A nail bolt

A bolt and nail-shooting technology, applied in bolts, screws, threaded fasteners, etc., can solve the problems affecting the physical and mental health of workers, the falling of concrete dust, and the high labor intensity. effect of income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

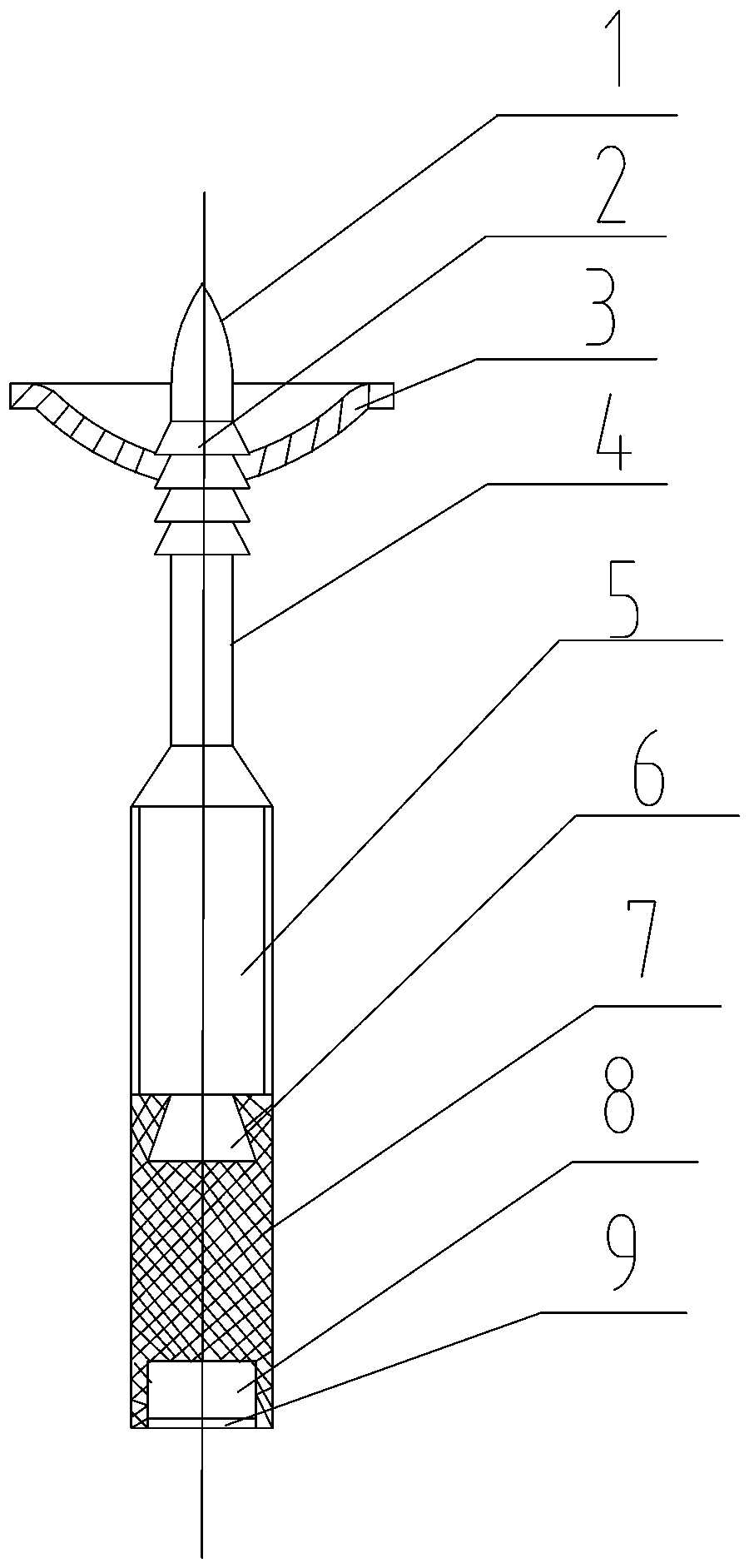

[0013] Such as figure 1 As shown, a nail bolt of the present invention includes a nail bolt divided into two sections along its length direction, one section is a long column 4, and the end of the long column 4 is provided with a tip 1, and the other section is a threaded column 5. The threaded column is divided into M6, M8, M10, M12, M16, and can be provided with various specifications and sizes according to the load size. The diameter of the tip 1 at the end of the long column 4 is divided into Ф3.7, Ф4.5, Ф5.2 or Ф5. 5. It is characterized in that the anti-recession pattern 2 is evenly distributed on the tip 1 of the long column, and a buffer washer 3 is provided on the retreating pattern 2, and the buffer washer 3 is in interference fit with the retreating pattern 2, and the The buffer washer 3 is a circular arched structure. The buffer washer adopts a circular archin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com