Poisonous slurry disposal method by replacing brine in salt rock old cavity with compressed air

A technology of compressed air and high-pressure air, which is applied in the direction of earthwork drilling, wellbore/well components, mining fluids, etc. It can solve the problems of repeated contact, brine pollution, and inability to solve brine pollution, and achieve the effect of avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

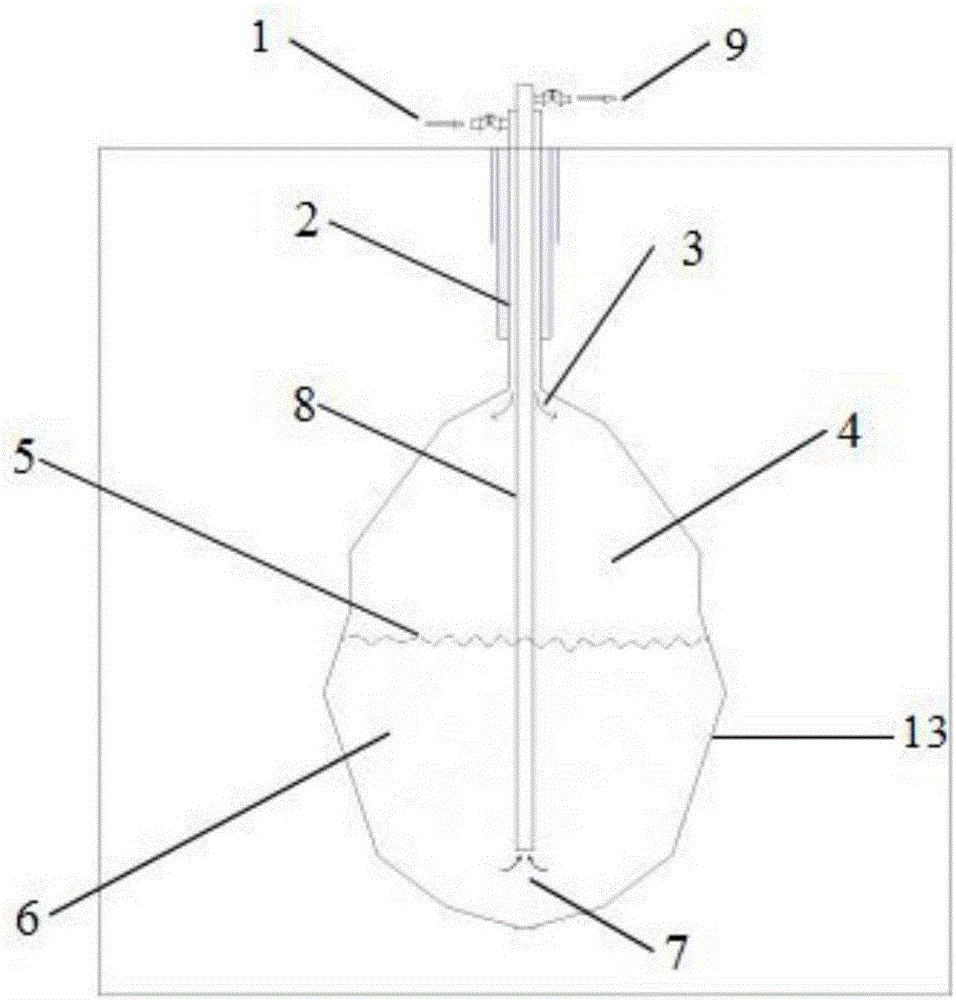

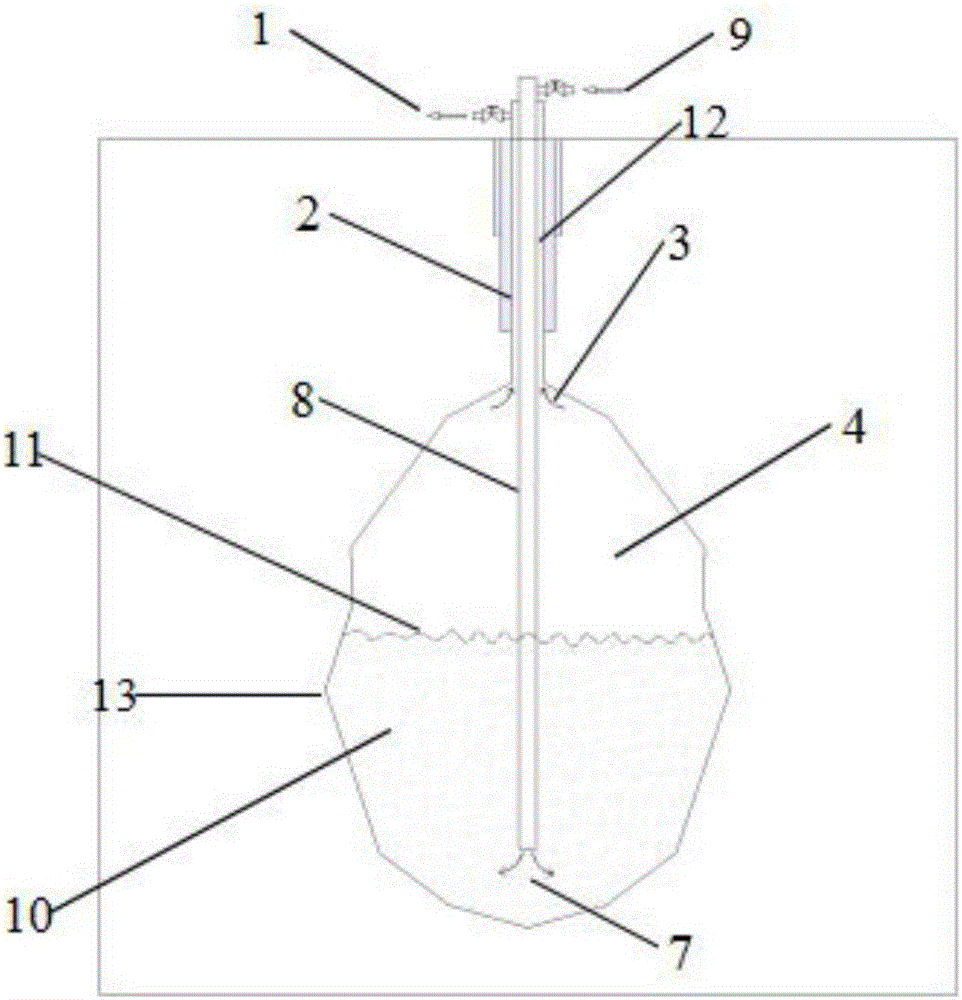

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] like figure 1 and figure 2 As shown: the present invention includes a central pipe and a technical sleeve, the technical sleeve penetrates between the abandoned salt chamber and the ground, the central pipe passes through the bottom of the technical sleeve located in the abandoned salt chamber, the There is a central pipe annular space between the central pipe and the technical sleeve. Specifically include the following steps:

[0022] ①Safety inspection stage of abandoned old salt rock wells: on-site inspection of well body integrity and cavity airtightness inspection of abandoned old salt rock cavity gas pressure test, to determine that the dissolved cavity and well body have good integrity and airtightness In order to obtain the original shape, horizon, geometric size and other information of the old cavity, sonar measurement is carried out on the cavity.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com