Novel auxiliary winding of transformer

A technology of auxiliary winding and transformer, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of unbalanced ampere-turn of main winding, occupying space of main winding, affecting the layout of main winding, etc. Outgoing line and insulation distance, the effect of enhancing the ability to resist short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

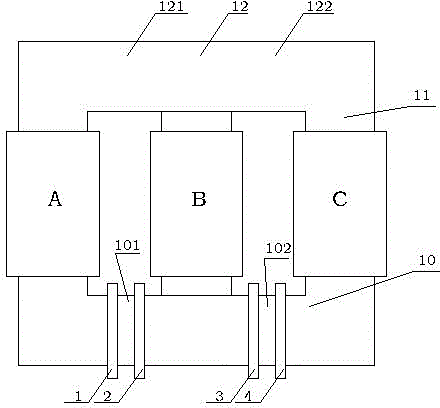

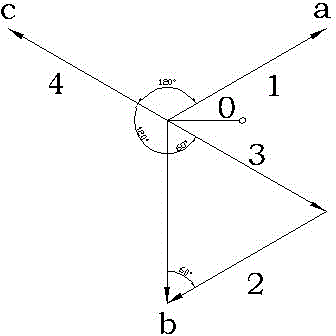

[0016] Embodiment one, see figure 1 , 2 , the transformer of the present invention is shown in the figure, see figure 1 , A, B, and C in the figure are the three-phase main windings of the transformer, and the three-phase main windings A, B, and C are respectively arranged on the iron core column 11, and the upper and lower ends of the iron core column 11 are the iron yoke 12 and the iron yoke 10 , the transformer of the present invention also contains an auxiliary winding. The inventive point of the present invention is that: the auxiliary winding is arranged on the iron yoke, in this embodiment, it is arranged on the iron yoke 10, and the auxiliary winding includes four single-phase auxiliary windings 1, 2, 3, 4, Its turns ratio is: 1:1:1:1, and it is divided into two groups: single-phase winding 1, 2 and single-phase winding 3, 4. The iron core column 11 located in the middle divides the iron yoke 10 into a left iron yoke 101 and a right iron yoke 102, and there are two ...

Embodiment 2

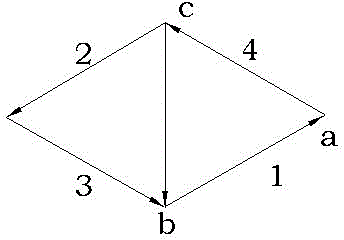

[0018] Embodiment two, see image 3 , and the difference from the previous embodiment is that another wiring method of the auxiliary winding is shown in the figure, that is, a delta connection method is used: the three-phase windings a, b, and c are connected end to end to form a closed form, and the b phase is also It is formed by the single-phase auxiliary windings 2 and 3 connected in series and reversed.

Embodiment 3

[0019] Embodiment three, see Figure 4 , 5 , another embodiment is shown in the figure, the difference from the first embodiment is that the auxiliary winding in the present invention is composed of 8 coils 1, 2, 3, 4, 5, 6, 7, 8, That is, the four single-phase auxiliary windings in the present invention are all composed of two coils (1, 2), (3, 4), (5, 6), (7, 8). The 8 coils in this embodiment are equally divided into two groups (1, 2, 3, 4), (5, 6, 7, 8) and are arranged on the left iron yokes 101, 121 and the right iron yokes 102, 122 respectively. ,Such as Figure 5 As shown: the two coils 1 and 2 on the left iron yoke 121 are connected in series to form phase a, the two coils 7 and 8 on the right iron yoke 122 are connected in series to form phase c, and the coils in the remaining two groups 3 and coil 4 are set on the left iron yoke 101 and connected in series first, coils 5 and 6 are located on the right iron yoke 102 and connected in series first, and then the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com