A preparation method of transparent mesoporous titanium dioxide hydrophobic/superhydrophilic functional film

A technology of mesoporous titanium dioxide and hydrophobic film, applied in the direction of coating, can solve the problem of few preparation methods, and achieve the effect of simple process, easy operation and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

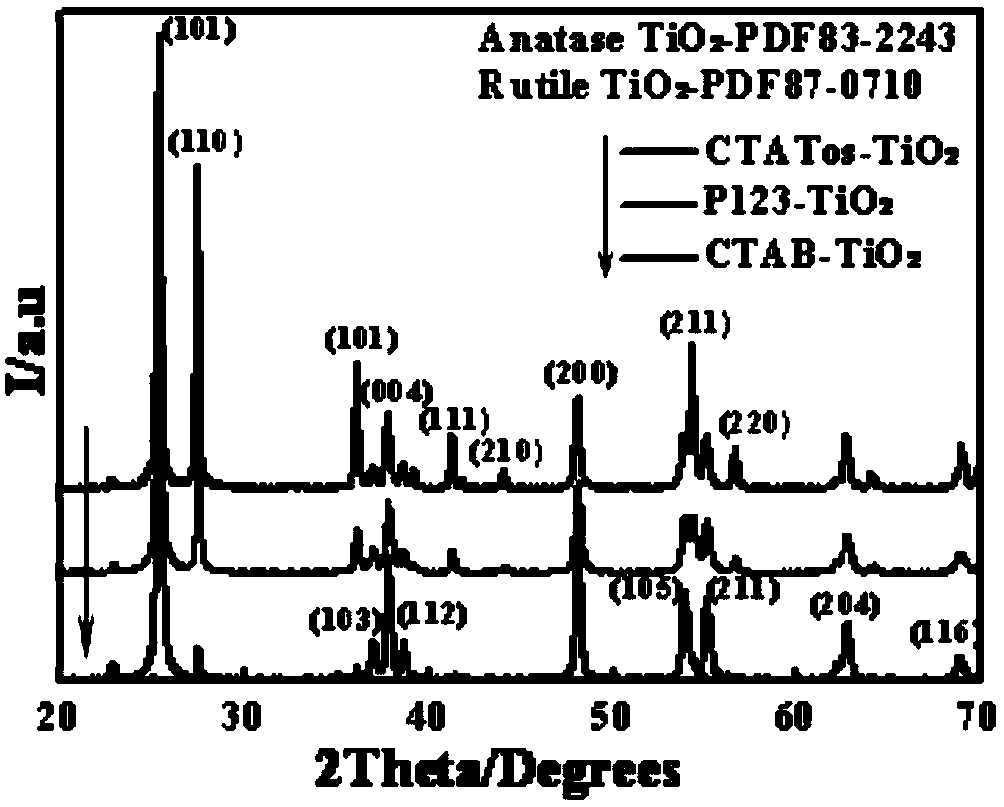

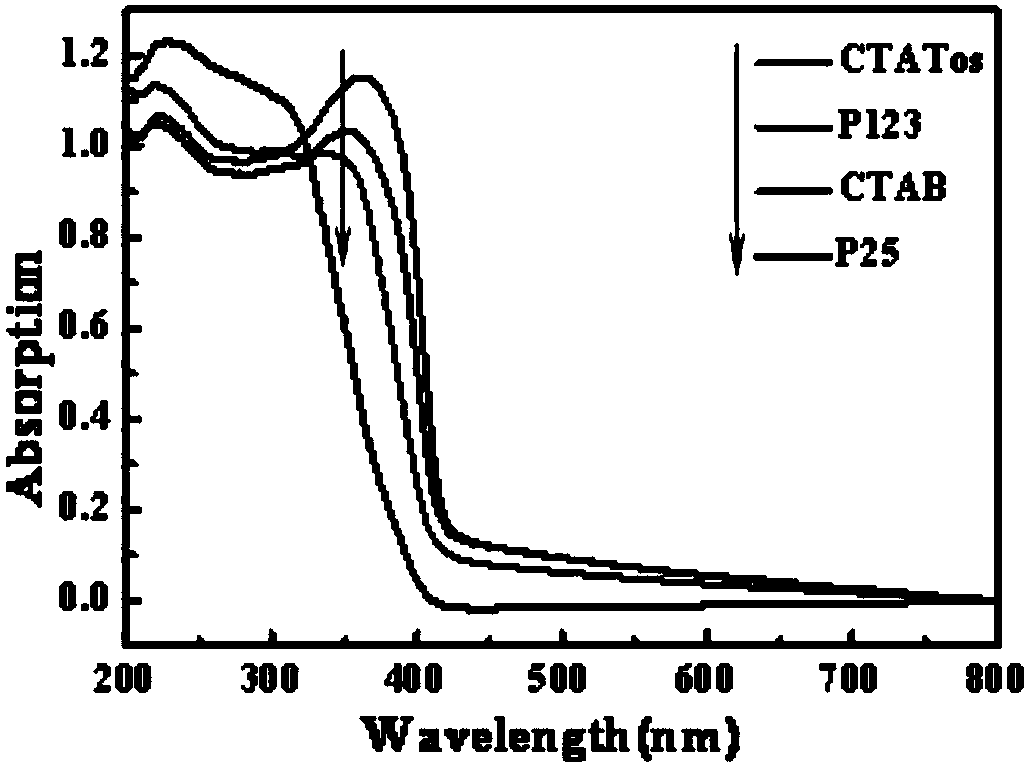

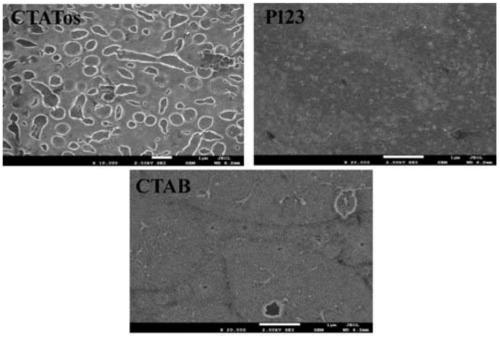

[0068] Example 1 CTATos-TiO 2 superhydrophilic film

[0069] 1) 8.00 g of butyl titanate was diluted in 40 g of ethylene glycol, and 1.21 g of acetylacetone was added as a stabilizer to prepare solution A;

[0070] 2.00g CTATos surfactant was dissolved in 35g ethylene glycol and 0.18g water to prepare solution B;

[0071] Under magnetic stirring, add B dropwise to A, and use concentrated nitric acid to adjust the pH of the mixture to 3;

[0072] Stirring was continued for 2 h at room temperature to obtain a stable sol, which was stored at room temperature.

[0073] 2) The above-mentioned sol was evenly sprayed on a smooth ceramic substrate by ultrasonic spraying method, slightly air-dried, and placed in a muffle furnace for calcination at 600°C for 2 hours to obtain a CTATos-TiO2 superhydrophilic film.

[0074] In this embodiment, the molar ratio of water / titanium in the sol is 0.43, and the molar ratio of alcohol / titanium is 51.

Embodiment 2

[0075] Embodiment 2 P123-TiO2 superhydrophilic film

[0076] 1) 8.00 g of butyl titanate was diluted in 35 g of ethanol, and 1.21 g of acetylacetone was added as a stabilizer to prepare solution A;

