A Lubricating Oil Purification and Circulation Device with High Precision

A technology for purifying circulation and lubricating oil, which is applied in the direction of engine lubrication, lubricating parts, engine components, etc., which can solve the problems of increased power consumption of equipment, achieve weight reduction, simple and low structure, and prevent the short circuit of the driving coil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

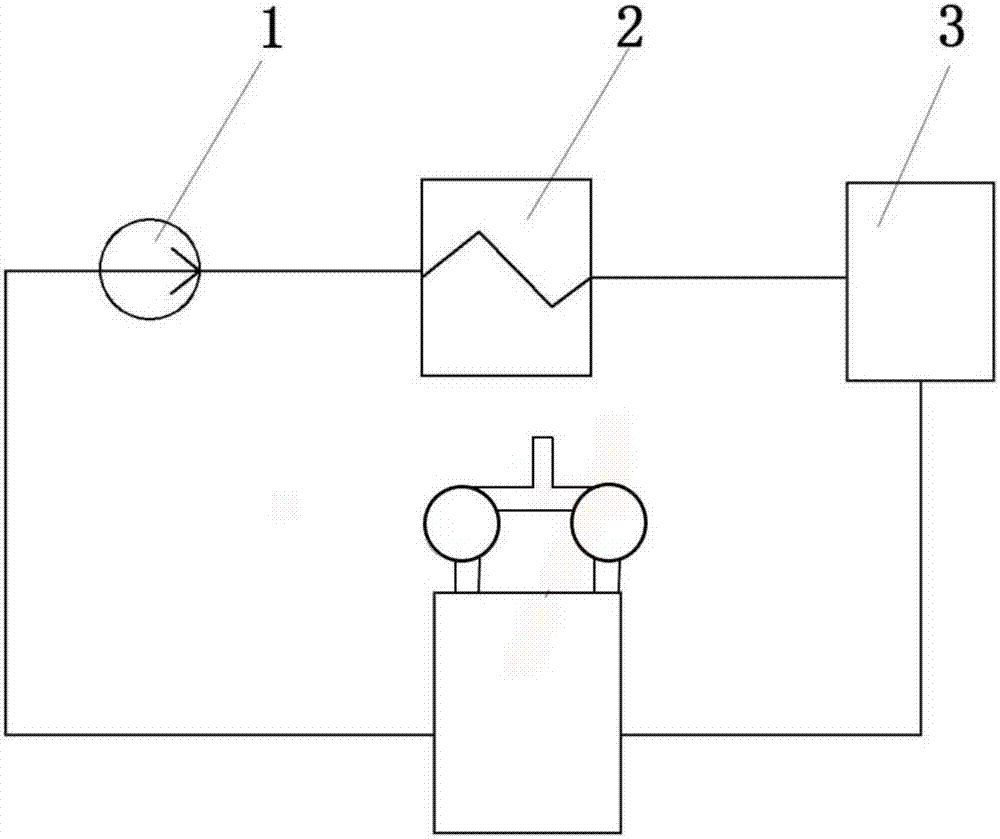

[0031] Such as figure 1 A lubricating oil purification and circulation device with high precision is shown, which includes a giant magnetostrictive pump 1, an oil cooler 2, a centrifugal oil separator 3 and an oil tank 4 connected in sequence. The telescopic pump 1 is sent to the oil cooler 2, and after cooling to a predetermined temperature, it enters the centrifugal oil separator 3 for oil-water separation, and then returns to the oil tank 4. The cooling source of the oil cooler 2 is industrial cooling water; the oil tank is provided with two fume exhaust fans for draining the oil fume accumulated in the oil tank 4 and keeping the oil tank 4 in a slightly negative pressure state. The two fume exhaust fans are one in operation and one in standby, and an outlet switching three-way valve is arranged at the outlets of the two. An inlet valve is provided at the inlets of the two oil fume exhaust fans. The cooling source of the oil cooler 2 is industrial cooling water; the oil t...

Embodiment 2

[0042] Such as figure 1 A lubricating oil purification and circulation device with high precision is shown, which includes a giant magnetostrictive pump 1, an oil cooler 2, a centrifugal oil separator 3 and an oil tank 4 connected in sequence. The telescopic pump 1 is sent to the oil cooler 2, and after cooling to a predetermined temperature, it enters the centrifugal oil separator 3 for oil-water separation, and then returns to the oil tank 4. The cooling source of the oil cooler 2 is industrial cooling water; the oil tank is provided with two fume exhaust fans for draining the oil fume accumulated in the oil tank 4 and keeping the oil tank 4 in a slightly negative pressure state. The two fume exhaust fans are one in operation and one in standby, and an outlet switching three-way valve is arranged at the outlets of the two. An inlet valve is provided at the inlets of the two oil fume exhaust fans.

