All-purpose perforating machine

A technology of punching machine and hole knife, which is applied in metal processing and other directions, can solve the problems of manual damage, large processing quality, lack of guarantee, and large product loss, so as to improve quality and processing efficiency, avoid damage, and reduce product loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

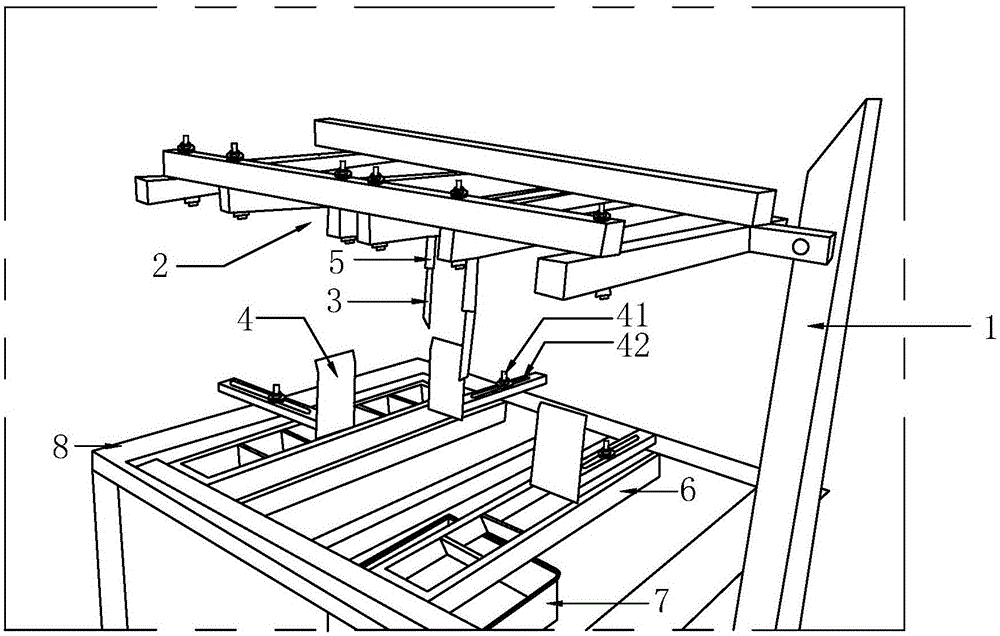

[0026] refer to figure 1 , a kind of universal punching machine of the present invention, comprises frame 1, punching knife 3 and the driving device for driving punching knife 3 punching operation, and described frame 1 upper side is provided with knife rest fixing device 2. The perforating knife 3 is installed on the knife holder fixing device 2, and the knife holder fixing device 2 is driven to move up and down by the driving device, and a platform 8 for placing materials is arranged on the lower side of the frame 1, and the platform 8 8 is provided with three positioning seats 4 arranged in a triangular shape to fix the cardboard. The above-mentioned devices together realize the mechanized operation of the carton punching operation. Compared with the traditional manual operation, the quality of the product and the processing are improved. Efficiency reduces product loss and avoids damage to human hands caused by manual work.

