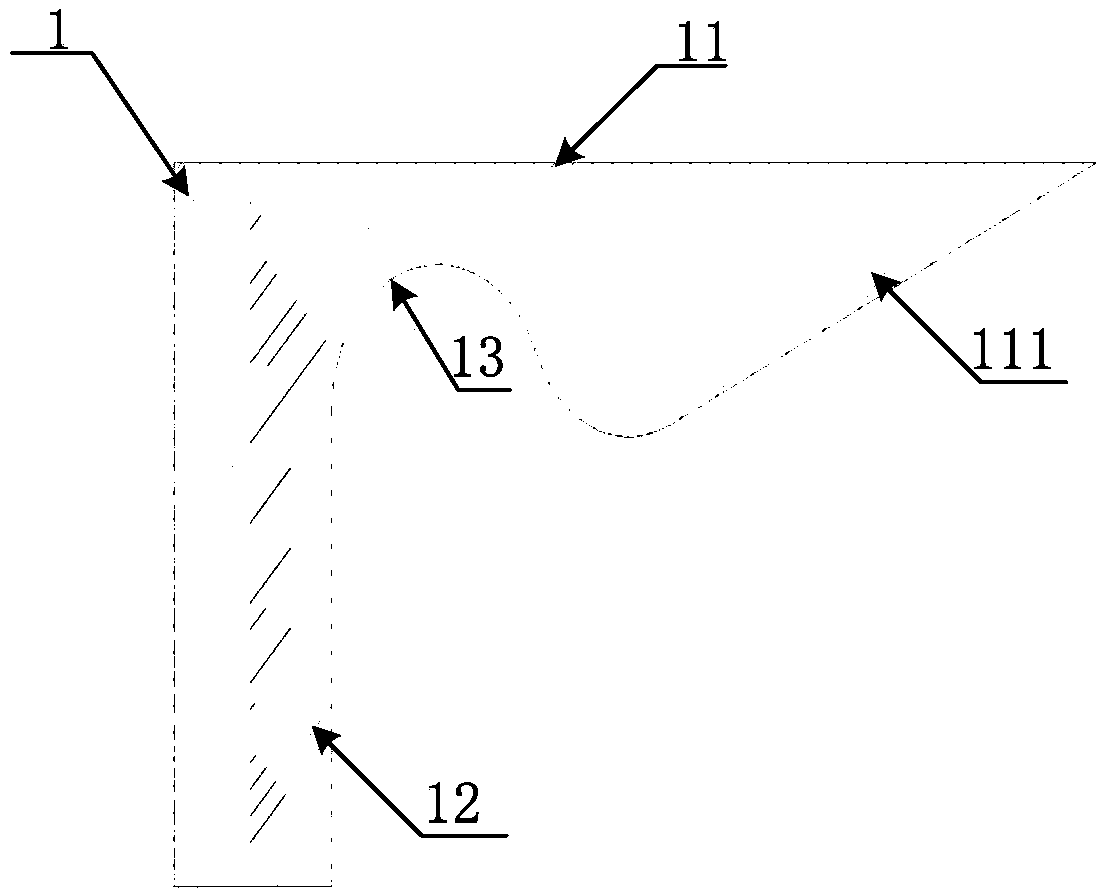

[0027] In this embodiment, the upper support seat 1 is made of magnetic material and fixedly mounted on the floor 6 of the carriage, specifically, as image 3 As shown, the upper support seat 1 includes a base plate 11 and a rib 12 perpendicular to the base plate 11, wherein the base plate 11 and the rib 12 are integrally formed, and the base plate 11 is provided with a transition bevel 111, between the transition bevel 111 and the rib 12 An arc-shaped groove 13 is provided, and the bottom plate 11 of the upper support seat 1 is fixedly installed on the compartment floor 6 . It should be noted that in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com