Six-shaft robot capable of moving freely

A six-axis robot and free technology, applied in the field of robotics, can solve the problems of inconvenient robot movement and difficulty in meeting the needs of actual operations, and achieve the effects of rapid lifting, convenient movement, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

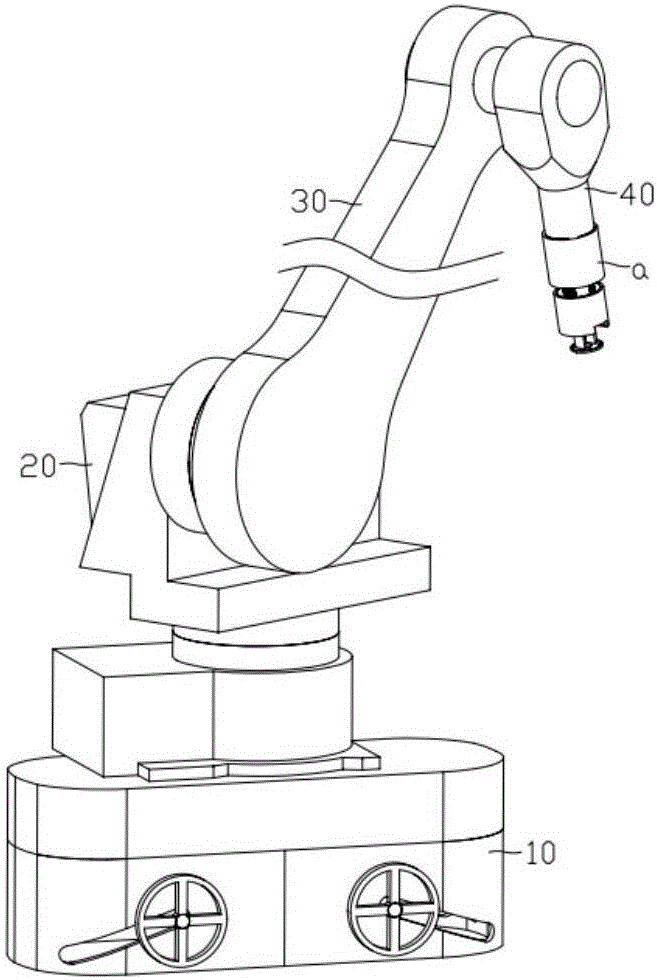

[0048] Such as figure 1 , a freely movable six-axis robot, comprising a base body 10, a waist swivel part 20 pivotally connected to the base body, a big arm 30 pivotally connected to the waist swivel part, a small arm 40 mounted on the big arm, The extension arm a installed on the forearm, the waist swivel part rotates around the base body, and the big arm rotates around the waist swivel part.

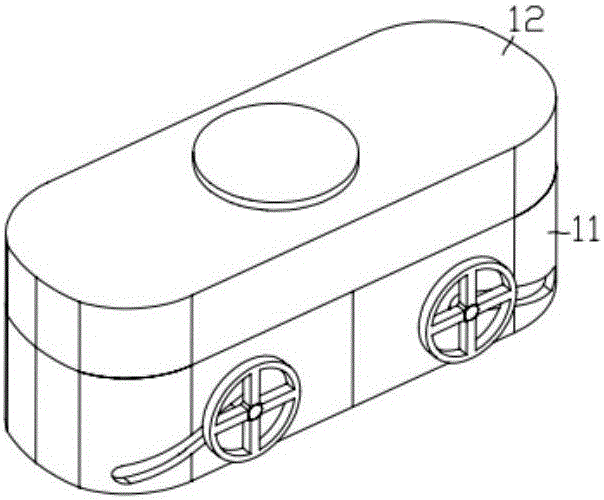

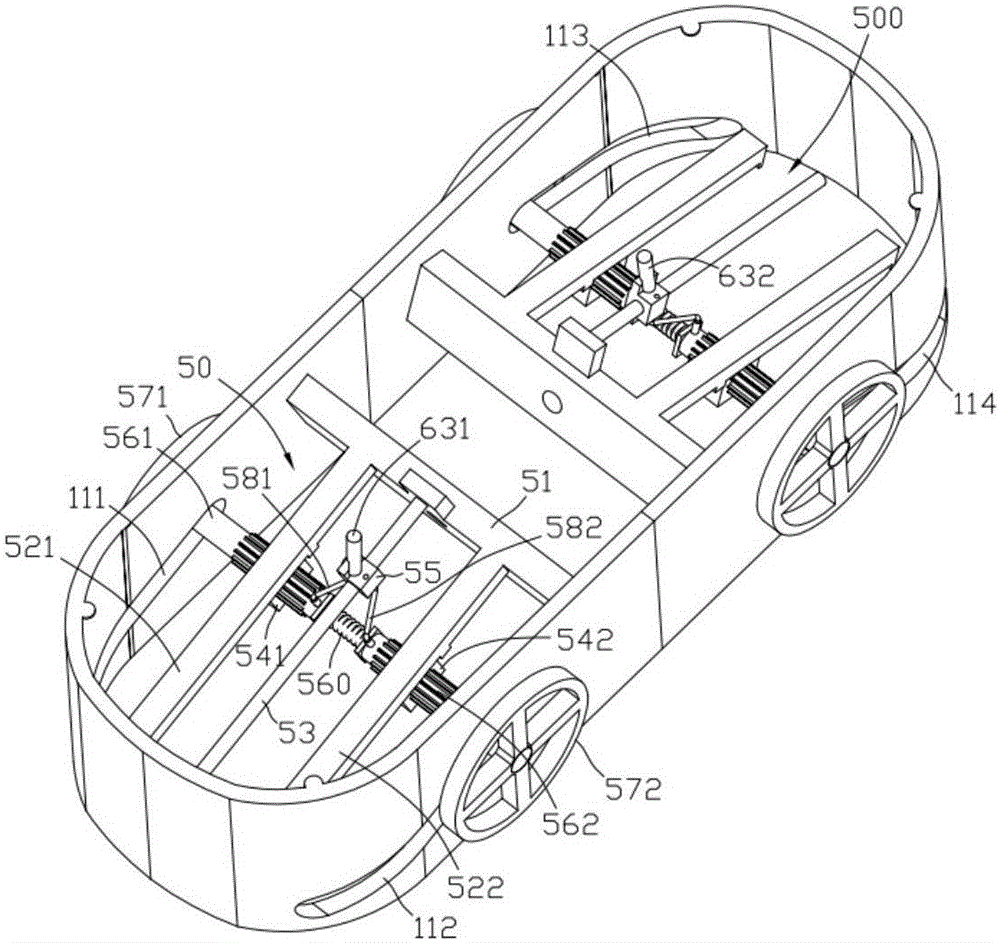

[0049] combine Figure 2 to Figure 6 , the base body includes a hollow base body 11 and a base cover 12 covering the base body; the side walls of the base body are provided with a first pair of left-right symmetrical guide holes and a second pair of left-right symmetrical guide holes , the first pair of guide holes and the second pair of guide holes are elongated and obliquely arranged, and the first pair of guide holes and the second pair of guide holes are arranged symmetrically front and back; a pair of front and back symmetrical roller mechanisms are provided in the base body, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com