Tray, carrying device, and semiconductor processing equipment

A carrier device and tray technology, which is applied in semiconductor/solid-state device manufacturing, metal material coating process, gaseous chemical plating, etc., can solve the problems of high investment cost, inability to limit the position of the substrate S, and crushing of the substrate. Achieve the effect of improving reliability and reducing the risk of crushing the radial dimension limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

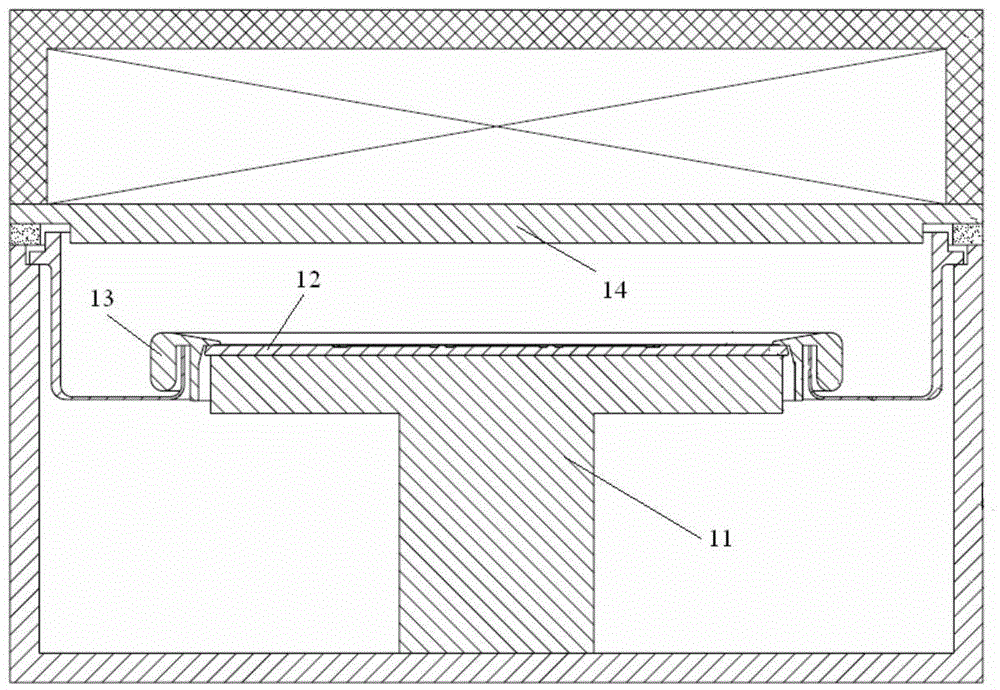

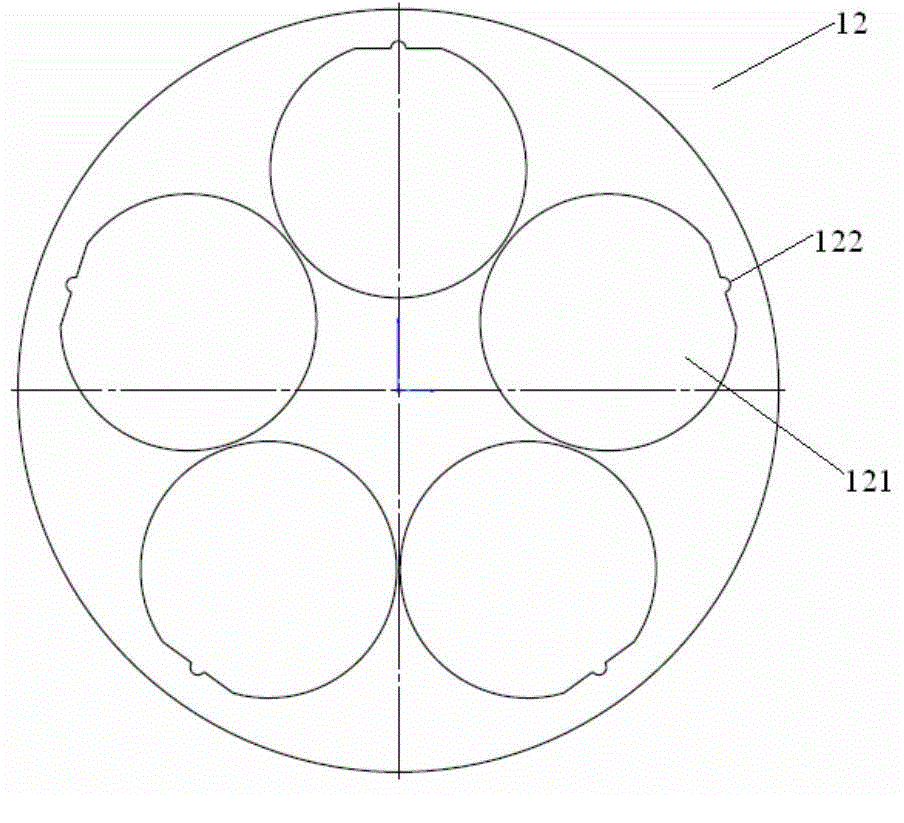

[0033] In order for those skilled in the art to better understand the technical solution of the present invention, the tray, the carrying device and the semiconductor processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

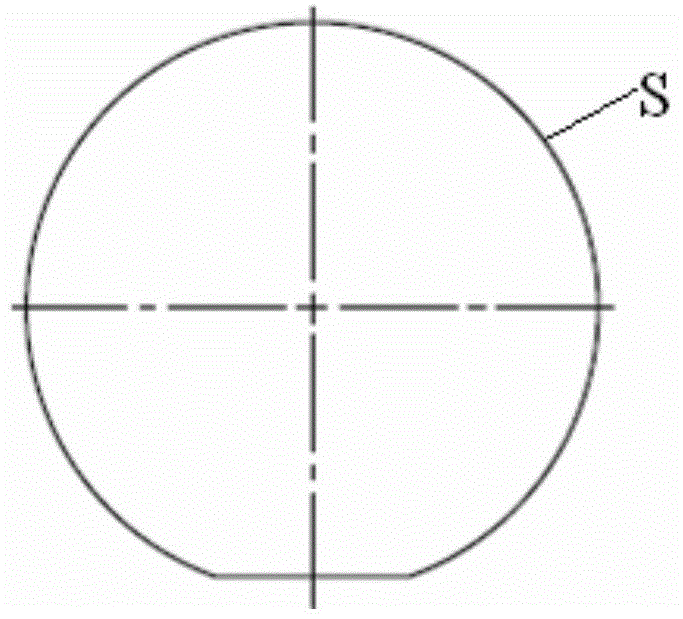

[0034] The tray provided in this embodiment is provided with at least one groove for accommodating the substrate and defining the placement direction of the substrate, the radial cross-sectional contour shape of the groove and the radial cross-sectional contour shape of the substrate are similar figures, The sidewall of the groove has a first corner, and the sidewall of the substrate has a second corner corresponding to the first corner. The so-called corner refers to a sharp corner formed by the contact of two surfaces. A first recess is provided at the position of each first corner on the side wall of the groove, and each first recess is used to accommodate the second corner of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com