Three-station busbar processor positioning device

A busbar processing machine and positioning device technology, applied in positioning devices, feeding devices, storage devices, etc., can solve the problems of unguaranteed processing quality, low processing efficiency, slow operators, etc., to improve processing efficiency and Quality, good usability, improved efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

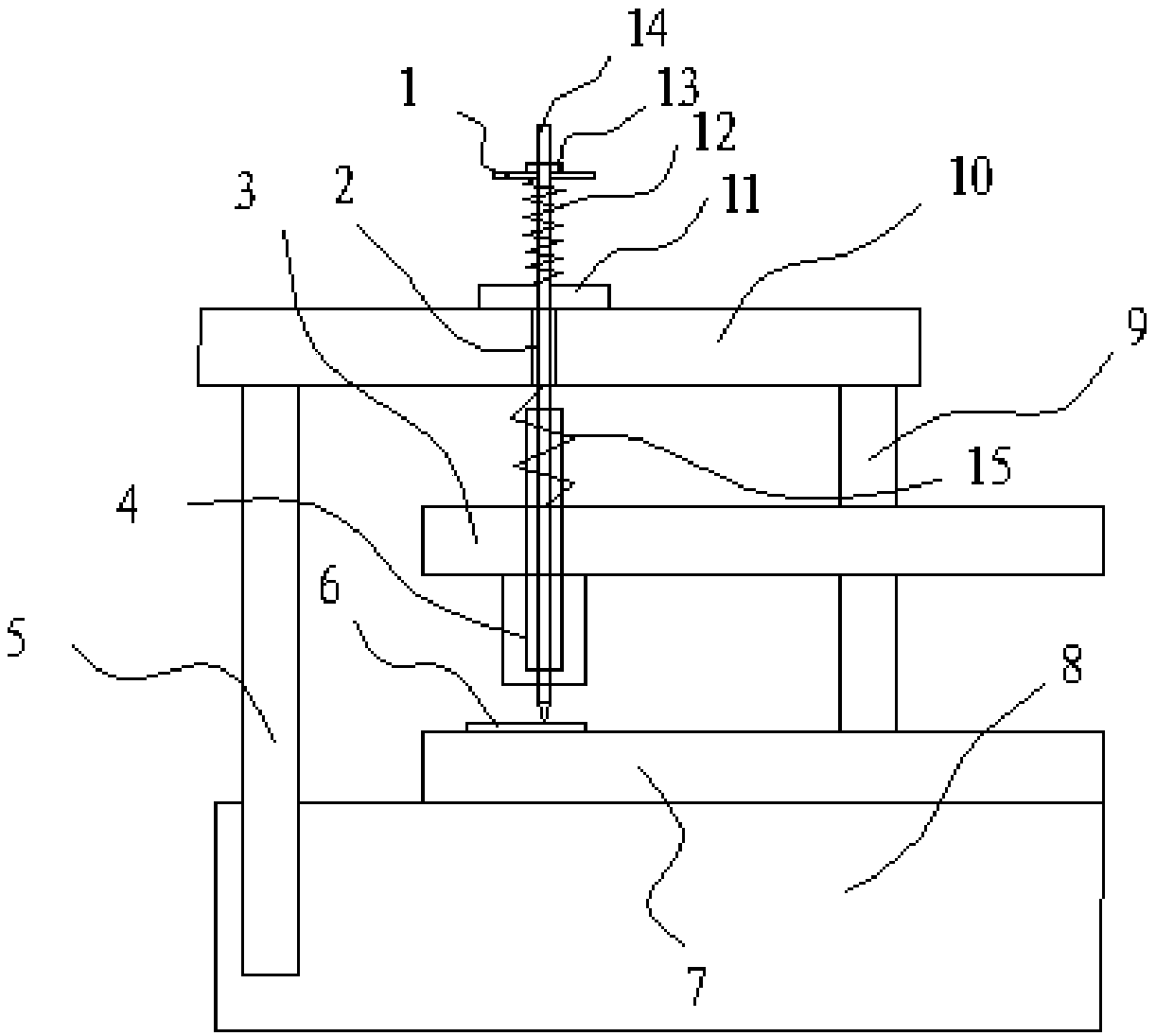

[0009] Embodiment 1: as attached figure 1 As shown, a positioning device for a three-station bus bar processing machine includes a machine base 8, a workbench 7, a tool rest 3 and a beam 10, and a workbench 7 is fixedly connected to the top of the machine base 8, and the workbench 7 A crossbeam 10 is arranged above the top of the crossbeam 10, a hydraulic cylinder one 5 and a hydraulic cylinder two 9 are respectively fixedly connected between the two ends of the crossbeam 10 and the machine base 8, and a rotatable knife is socketed outside the cylinder body of the hydraulic cylinder two 9 Frame 3, a blade 4 is provided below the knife rest 3, a spring one 15 is fixedly connected above the blade 4, and a spring one 15 is positioned under the crossbeam 10, and a vertical rod hole 2 is provided in the middle of the crossbeam 10, Positioning rod 14 is arranged in rod hole 2, and the bottom end of described positioning rod 14 passes through the through hole in the middle of spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com