Pressure measuring device self-carried by individual hydraulic prop

A single hydraulic prop and pressure measuring device technology, applied in props/supports, mining equipment, earthwork drilling, etc., can solve problems such as hydraulic oil leakage, damage to the three-purpose valve, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following combination Attached picture right invention The specific implementation manner is described in detail.

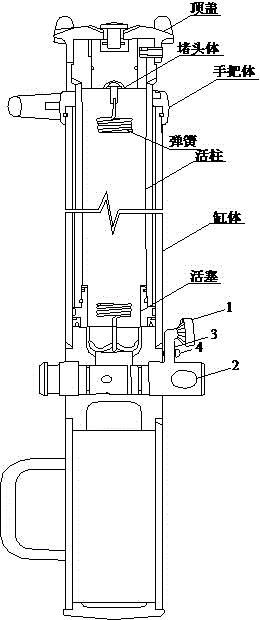

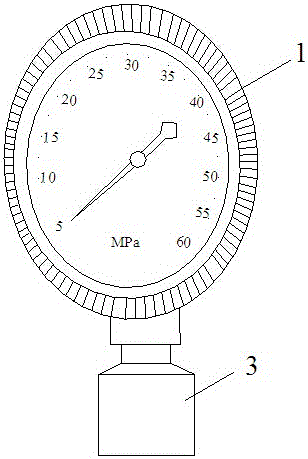

[0012] Depend on picture 1-5 give, ben invention Including the main body of the single hydraulic prop, the pressure stabilizing valve (4), the conduit (3), the hydraulic surface( 1), the pressure stabilizing valve (4), the hydraulic pressure and the hydraulic pressure during work surface( 1) connected together, when the hydraulic surface( 1) Block hydraulic transmission during replacement and maintenance.

[0013] The design parameters of the pressure stabilizing valve (4) are the same as those of the single hydraulic prop, and the tools are matched during installation and maintenance.

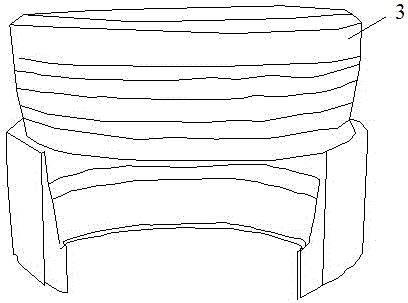

[0014] The conduit (3) and the hydraulic surface( 1) It is threaded connection, and the thread of cutting conduit (3) is internal thread. structure as shown in the picture 4 shown.

[0015] In order to achieve the use effect, the self-contained press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com