System and method for measuring relative deformation of soil layer rolled by road roller in real time

A relatively deformable, road roller technology, applied in radio wave measurement systems, measurement devices, satellite radio beacon positioning systems, etc., can solve problems such as poor accuracy, difficulty in achieving effective measurement, and inability to meet control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

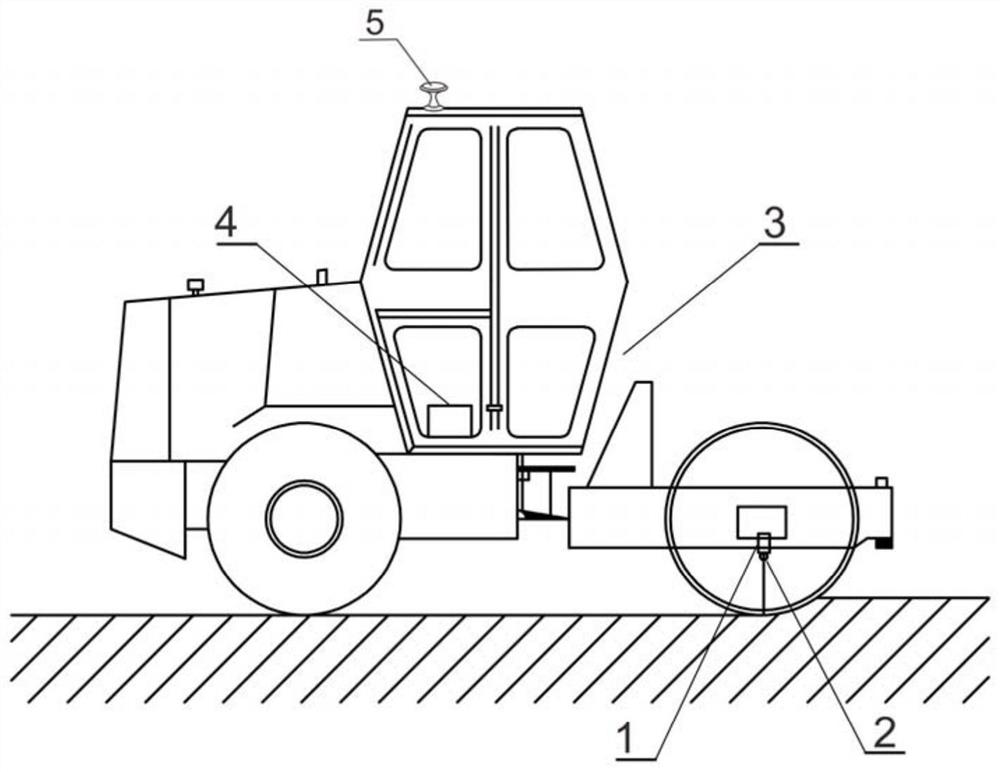

[0022] System and method for real - time measurement of roller rolling soil layer

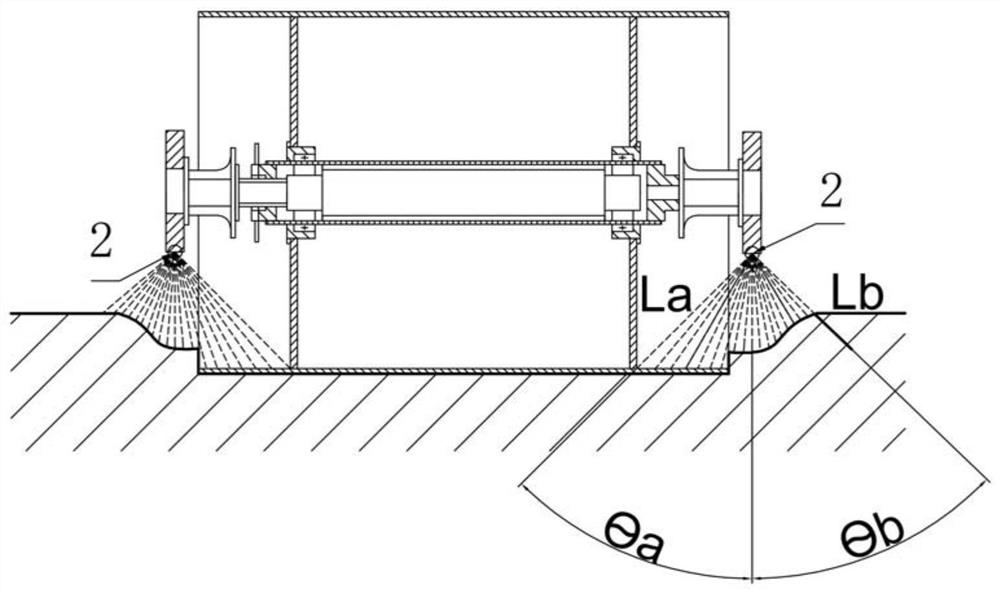

[0023] It is characterized in that the mounting frame 1, the laser scanning device 2, the GPS / BDS satellite positioning device 5, an on-board signal analyzer 4; mounting bracket is provided in the center of the roller 3 front wheel left and right axle, mounting laser scan on the mounting bracket. Device, the laser scanning device maintains a vertical attitude of the soil surface in the front-rear direction in the front-rear direction; the laser ray of the laser scanning device is scanned by the roller travel direction; the GPS / BDS satellite positioning device is set on the junction machine, at the roller Set an onboard signal analyzer in the driving platform;

[0024] The laser ray of the laser scanning device converts the real-time relative distance LA of the surface of the top surface of the collected front wheel, conversion to the difference between the real-time relative distance Lb of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com