Plate inserted coaxial micro-wave mode converter

A mode conversion, plug-in technology, applied in waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of low power capacity, complex structure, difficult processing, etc., and achieve the effect of high power capacity, high power, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

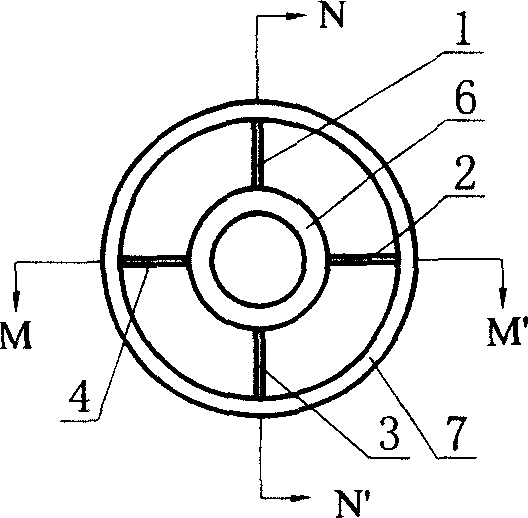

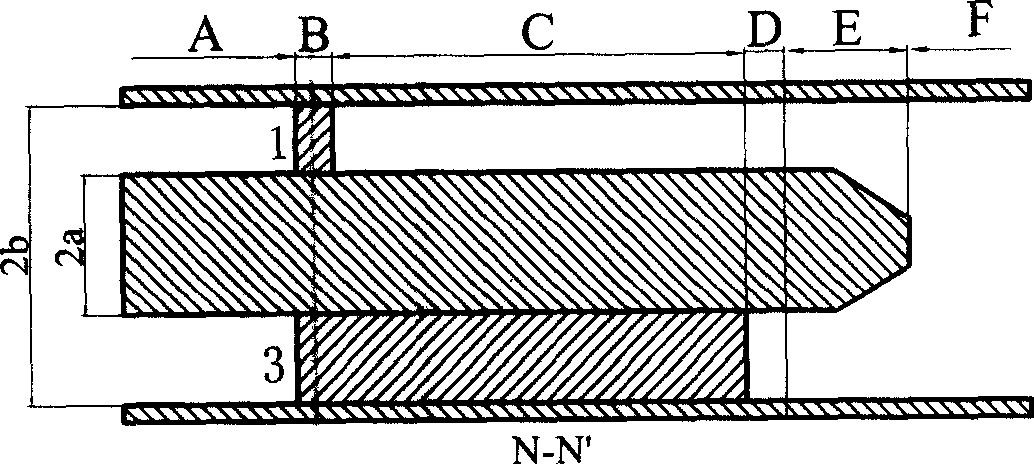

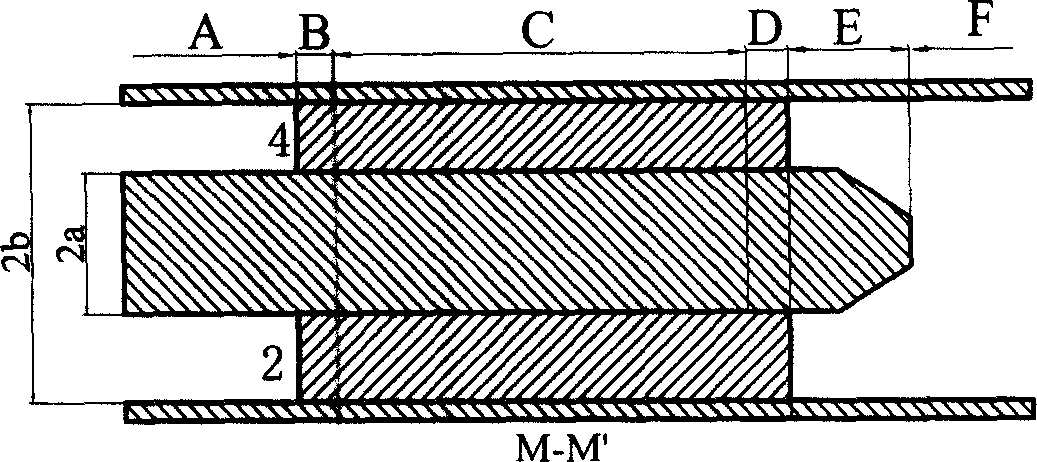

Image

Examples

Embodiment 2

[0035] Figure 7 It is shown that the only difference between the structure of the mode converter in this example and the first embodiment is that the front end of the inner conductor 6 of the coaxial waveguide is tapered with a certain slope, and the rest of the structure is the same as that of the first embodiment. The structure is a circular waveguide TM 01 - Coaxial TEM transition section, so that the mode converter in this example can realize the circular waveguideTM 01 Mode-coaxial TEM mode transformation.

[0036] The specific design dimensions for the microwave mode conversion of 3.8 GHz in this embodiment are given below:

[0037] Circular waveguide TM with microwave source output frequency of 3.8GHz 01 mode, the waveguide radius is b=4.5cm. The front end of the inner conductor of the mode converter in embodiment 1 is designed as Figure 5 The shape of the cone shown, other parameters and dimensions are the same as the specific design in the first embodiment, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com