Reciprocating pump

A technology of reciprocating pump and reciprocating mechanism, applied in the field of reciprocating pump, can solve the problems of large occupied space, large impact pulsation, complex structure, etc., and achieve the effect of less device parts, small impact pulsation, stable and reliable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

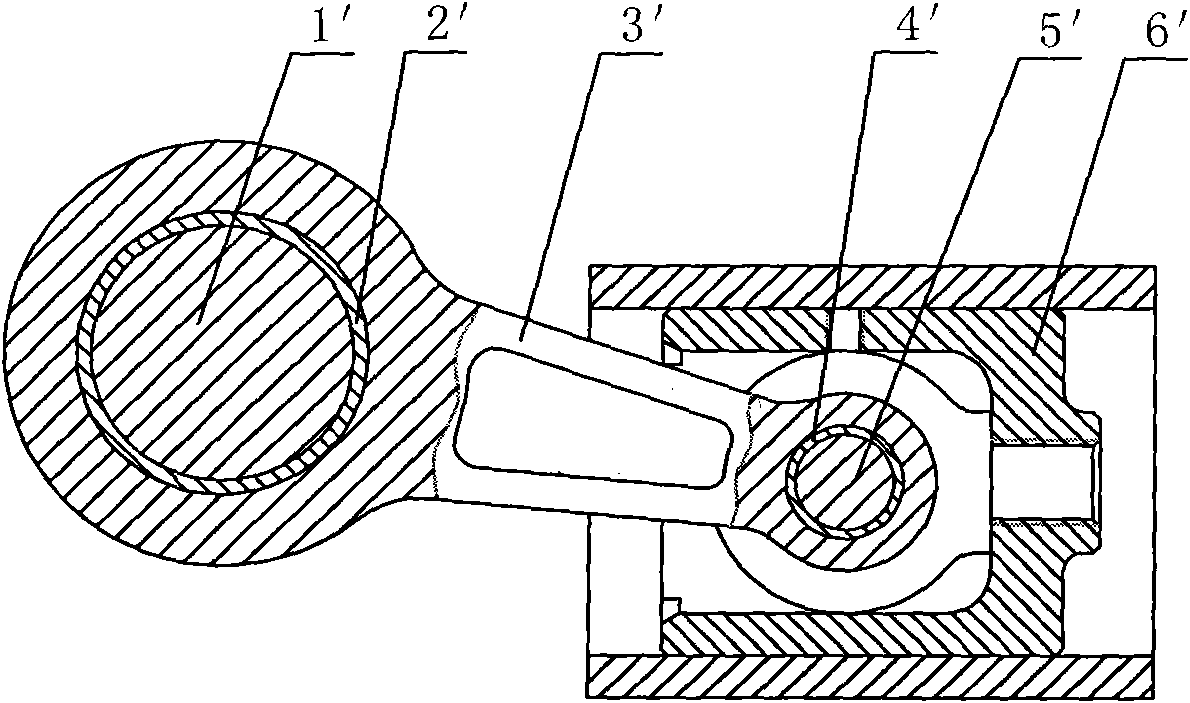

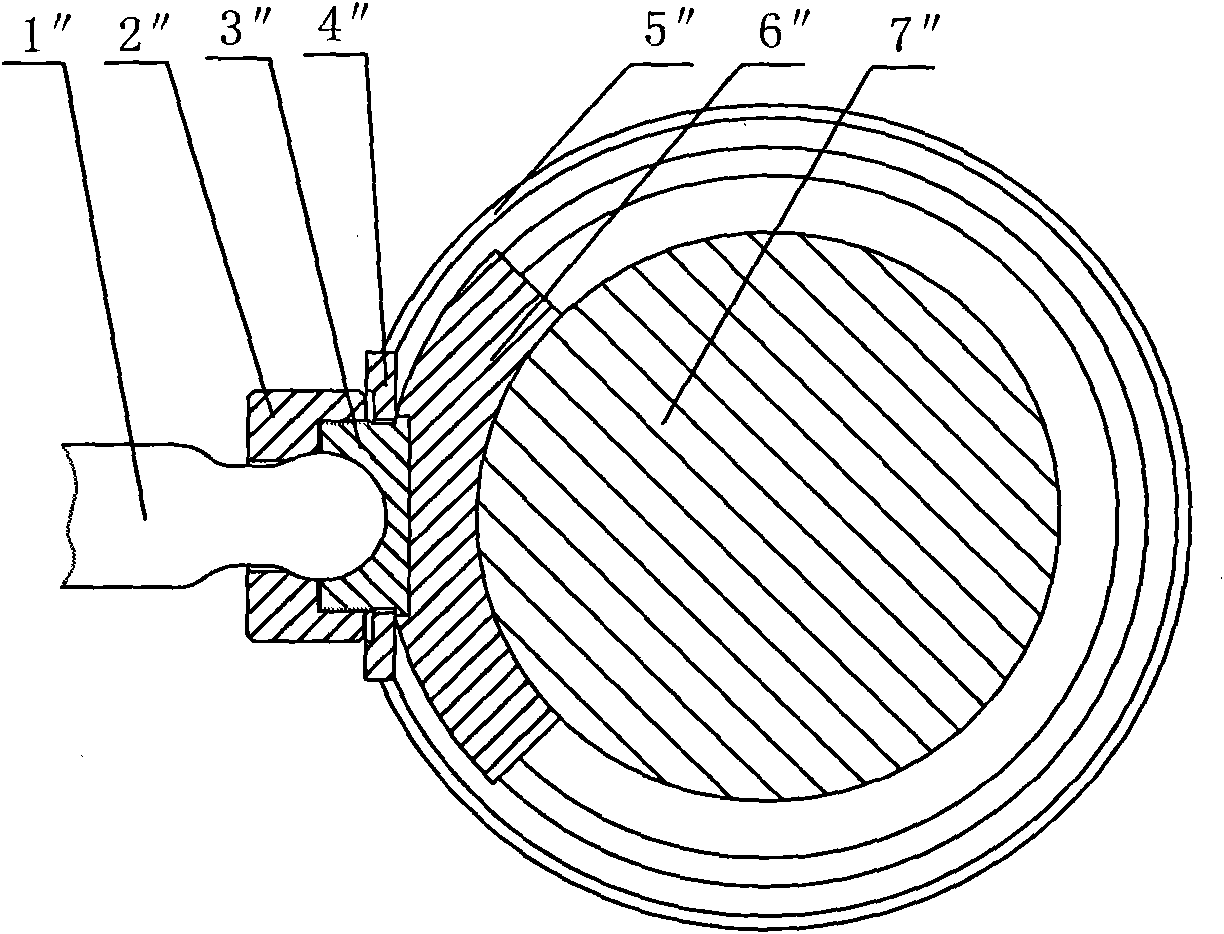

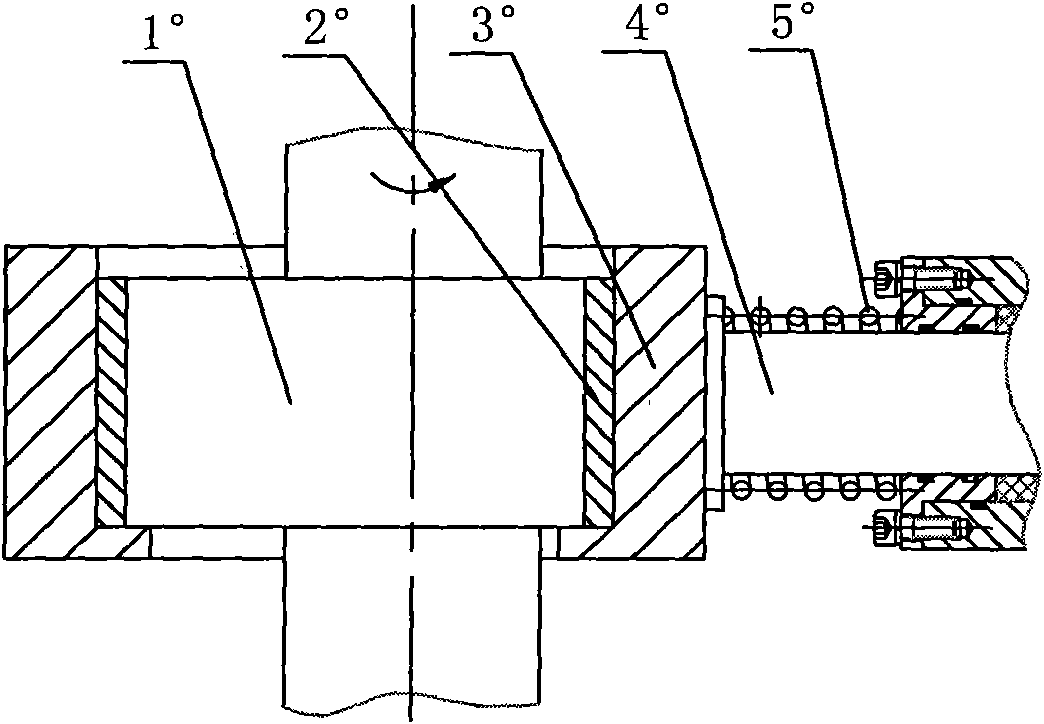

[0015] refer to Figure 4-6 , a reciprocating pump, composed of a transmission end structure and a hydraulic end structure, the transmission end structure includes a fuselage 8, a reciprocating mechanism, the reciprocating mechanism includes a connecting rod 1, a plunger 4, and a crankshaft 2, and the crankshaft 2 is provided with There is a supporting bearing 5, and a connecting rod bearing 3 is installed between the connecting rod 1 and the crank throw 6 of the crankshaft 2, and the connecting rod bearing 3 is eccentric relative to the supporting bearing 5, and the inner hole of the connecting rod 1 is formed from the upper and lower Two semicircular arcs 11 are connected with the middle straight section 12, the connecting rod bearing 3 is in contact with the straight section 12 of the inner hole of the connecting rod 1, and the connecting rod head 13 of the connecting rod 1 is connected with the plunger 4 .

[0016] A retaining ring 7 is arranged below the connecting rod b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com