High-power truncated microwave output window

A high-power, output window technology, applied in the field of high-power microwave transmission and radiation, high-power microwave, can solve the problems of large microwave output window size, unable to meet the application requirements of high power capacity and compactness at the same time, and achieve high power The effect of capacity and high efficiency microwave transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

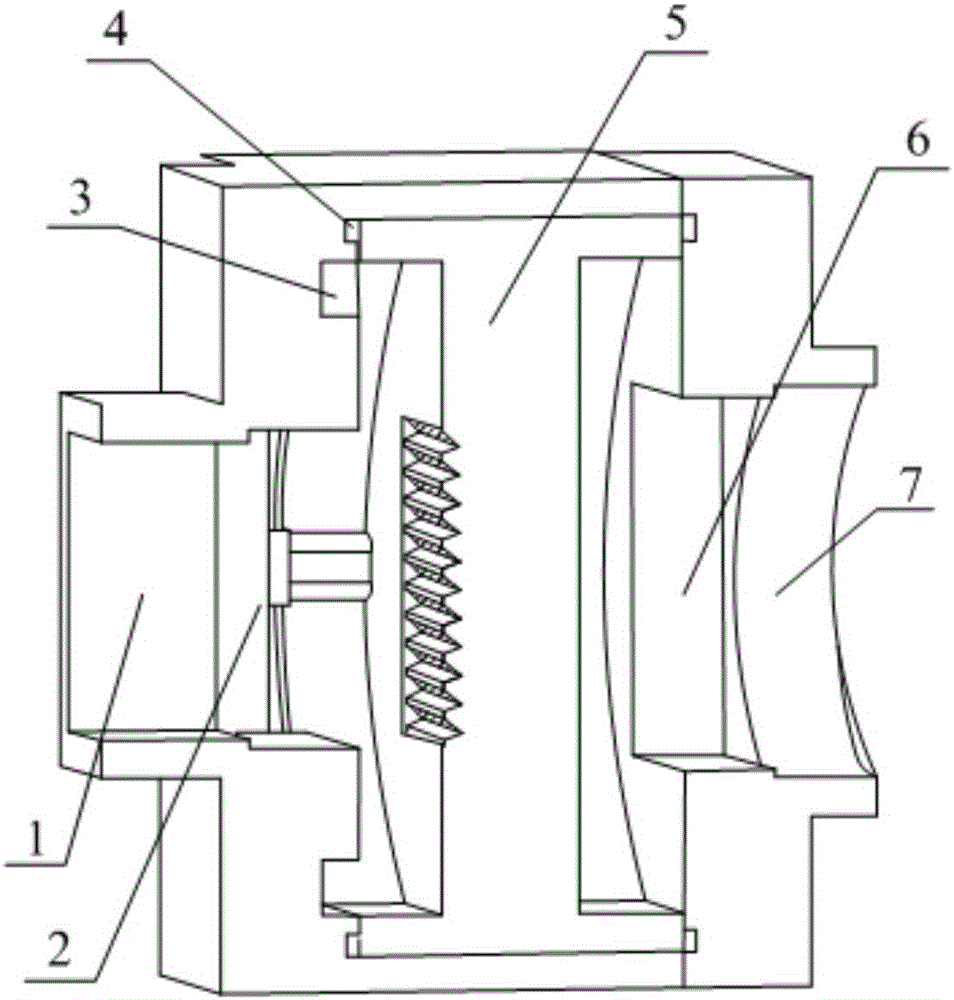

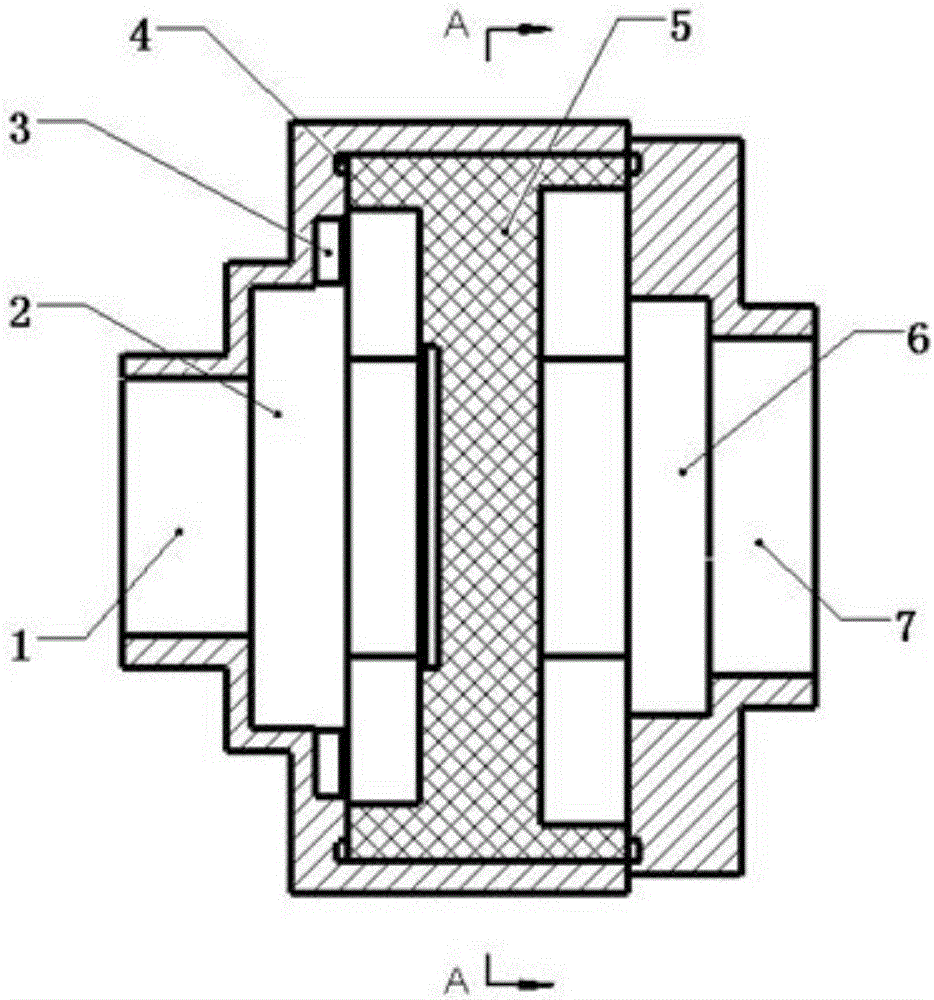

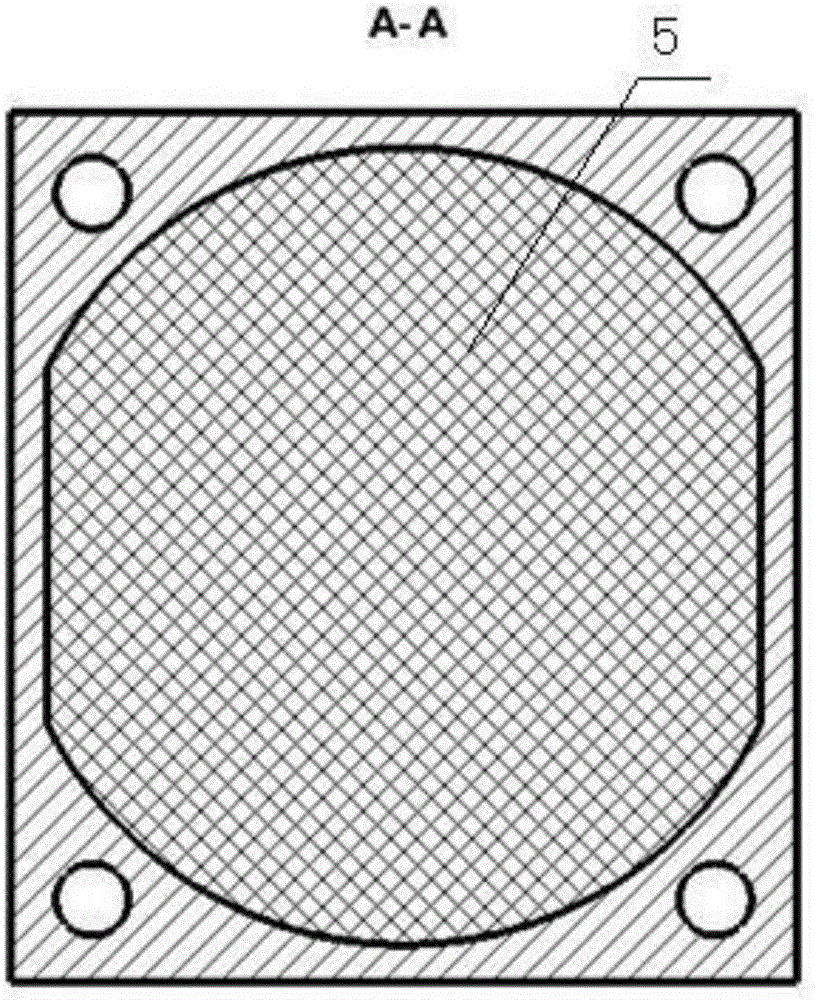

[0023] Such as Figure 1-3 As shown, the high-power truncated microwave output window is mainly composed of input square waveguide 1, input matching transition waveguide 2, field suppression ring 3, sealing groove 4, I-shaped dielectric window 5, output matching transition waveguide 6, and output circular waveguide The input square waveguide 1 is connected to the I-shaped dielectric window 5 through the input matching transition waveguide 2, and then connected to the output round waveguide 7 by the output matching transition waveguide 6, and all structures are coaxial.

[0024] The field suppression ring 3 structure is adopted on the input surface of the I-shaped dielectric window 5, which can effectively improve the power capacity. By adjusting the size parameters of the input matching transition waveguide 2, the field suppression ring 3, the I-shaped dielectric window 5 and the output matching transition waveguide 6, high-efficiency microwave transmission from the input squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com