Electrical cabinet capable of withstanding moderate impact force

A technology of impact force and electrical cabinets, applied in the field of electrical cabinets, can solve the problems of increasing the wall thickness of reinforcing ribs, increasing the thickness of the wall, and failing to meet the anti-collision requirements, achieving good practical effects and increasing the effect of anti-collision ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

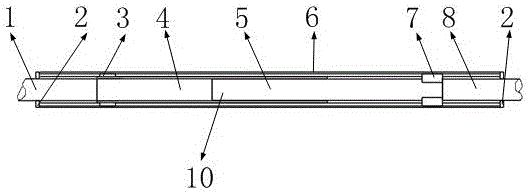

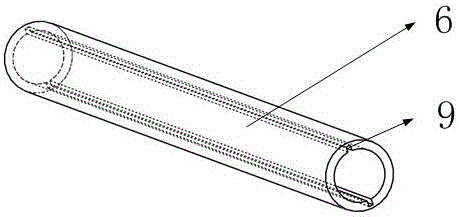

[0020] Such as Image 6 As shown, it includes a support plate 12, a cabinet body 13, a component mounting plate 14, a mounting plate strut 15, a positioning rod 16, a ball hinge 17, and a ventilation structure 18, among which such as Image 6 As shown, the cabinet body 13 is a cuboid shell and has six sides such as upper, lower, left, right, front and rear. The ventilation structure 18 is connected by four flat plates in sequence and forms an angle of 90 degrees between two adjacent plates. The four corners of the ventilation structure 18 are respectively connected to the four corners inside the cabinet body 13 through four support plates 12; support plate grooves 11 are opened on the support plates 12; Three ball hinges 17 are installed, and the ball hinges 17 are located in the middle of the front and back surfaces, and each ball hinge 17 is respectively equipped with a component mounting plate 14 through the mounting plate strut 15, such as Figure 7 As shown, between the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap