Chromium alloy impact combination polished ring gear rotary table wheel backup clamp glass detection device

A technology of glass detection and chromium alloy, which is applied in the direction of measuring devices, testing material strength and instruments using one-time impact force, can solve the problems of operator injury, lack of uniformity, non-square, etc., and achieve the goal of improving operating efficiency and labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

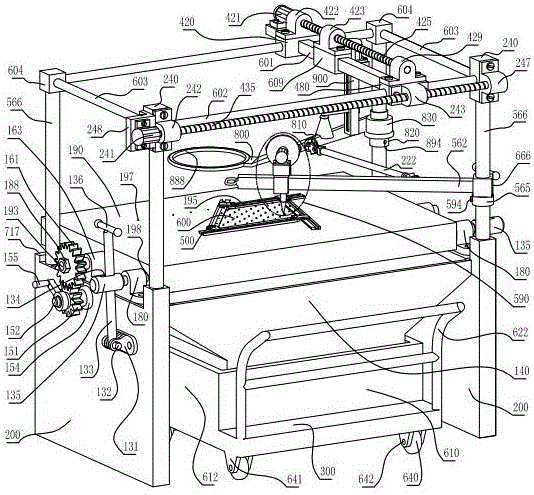

[0065] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

[0066] figure 1 Among them, the test turntable 190 is fixed with the wheel slideway corner clamp assembly 500, the wheel slideway corner clamp assembly 500 is fixed with the trapezoidal glass plate 600, and the rotary impact assembly 590 is located directly above the trapezoidal glass plate 600 and is in working condition.

[0067] Figure 4 , the rotary impact assembly 590 moves out of the trapezoidal glass plate 600 directly above and does not work, and the halo member 800 is located directly above the trapezoidal glass plate 600 and is in a working state.

[0068] Figure 7 In the process, the two sides of the wheel slideway corner are removed by the clamp assembly 500, and the test turntable 190 is in a tilted state, which facilitates the removal of glass fragments after the trapezoidal glass plate 600 is crushed.

[0069] Figure 8 The camera unive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com