Multi-furnace and multi-liquid-rise-pipe molten aluminum mold filling method structure for sand mold low-pressure cast gas-tight thin-walled shells

A technology of low-pressure casting and thin-walled shells, which is applied in the field of metal materials or metallurgy, can solve problems affecting product quality, turbulent flow, and affecting rising liquid pouring, etc., and achieves the effects of convenient installation, low cost, and no cold insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

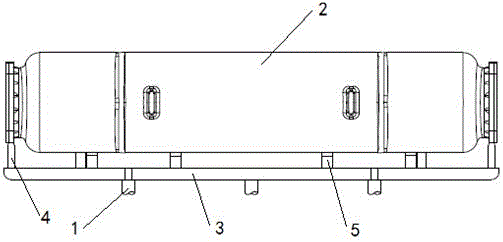

[0012] Such as figure 1 The structure of the sand-type low-pressure casting airtight thin-wall shell with multiple furnaces and multiple risers for aluminum liquid filling includes a riser 1 and a thin-walled aluminum alloy casting 2, and the horizontal direction above the riser 1 is A liquid flow tank 3 is provided, and the two ends of the liquid flow groove 3 and the positions that can be set are fixedly connected to the thin-walled aluminum alloy casting 2 through the pouring port 4, and the number of the liquid riser 1 and the pouring port 4 is at least 2 One, the flow tank 3 is a horizontal sand core flow tank, and the inside is painted with paint, and a column sprue 5 is also provided between the flow tank 3 and the thin-walled aluminum alloy casting 2 .

[0013] The above descriptions are preferred embodiments of the present invention, and should not be used to limit the scope of rights of the present invention. It should be pointed out that for those skilled in the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com