Ventilation damper system and method

A damper and damper technology, applied in the field of ventilation damper systems and methods, capable of solving problems such as generating extra noise and increasing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

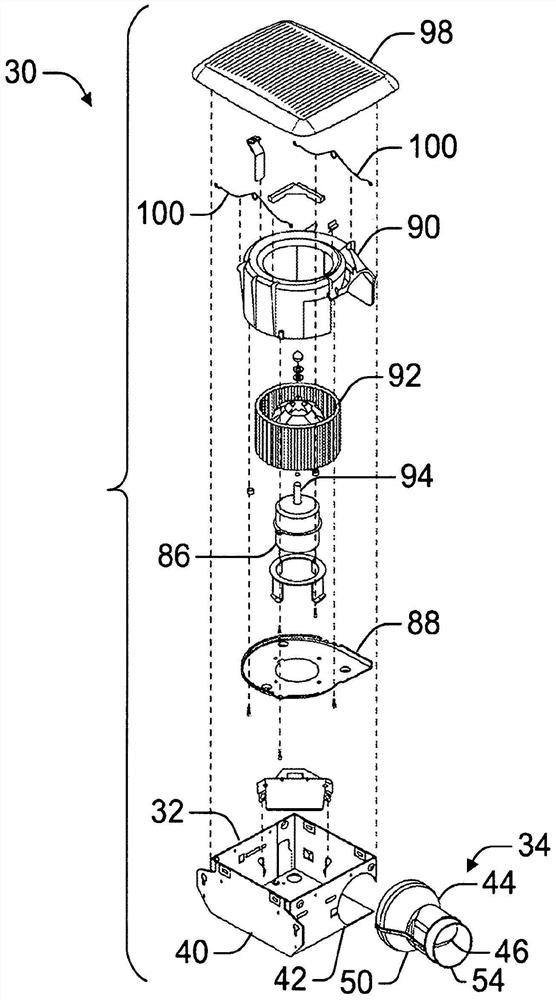

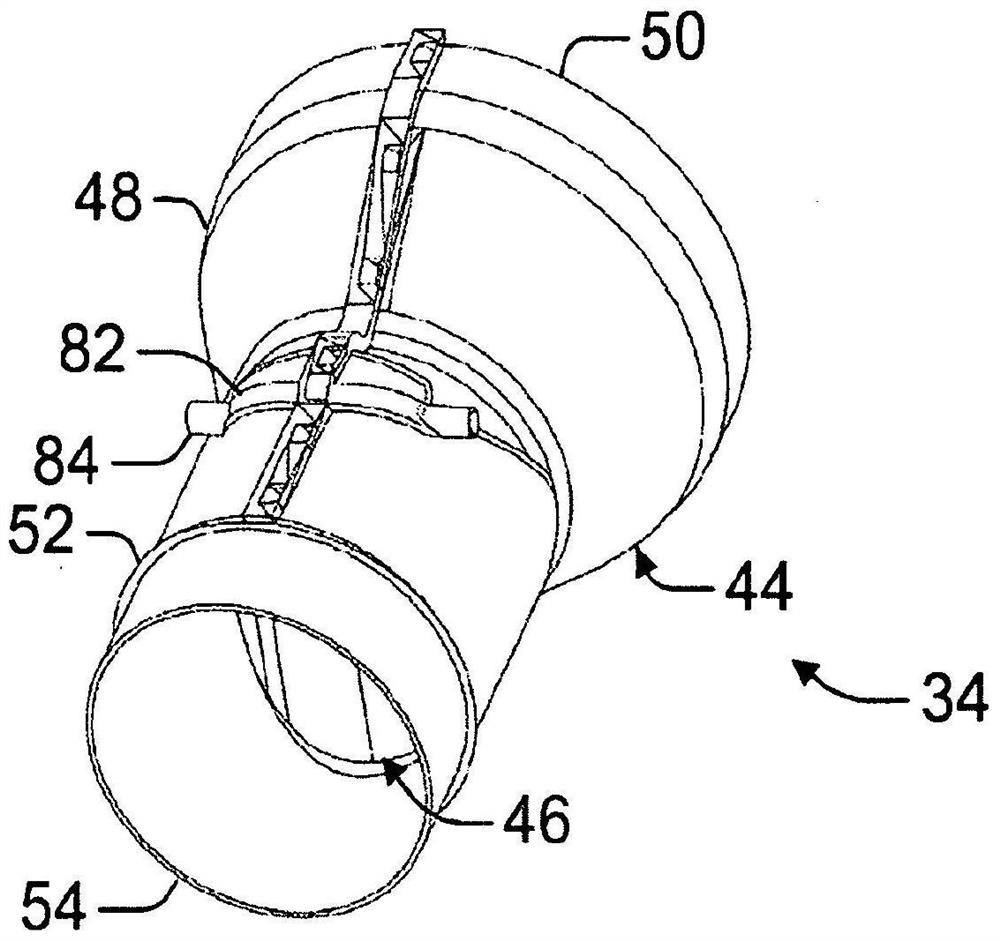

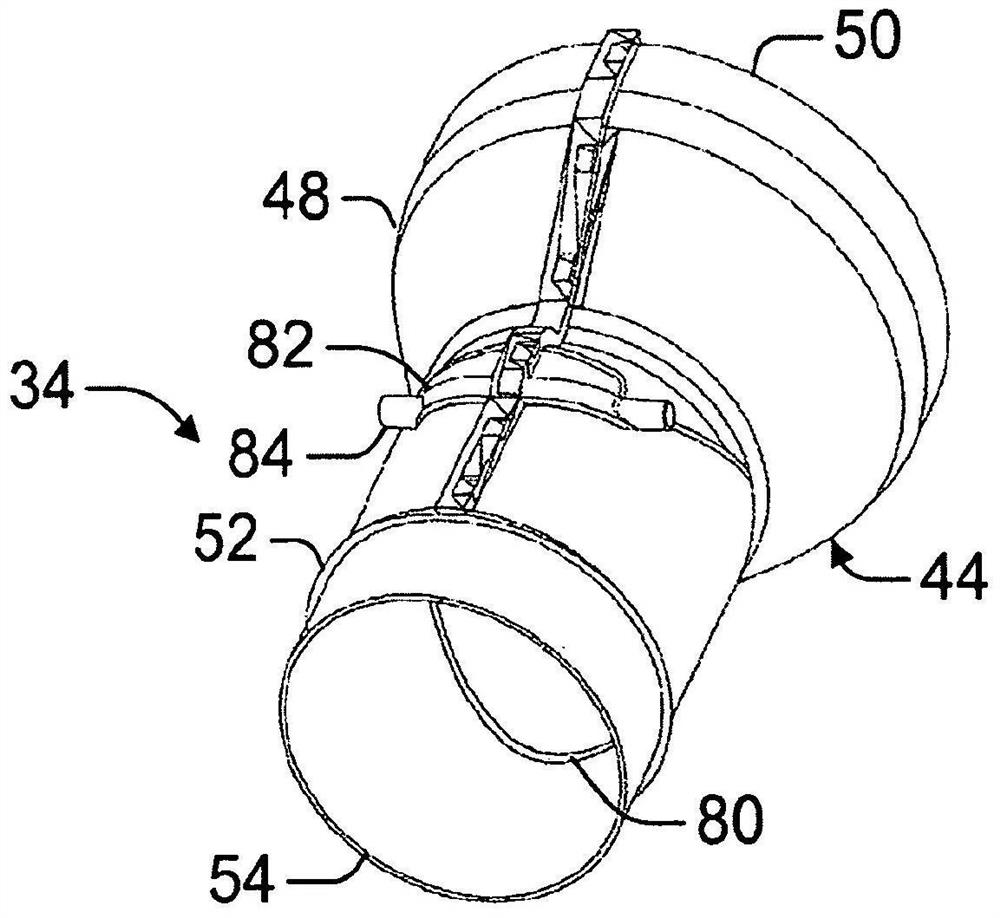

[0047] Such as figure 1 As shown, a ventilation assembly 30 according to one example can include a main housing 32 , a damper assembly 34 and a fan assembly 36 . The main housing 32 can include a housing wall 38 defining an interior space and can include at least an inlet 40 and an outlet 42 . Fan assembly 36 is positionable within the interior space and is operable to generate an input airflow through inlet 40 and an output airflow through outlet 42 . Such as Figure 4A to Figure 4C As shown, the damper assembly 34 can include a main body 44 and a damper door 46 that is rotatable within the main body 44 between at least an open position and a closed position. The body 44 can be positioned at the outlet 42 and is formed in the shape of a tube with an opening for directing the output airflow out of the outlet 42 . In the open position, the damper 46 is rotated to position the damper 46 within the body 44 to allow airflow through the opening. In the closed position, the damp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com