Circular whole loop tunnel structure test device

A technology of tunnel structure and test device, which is applied to the testing, measuring device, instrument and other directions of machine/structural components, can solve the problems of reduced cost of test device, limited versatility and high cost, and achieves excellent versatility, The effect of easy installation or removal and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

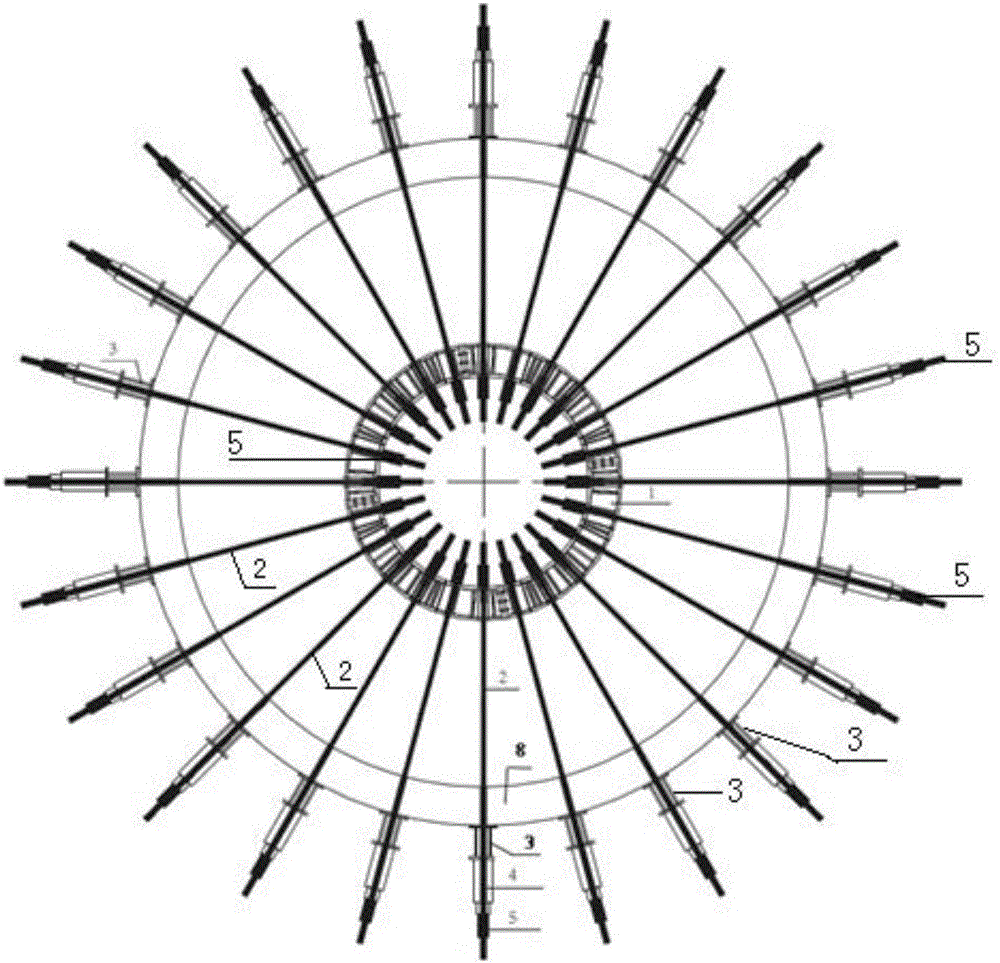

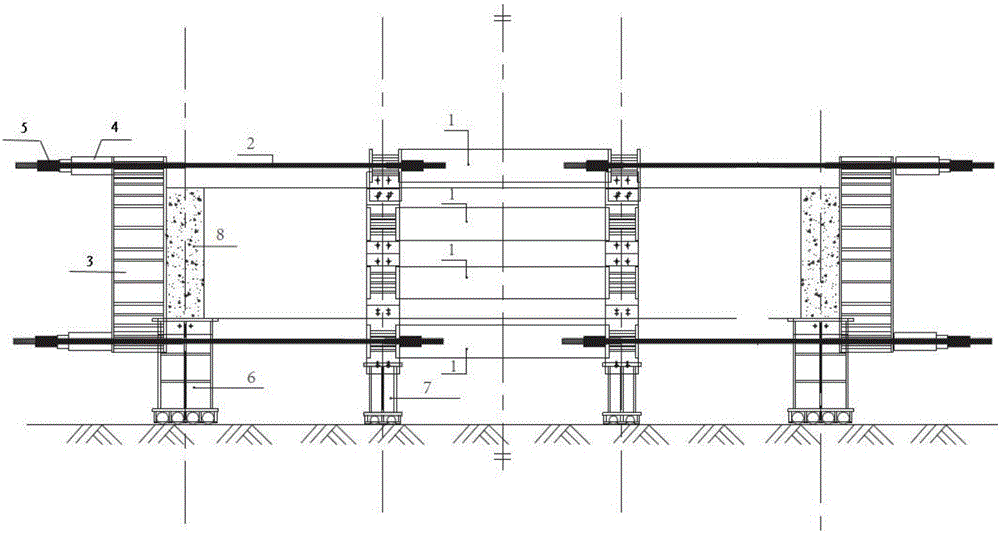

[0018] The top view of the test device is as figure 1 shown in the structure, image 3 just for understanding figure 2 The positional relationship between ring beams and segments.

[0019] In this embodiment, a test device for a circular full-ring tunnel structure includes a ring beam module, a circular full-ring tunnel segment 8, 48 tie rods 2, 24 tension beams 3, 48 jacks 4, and nuts 5 , sliding support A, sliding support B, bolt splicing plate 9,

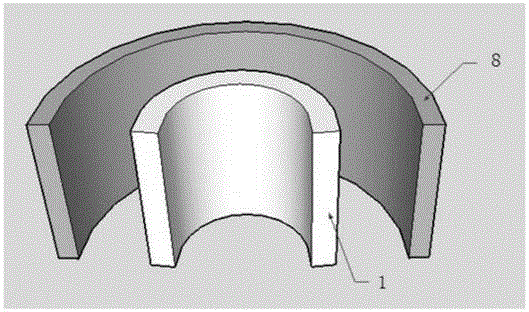

[0020] The ring beam module and segment 8 are two concentric circle structures, the ring beam module is on the inner side, and the circular full-ring tunnel segment 8 is on the outside. The circular full-ring tunnel segment 8 is placed on the sliding support A, The ring beam module is placed on the sliding support B,

[0021] The ring beam module described in this embodiment is composed of upper and lower four-layer ring beam units 1 superimposed, and the upper and lower adjacent ring beam units 1 are connected by bolt splic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com