Clamping mechanism of hub leak tester

A technology of clamping mechanism and leak testing machine, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problem of easy breakage of the tie rod 3, flying out of the hub, breakage of the tie rod, etc. problems, to achieve structural safety, ensure production safety, and avoid potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

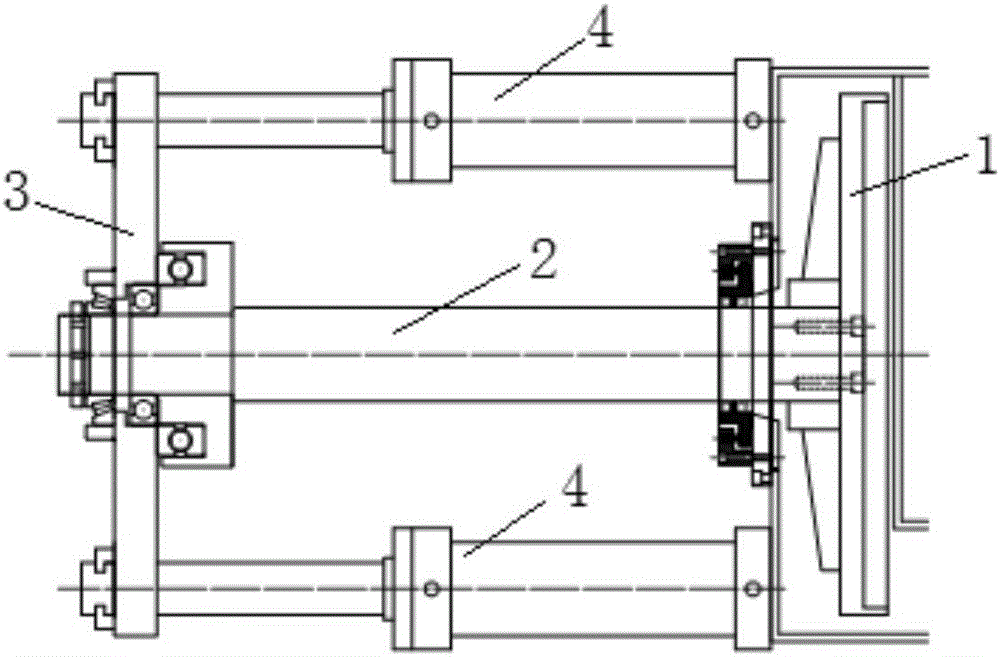

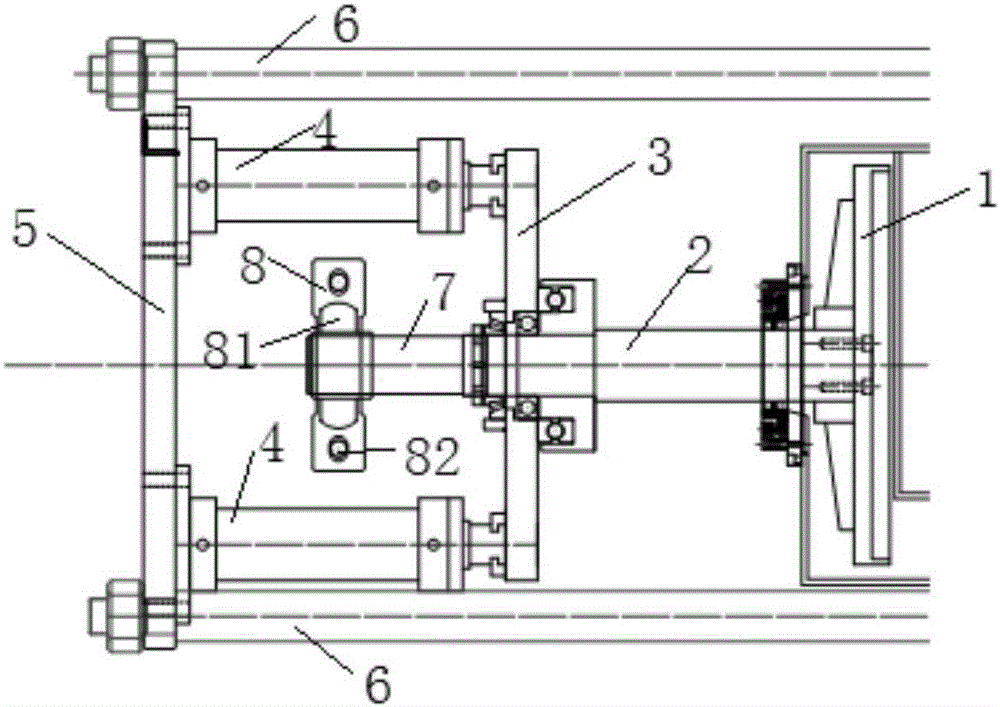

[0020] pass below figure 2 and specific embodiments to further illustrate the technical solution of the present invention.

[0021] Such as figure 2 As shown, the clamping mechanism of the wheel hub leak tester of the present invention includes two clamping devices that are symmetrically and coaxially arranged. For the chuck 1 of the tight hub, the central axis of the tie rod 3 is perpendicular to the central axis of the main shaft 2, and the central axis of the chuck 1 is parallel to the central axis of the main shaft 2; The main shaft 2 is respectively arranged on both sides of the pull rod 3, and a fixed plate 5 is connected between the ends of the two oil cylinders 4, and the two ends of the fixed plate 5 are respectively connected with the fixed shaft 6 of the hub leak tester, and the fixed shaft 6 The central axis of is parallel to the central axis of main shaft 2. When the clamping mechanism of the hub leak testing machine of the present invention is in operation, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap