Distributed optical fiber corrosion detecting device for wet devulcanizing chimney

A distributed optical fiber, wet chimney technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, analysis materials, etc., can solve the problems of the system losing the function of detection, the inner wall of the chimney is corroded, etc., to achieve simple and feasible construction and measurement. The effect of high distance accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

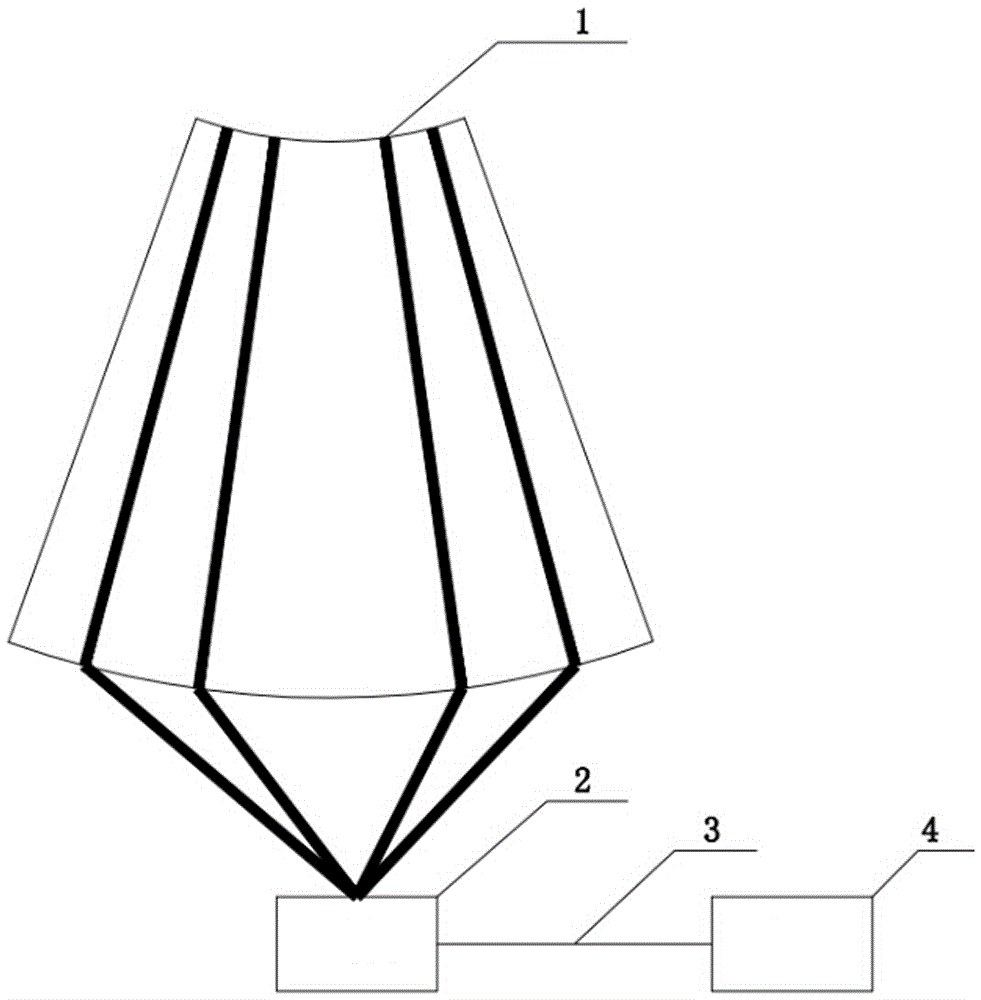

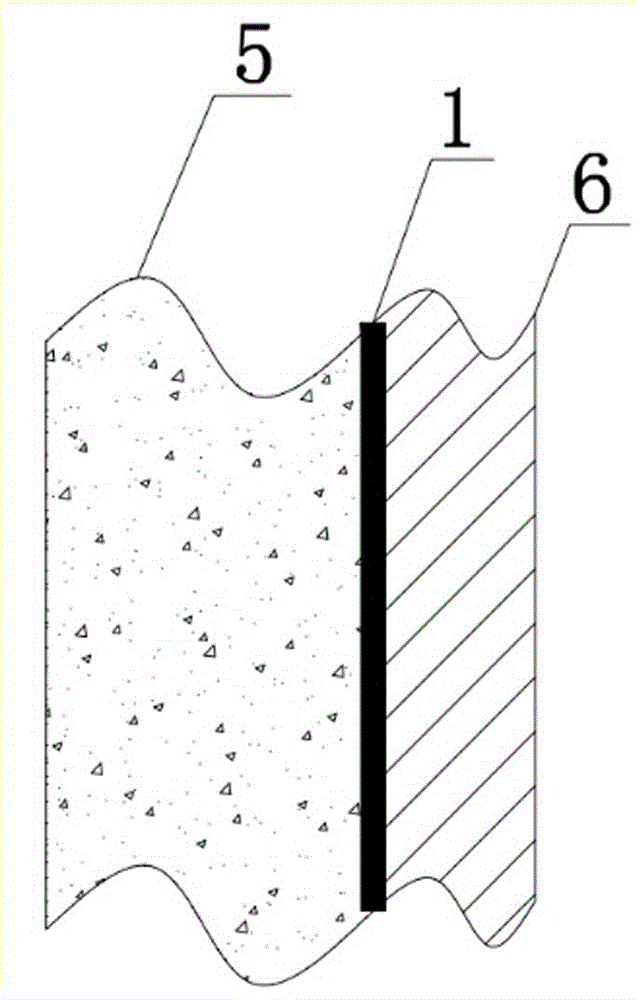

[0014] A distributed optical fiber corrosion detection device for desulfurization wet chimneys, including an optical fiber 1 arranged between the inner wall 5 of the chimney and an anti-corrosion material 6, one end of the optical fiber 1 is connected to a host 2, and the host 2 is connected to a host computer 4 through a communication line 3 . The optical fiber 1 runs through the upper and lower ends of the chimney, and the lower end of the optical fiber 1 protrudes from the ground and is connected to the host computer 2 . There are at least two optical fibers 1 and they are evenly distributed in the circumferential direction of the inner wall of the chimney 5 . The optical fiber 1 is a single-mode optical fiber or a multi-mode optical fiber.

[0015] like figure 1 — ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com