[0077] 1.70g P123 surfactant was dissolved in 30g ethanol and 0.43g water to prepare solution B;

[0078] Under magnetic stirring, add B dropwise to A, and use concentrated nitric acid to adjust the pH of the mixture to 4;

[0079] Stirring was continued for 2 h at room temperature to obtain a stable sol, which was stored at room temperature.

[0080] 2) Spray the above sol evenly on a smooth glass substrate by compressed air spray method, air-dry it slightly, and place it in a muffle furnace for calcination at 500°C for 2 hours to obtain P123-TiO 2 superhydrophilic film.

[0081] In this embodiment, the molar ratio of water / titanium in the sol is 1.02, and the molar ratio of alcohol / titanium is 60.

Embodiment 3

[0082] Example 3 CTAB-TiO 2 Hydrophobic film

[0083] 1) 8.00 g of butyl titanate was diluted in 40 g of n-butanol, and 1.21 g of acetylacetone was added as a stabilizer to prepare solution A;

[0084] 2.00g of CTAB surfactant was dissolved in 35g of n-butanol and 0.72g of water to obtain solution B;

[0085] Under magnetic stirring, add B dropwise to A, and use concentrated hydrochloric acid to adjust the pH of the mixture to 3;

[0086] Stirring was continued for 2 h at room temperature to obtain a stable sol, which was stored at room temperature.

[0087] 2) The above-mentioned sol was uniformly sprayed on a smooth ceramic substrate by compressed air spraying method, air-dried slightly, and placed in a muffle furnace for calcination at 600°C for 2 hours to obtain a CTAB-TiO2 hydrophobic film.

[0088] In this embodiment, the molar ratio of water / titanium in the sol is 1.70, and the molar ratio of alcohol / titanium is 43.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com