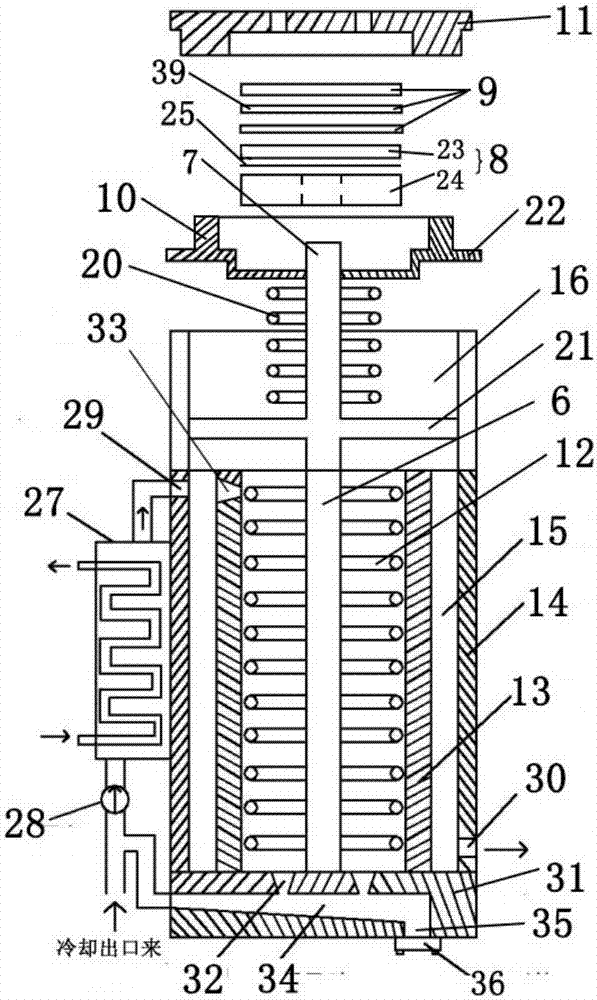

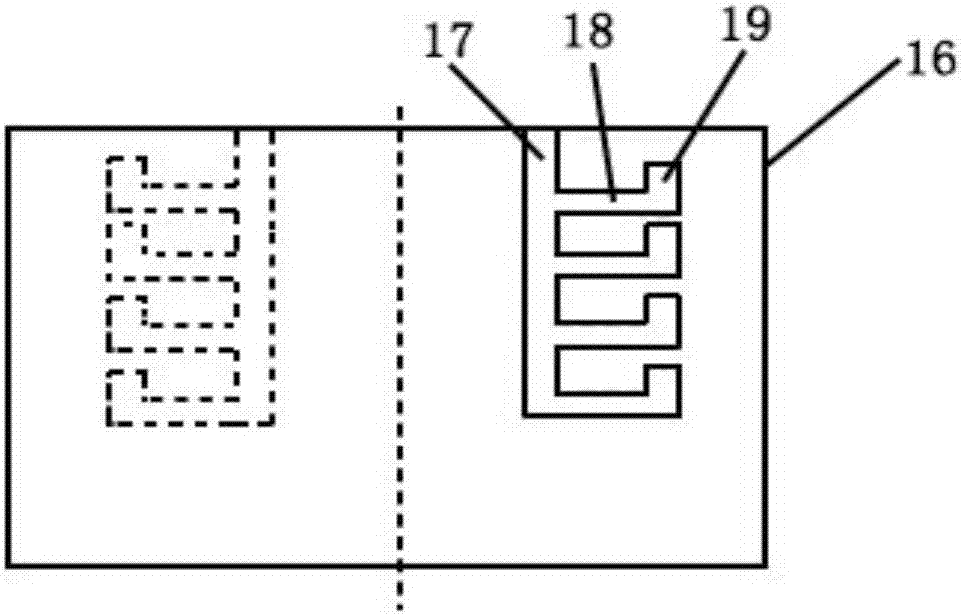

[0043] Such as figure 2 As shown, the giant magnetostrictive pump 1 is in...

Embodiment 3

[0054] Such as figure 1 A lubricating oil purification and circulation device with high precision is shown, which includes a giant magnetostrictive pump 1, an oil cooler 2, a centrifugal oil separator 3 and an oil tank 4 connected in sequence. The telescopic pump 1 is sent to the oil cooler 2, and after cooling to a predetermined temperature, it enters the centrifugal oil separator 3 for oil-water separation, and then returns to the oil tank 4. The cooling source of the oil cooler 2 is industrial cooling water; the oil tank is provided with two fume exhaust fans for draining the oil fume accumulated in the oil tank 4 and keeping the oil tank 4 in a slightly negative pressure state. The two fume exhaust fans are one in operation and one in standby, and an outlet switching three-way valve is arranged at the outlets of the two. An inlet valve is provided at the inlets of the two oil fume exhaust fans.

[0055] Such as figure 2 As shown, the giant magnetostrictive pump 1 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com