Oil fume separation extractor hood with purifier blade disc

A range hood and oil fume separation technology, which is applied in the range hood field, can solve the problems of increasing product cost and energy consumption, increasing power consumption, and laborious motor rotation, etc., achieving improved oil fume separation effect, enhanced stability and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

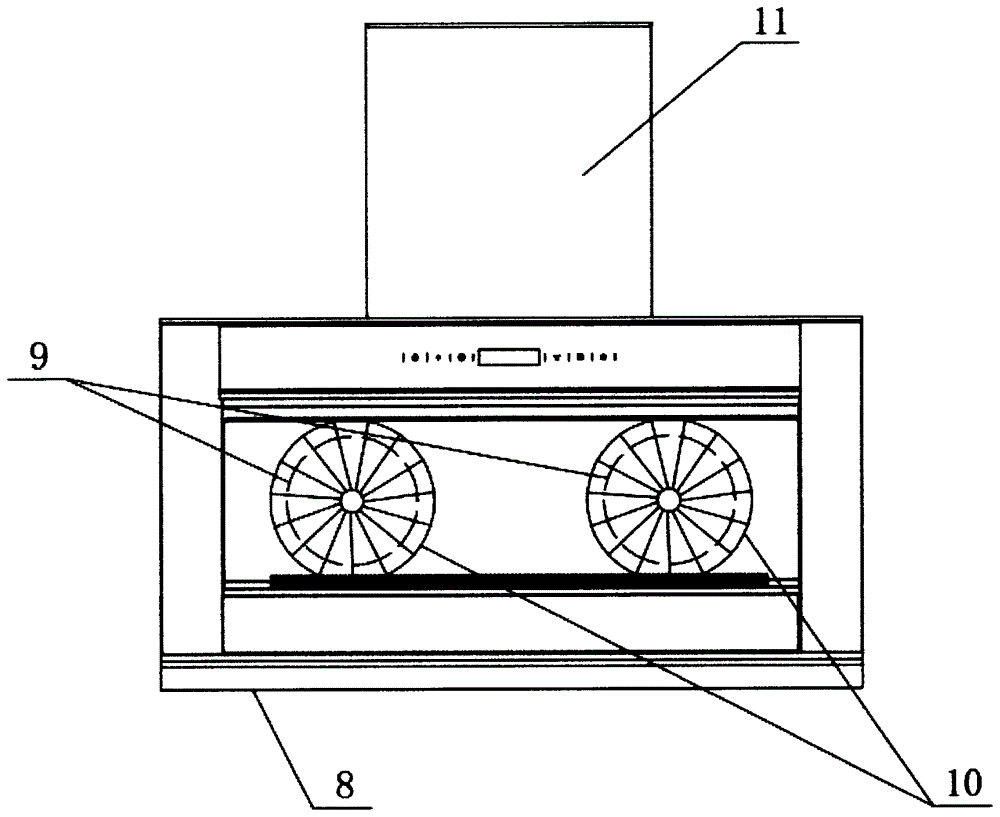

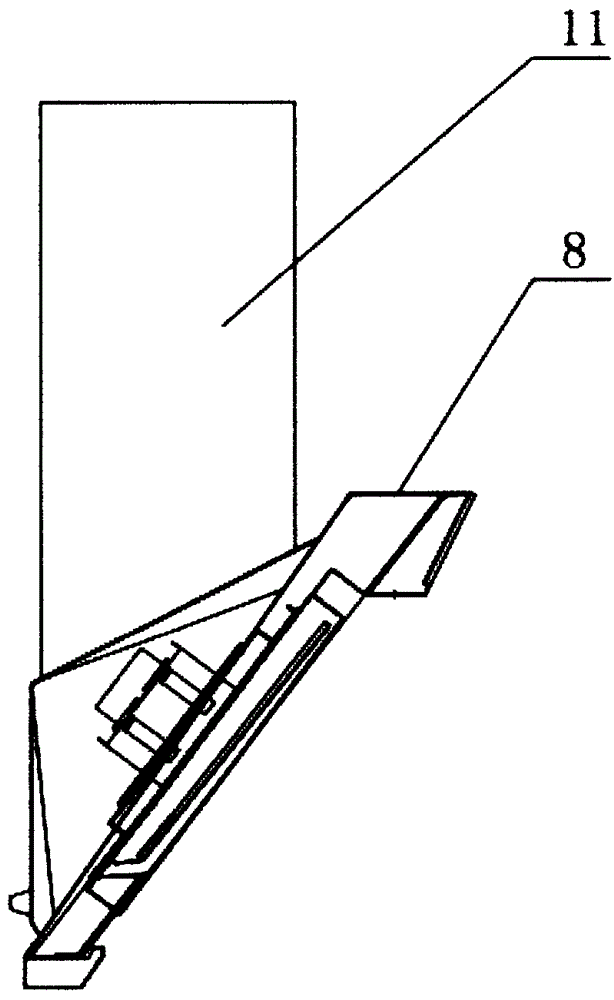

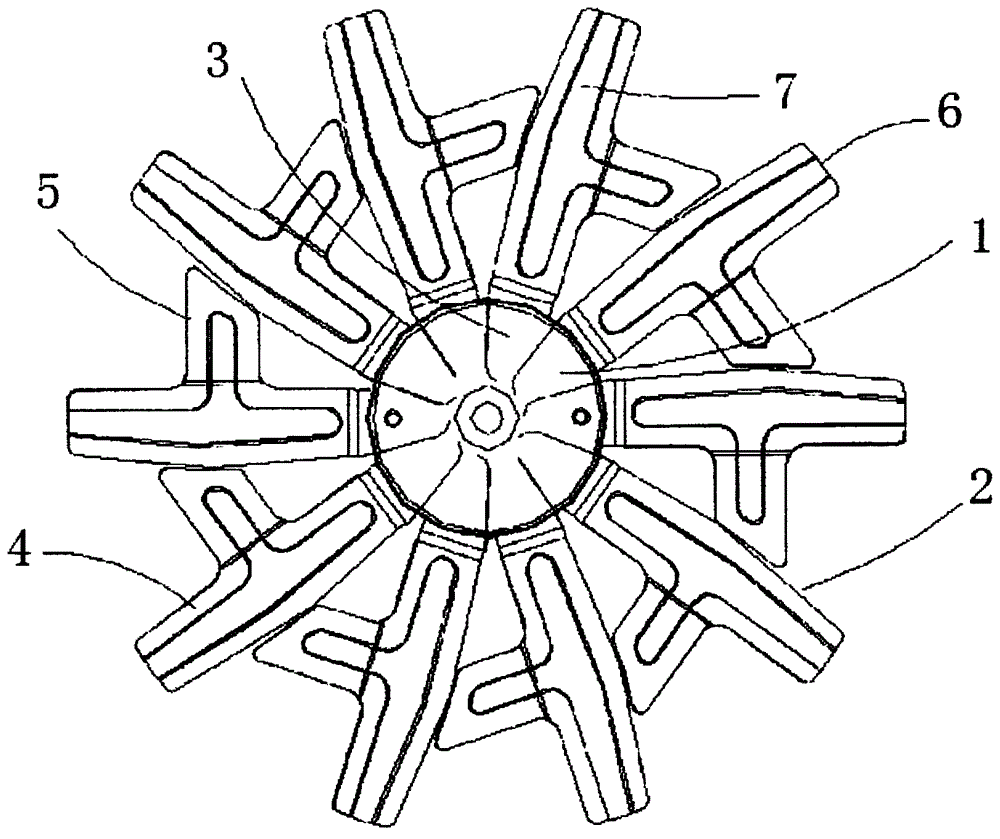

[0020] Such as Figure 1-Figure 5 As shown, a range hood with a purifier leaf disk capable of separating oil fumes according to this specific embodiment includes a range hood body, and the range hood body includes a casing 8, and the casing 8 A flue is arranged inside the upper end, and a cavity is arranged inside the casing 8. The bottom surface of the casing 8 is a shell plate, and smoking holes are respectively arranged on the left and right sides of the surface of the shell plate, and a net cover 10 is embedded in the smoking hole. The left and right sides of the inner wall of the shell plate are respectively provided with brackets, and the left and right sides of the two brackets are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com