Grass feeder for bundling machine

A baler and grass-shunting technology, which is applied in the field of baler grass feeders, can solve the problems of increasing equipment manufacturing costs and increasing the volume of straw baling equipment, and achieve the goals of improving work efficiency, small space, and reducing collection and compression Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the following will be specifically described in conjunction with the accompanying drawings and embodiments.

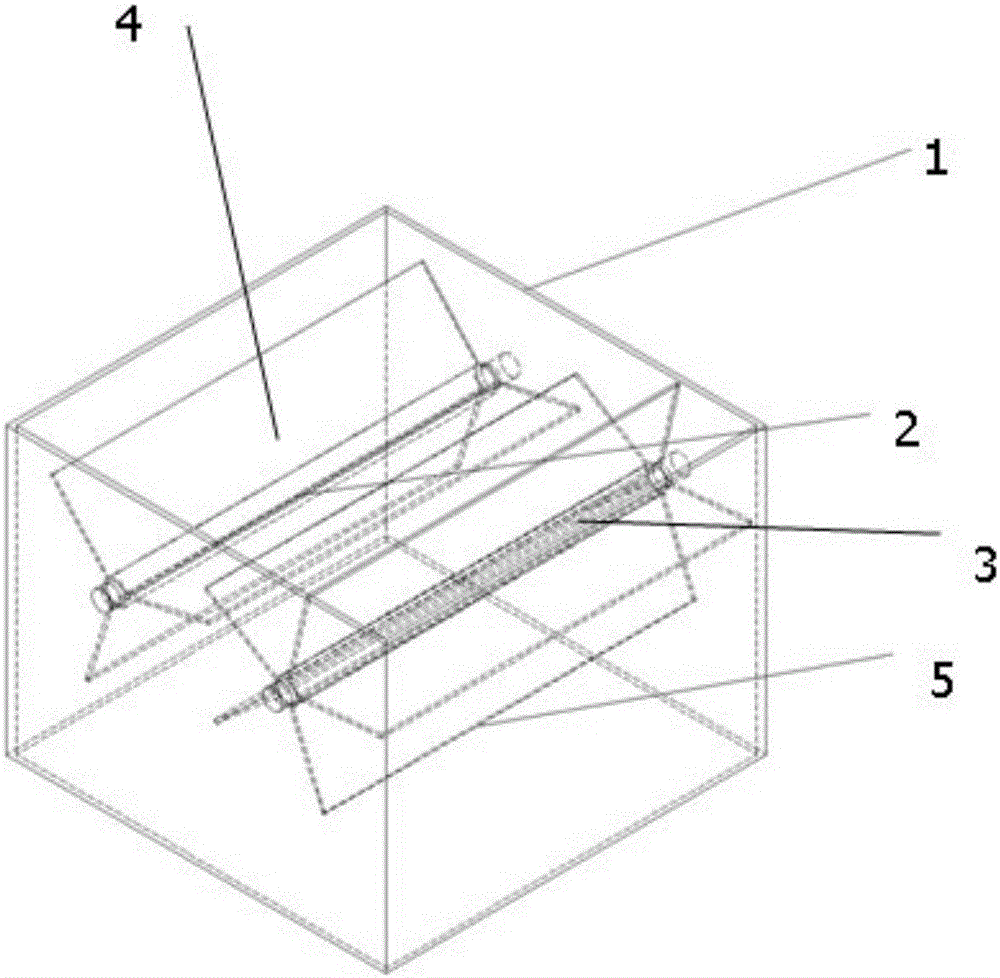

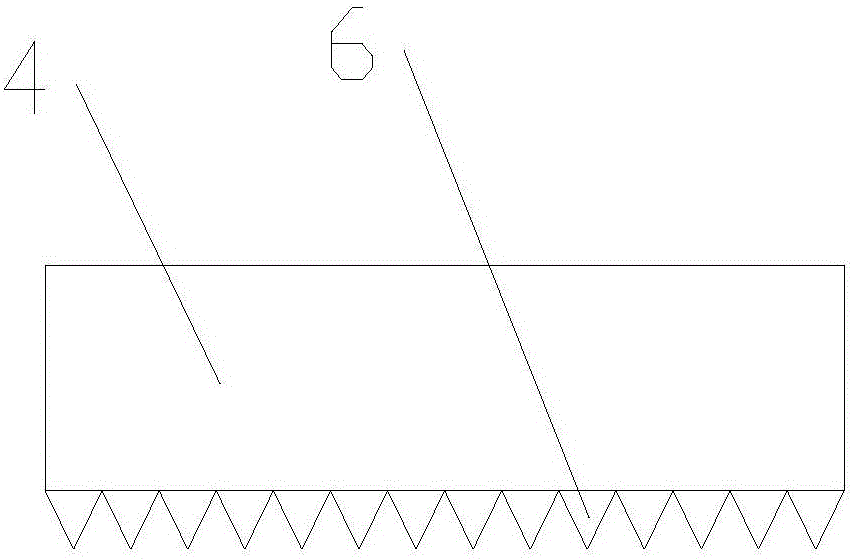

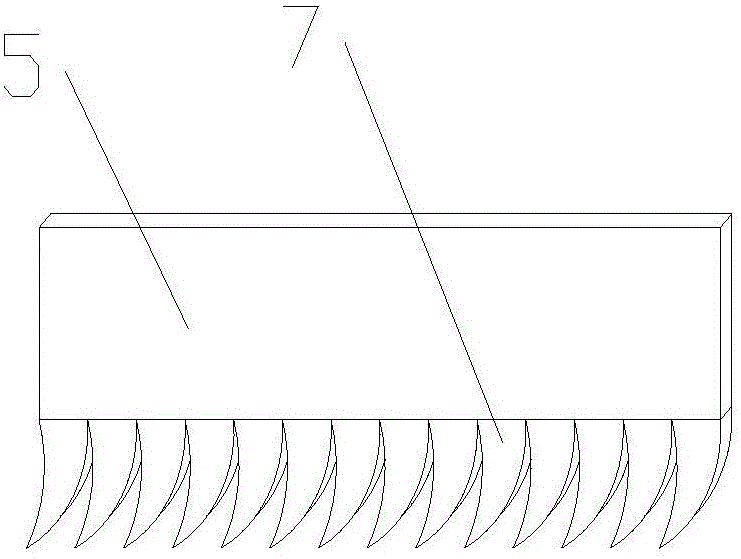

[0026] Such as figure 1 As shown, a grass feeder for a baler includes a grass feeder and a compression grass-following device. The grass feeder is provided with an inlet and an outlet. The driving shaft and the driven shaft are arranged in parallel; the driving shaft is provided with driving blades, and the driven shaft is provided with driven blades, and the blade areas of the driven blades and the driving blades overlap when the driven shaft rotates with the driving shaft , the compressing grass-sequencing device is arranged between the inlet and the outlet of the grass feeding cylinder, and the driving shaft is arranged close to the inlet. The number of driving blades is less than that of driven blades. The number of the driving blades is three, and the number of the driven blades is five. The vane areas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com