Tray type retaining wall structure for weakening mutual influence of subgrade

A technology of mutual influence and retaining wall, which is applied in the direction of basic structure engineering, underwater structures, roads, etc., can solve the problems of affecting the service life of equipment, anti-frost heave performance, and poor durability, so as to achieve simple force, anti-corrosion Good frost heaving performance and high overall bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

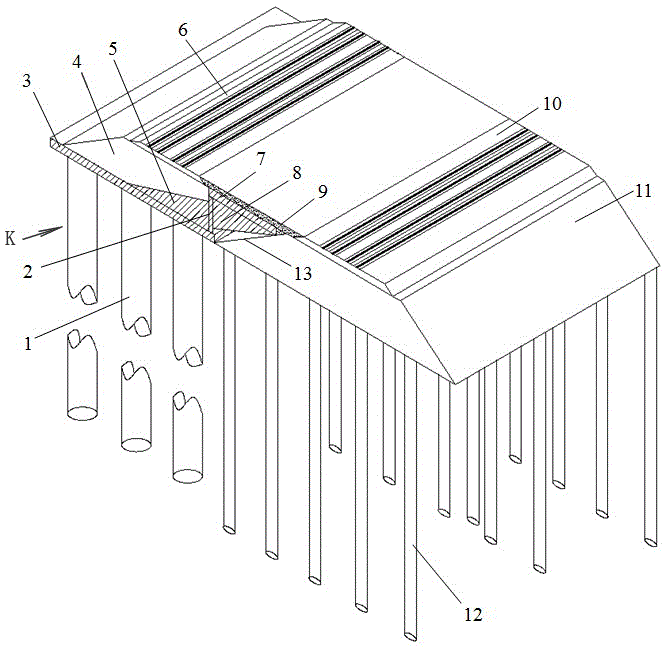

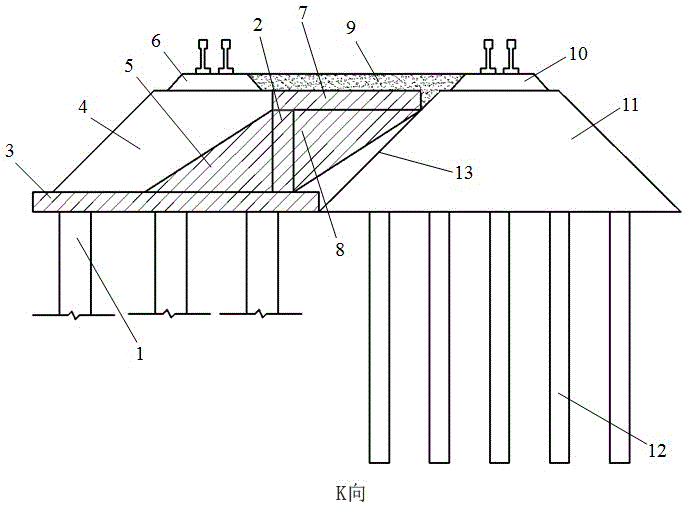

[0024] Such as figure 1 , 2 The shown pallet-type retaining wall structure for weakening the mutual influence between subgrades includes the existing subgrade bed 10, the existing subgrade body 11, the existing subgrade foundation 12 and the existing subgrade slope 13, which along the existing subgrade The bottom surface of one side of the slope 13 in the length direction is provided with a base plate 3, and along the length direction of the lower end of the base plate 3, several row pile foundations 1 are arranged at even intervals, and a retaining wall 2 is arranged at the matching position of the upper end of the base plate 3. The soil wall 2 is composed of a longitudinal baffle and a horizontal baffle 7 vertically overlapped and fixedly connected at one end, the other end of the horizontal baffle 7 is overlapped with the existing roadbed slope 13, and the side of the vertical baffle far away from the horizontal baffle 7 is provided with a newly built The road basic body 4...

Embodiment 2

[0030] Such as figure 1 , 2 The shown pallet-type retaining wall structure for weakening the mutual influence between subgrades includes the existing subgrade bed 10, the existing subgrade body 11, the existing subgrade foundation 12 and the existing subgrade slope 13, which along the existing subgrade The bottom surface of one side of the slope 13 in the length direction is provided with a base plate 3, and along the length direction of the lower end of the base plate 3, several row pile foundations 1 are arranged at even intervals, and a retaining wall 2 is arranged at the matching position of the upper end of the base plate 3. The soil wall 2 is composed of a longitudinal baffle and a horizontal baffle 7 vertically overlapped and fixedly connected at one end, the other end of the horizontal baffle 7 is overlapped with the existing roadbed slope 13, and the side of the vertical baffle far away from the horizontal baffle 7 is provided with a newly built The road basic body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com