Detection device for deviation of guide belt in cloth drying machine

An offset detection and cloth drying technology, applied in drying, drying solid materials, lighting and heating equipment, etc., can solve the problems of the dryer not running normally, the detection being insensitive, and affecting the normal transmission of the guide belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

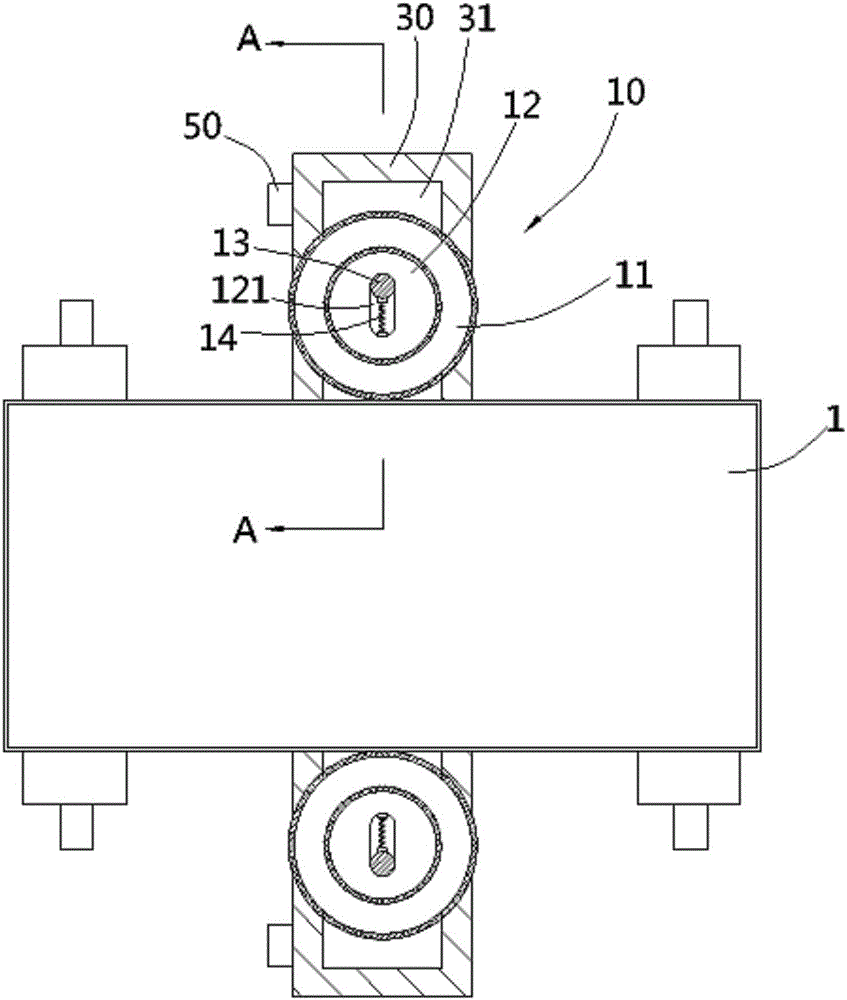

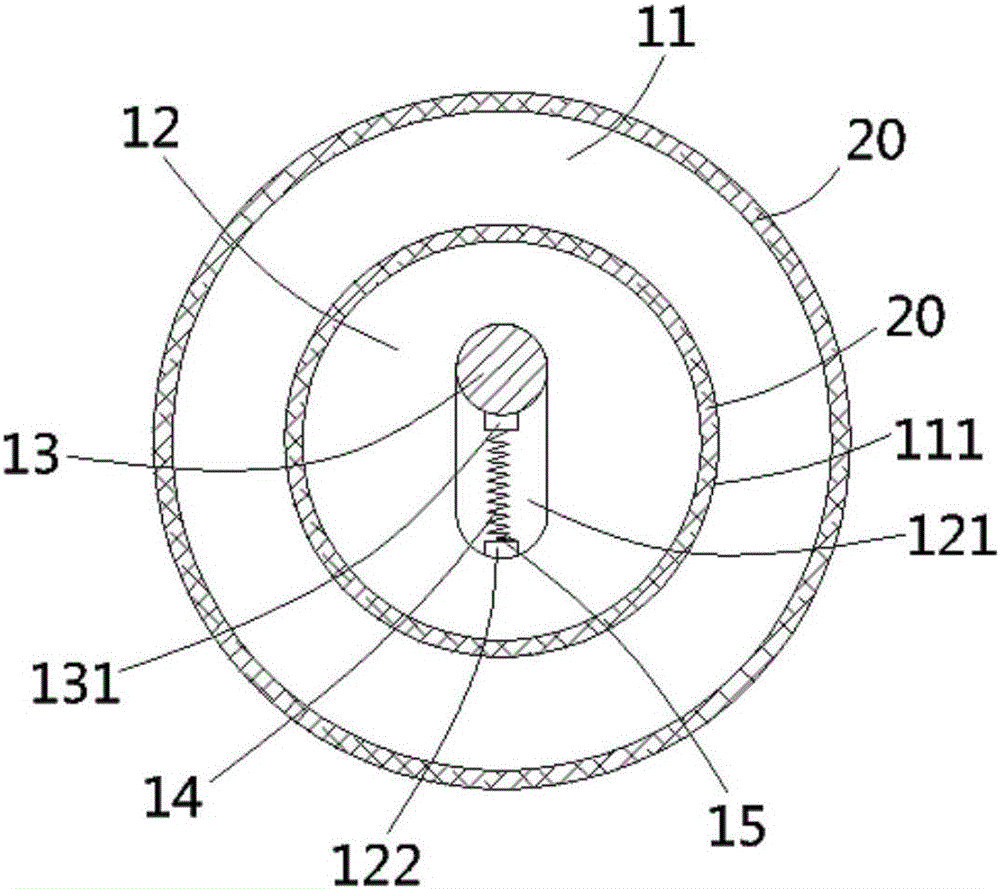

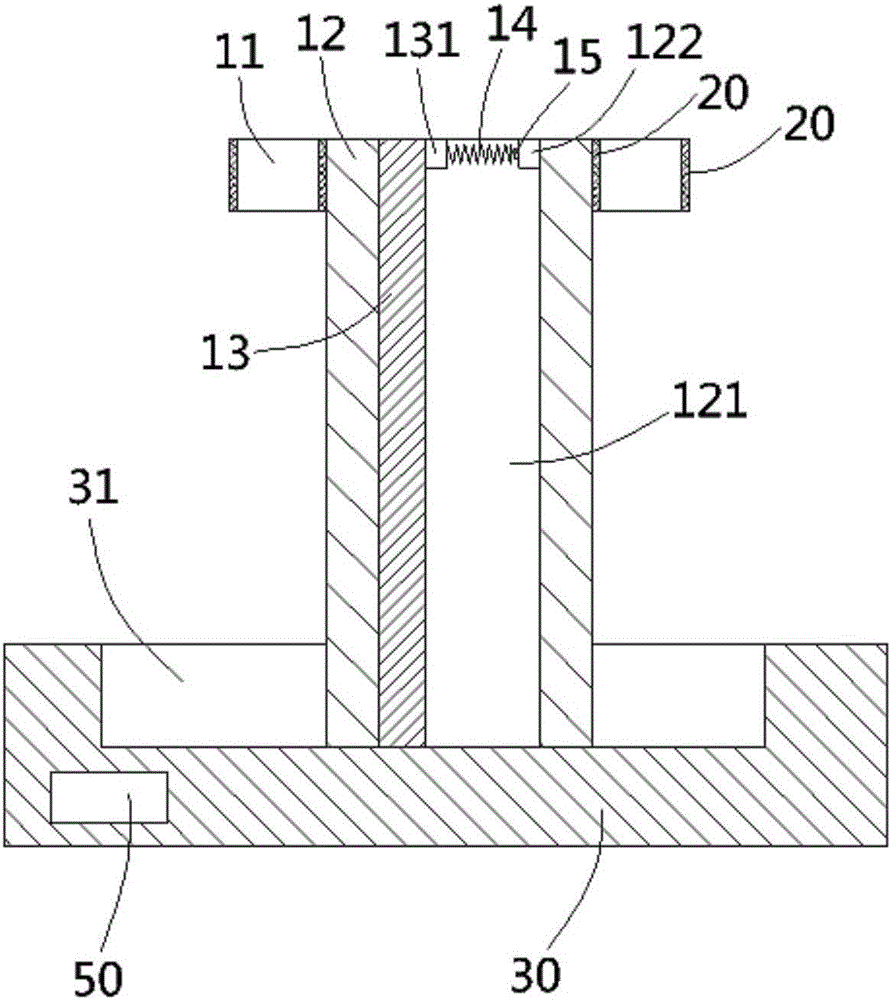

[0020] see Figure 1 to Figure 3 , the deviation detection device of a guide belt in a cloth dryer according to the present invention includes two detection mechanisms 10 symmetrically arranged on both sides of the guide belt 1; the detection mechanism 10 includes a pulley 11, a detection shaft 12 , a fixed shaft 13, a detection spring 14 and a pressure sensor 15, the said idler 11 leans against the side of the guide belt 1, the idler 11 is sleeved on the said detection shaft 12, and the middle part of said idler 11 is formed There is a through hole 111, the detection shaft 12 is inserted into the through hole 111, the inner side wall of the through hole 111 and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com