Self-liquid-preparation concentration-adjustable anti-freezing dust-suppression spraying system of large rock dumping machine

A technology of spraying system and rock removal machine, which is applied in the directions of dust prevention, mixer accessories, mixers, etc., can solve the problems of inability to accurately control the excess or shortage of the solution, low efficiency, and inability to adjust the concentration, and achieves a high degree of automation, The effect of improving concentration accuracy and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the technical solutions described in the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto, and the scope of protection of the present invention is not limited to the examples. represented range.

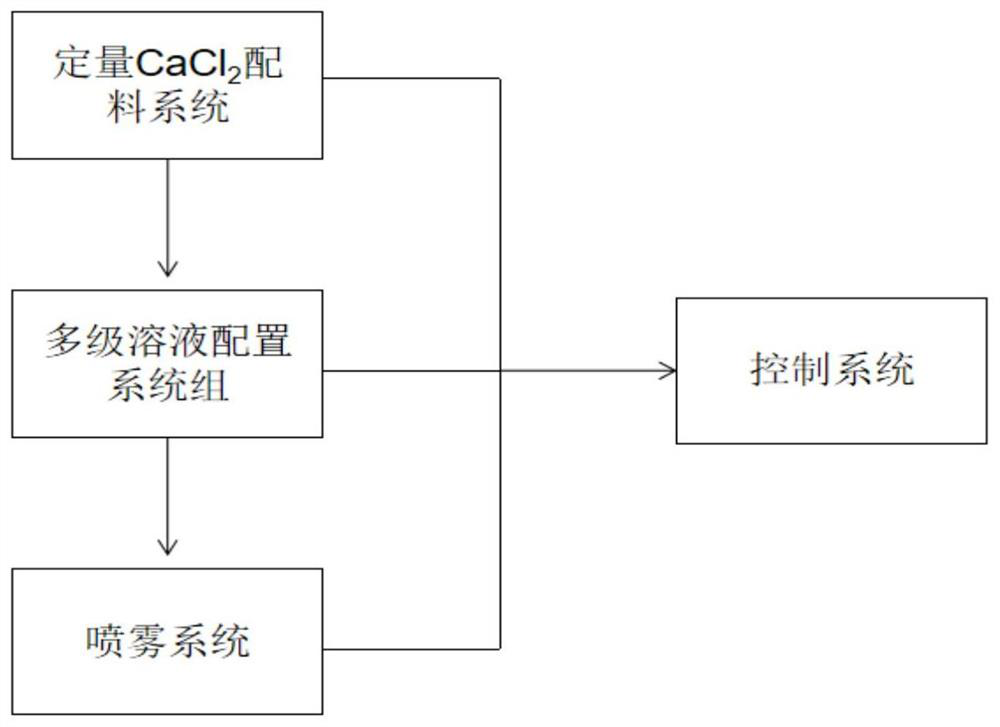

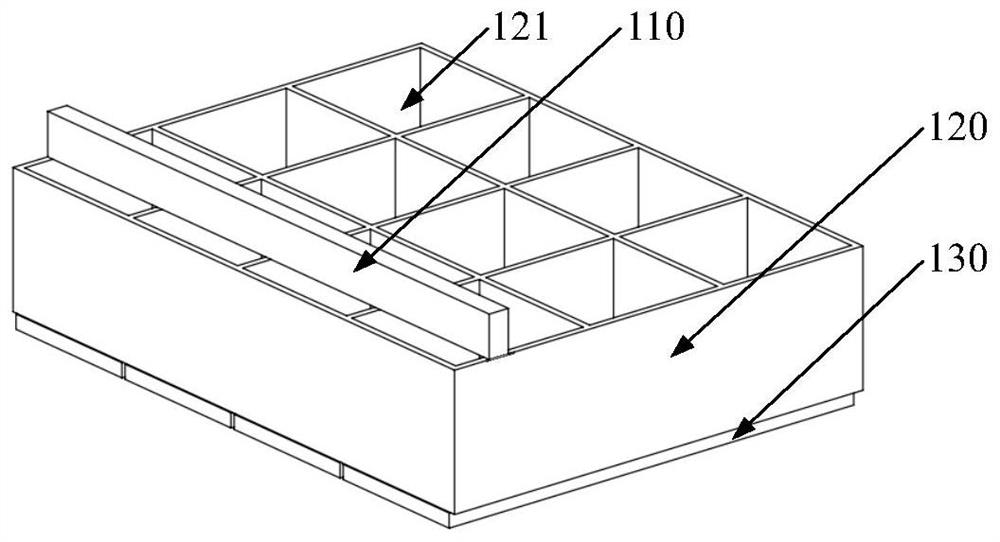

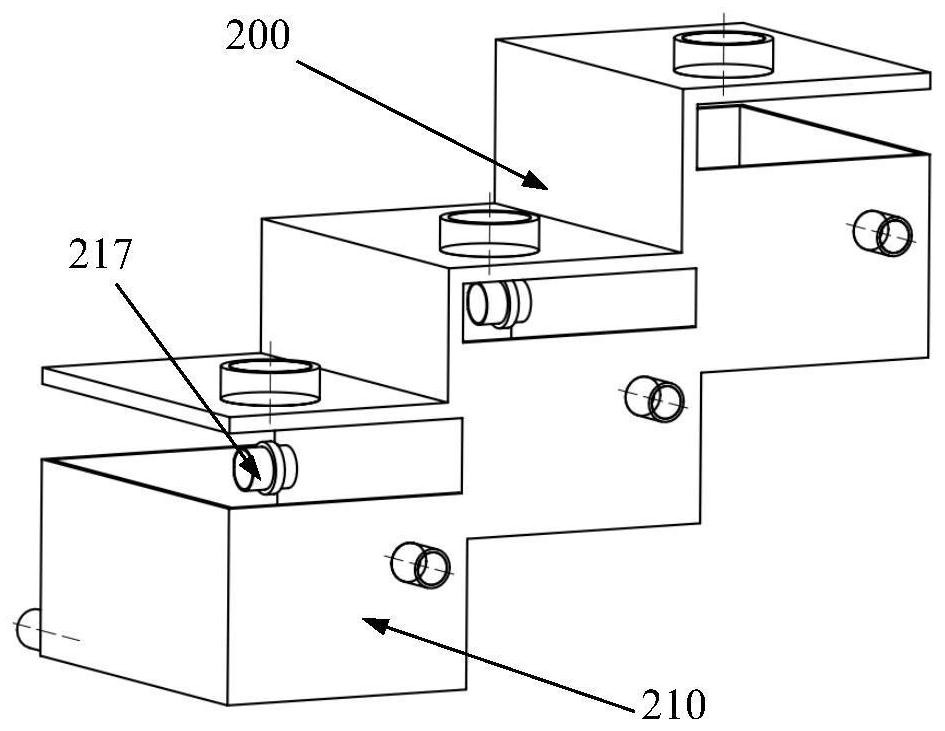

[0023] like Figure 1-5 As shown, a large-scale rock excavator self-preparing liquid adjustable concentration antifreeze and dust suppression spray system, including quantitative CaCl 2 Batching system, multi-stage solution configuration system group, spray system, control system; the quantitative CaCl 2 The batching system is connected with the multi-stage solution configuration system group, and the quantitative CaCl 2 The batching system is installed on the top of each single-stage solution configuration system of the multi-stage solution configuration system group, and is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com