Cable tension buffer device for engineering machinery

A technology of construction machinery and buffer device, which is applied in the field of electricity transmission, can solve the problems of high energy consumption, serious pollution, the internal combustion engine cannot give full play to the internal combustion engine and hydraulic system, etc., and achieves the effect of safe and convenient cable connection and maintenance, and convenient connection operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

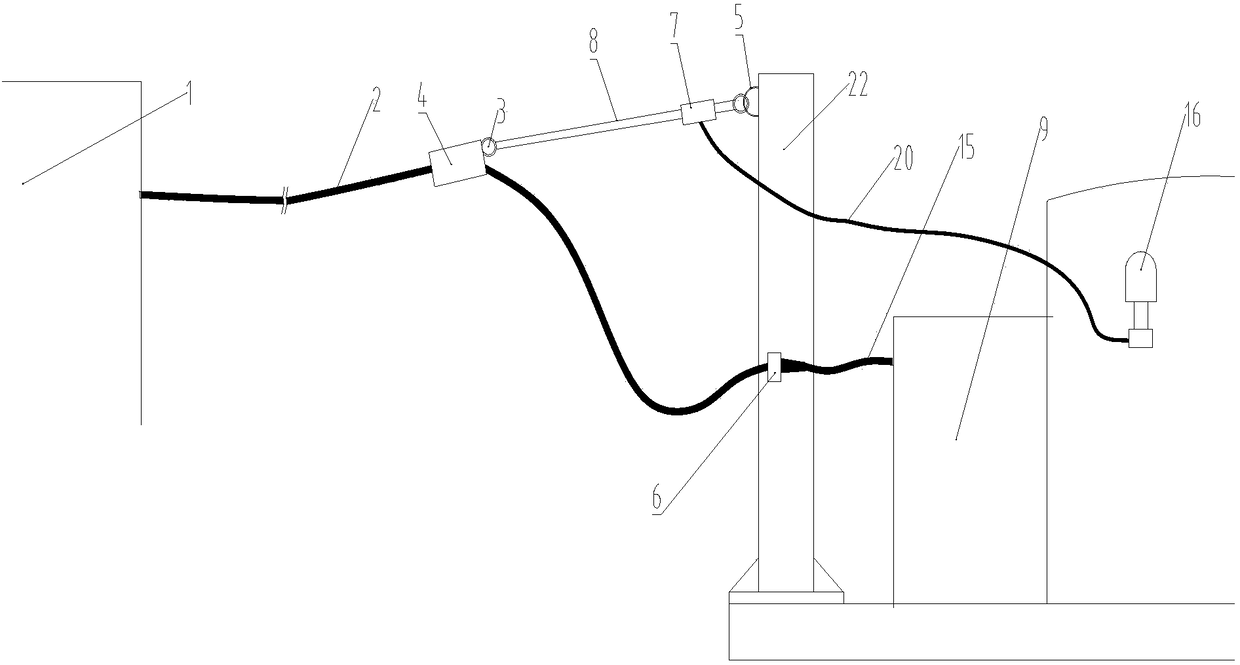

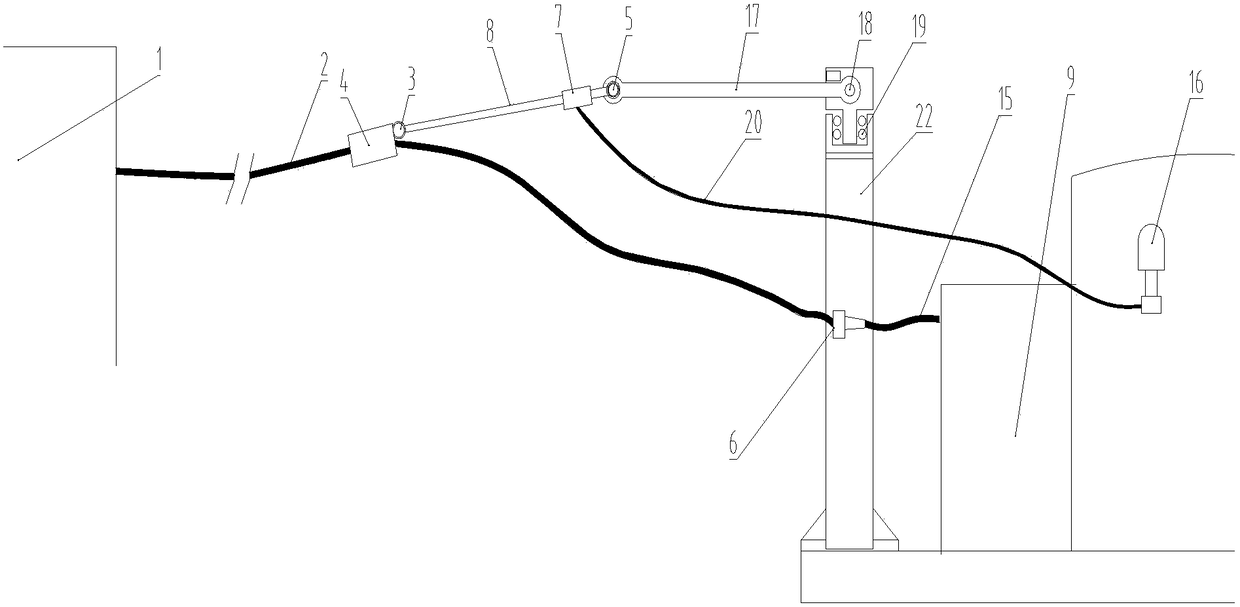

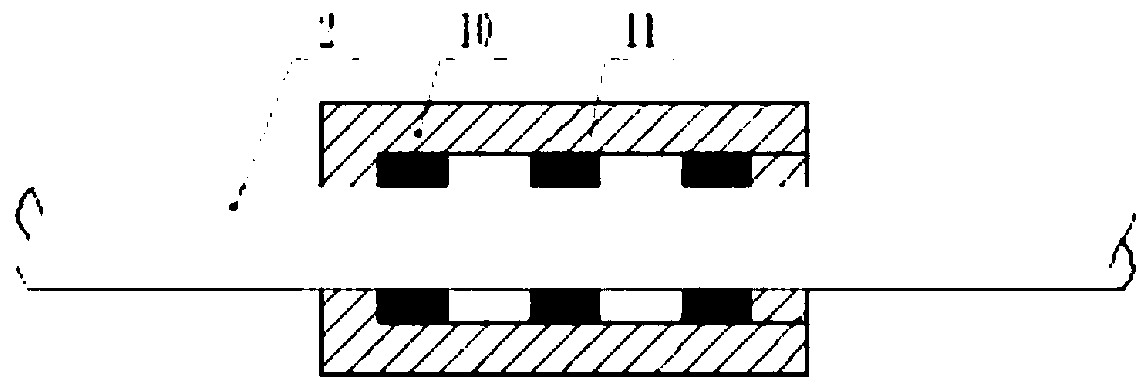

[0019] combined with Figure 1 to Figure 5 .

[0020] The cable connection tension buffer device for engineering machinery includes a power supply end cable 2 and a power consumption end cable 15 electrically connected through a cable plug 6, and the end of the power supply end cable 2 close to the cable plug 6 is provided with a clamping and fixing device 4 for clamping and fixing The device 4 is tension-connected with the electrical equipment 9 through the elastic connecting wire 8 , and the electrical terminal cable 15 electrically connected through the cable plug 6 is electrically connected with the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com