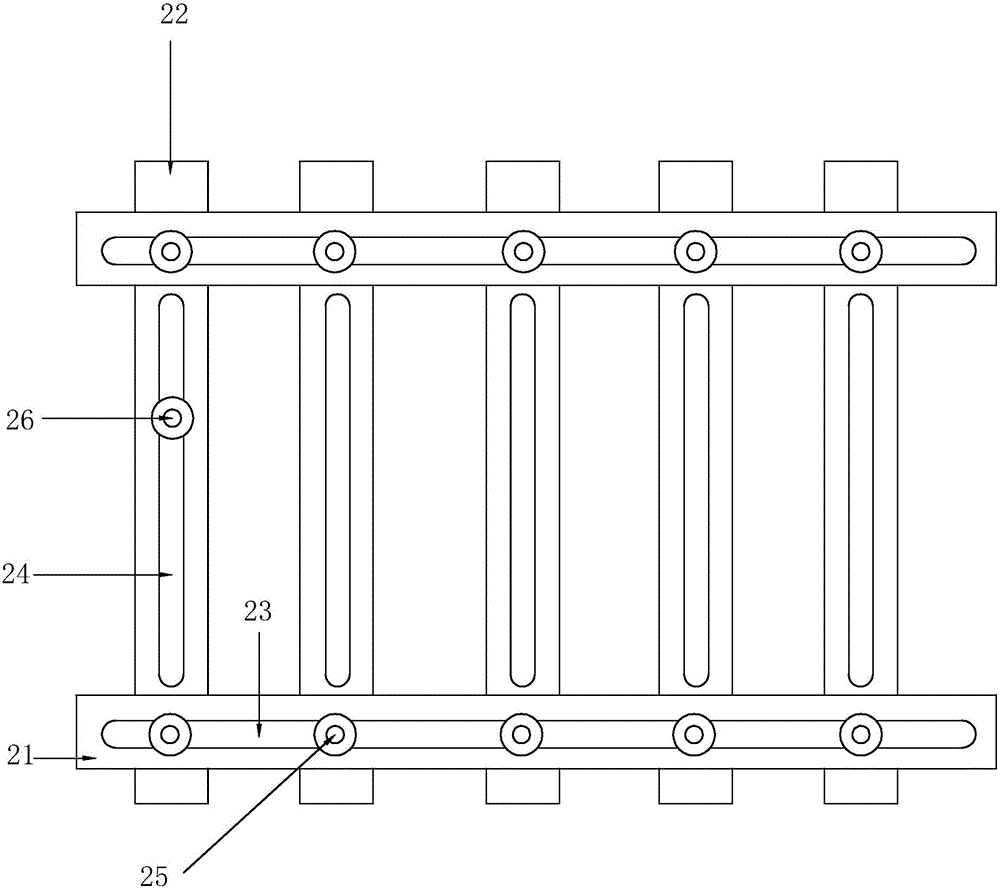

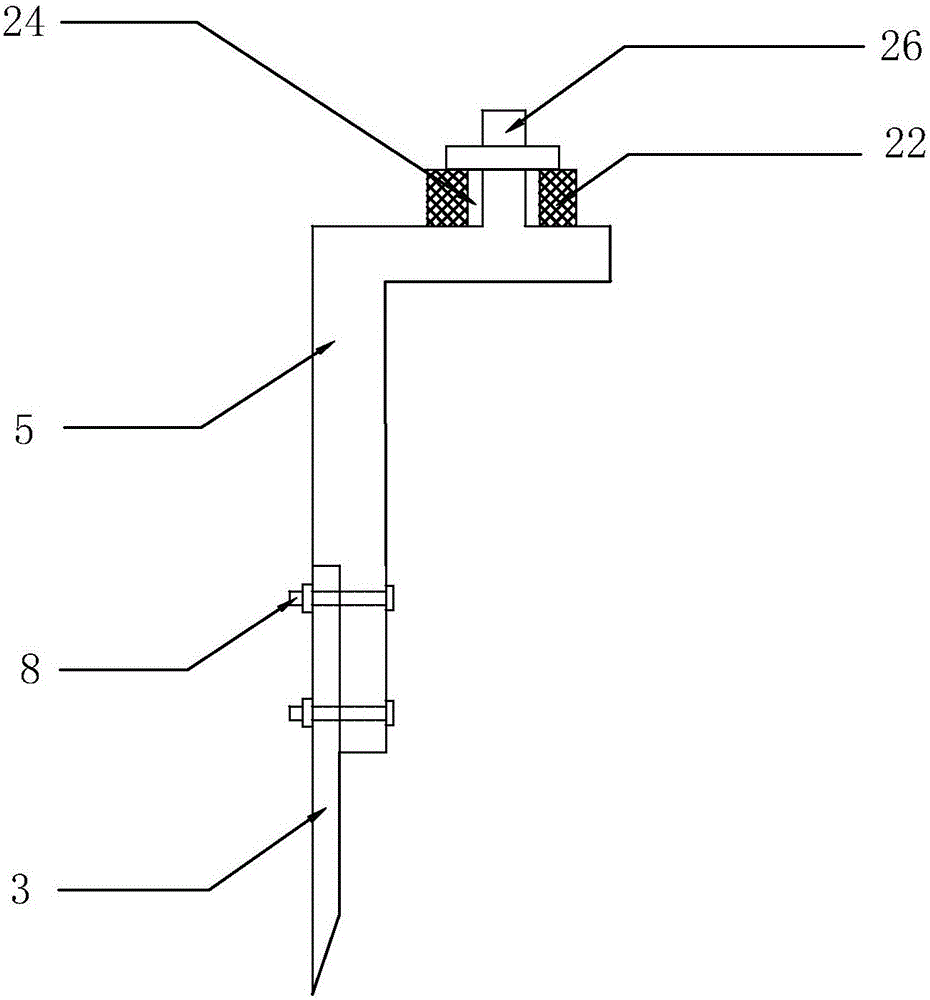

[0027] refer to figure 2 , the tool holder f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com