A waste cable stripping recovery device

A recycling device and waste cable technology, which is applied in the direction of cable installation device, cable installation, electronic waste recycling, etc., can solve the problem that the complete separation of cable conductors and cable insulation can not be realized, the cable can not be peeled online, and the workload of recycling can be increased. and other issues to achieve the effect of facilitating reuse, reducing occupation and pollution, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

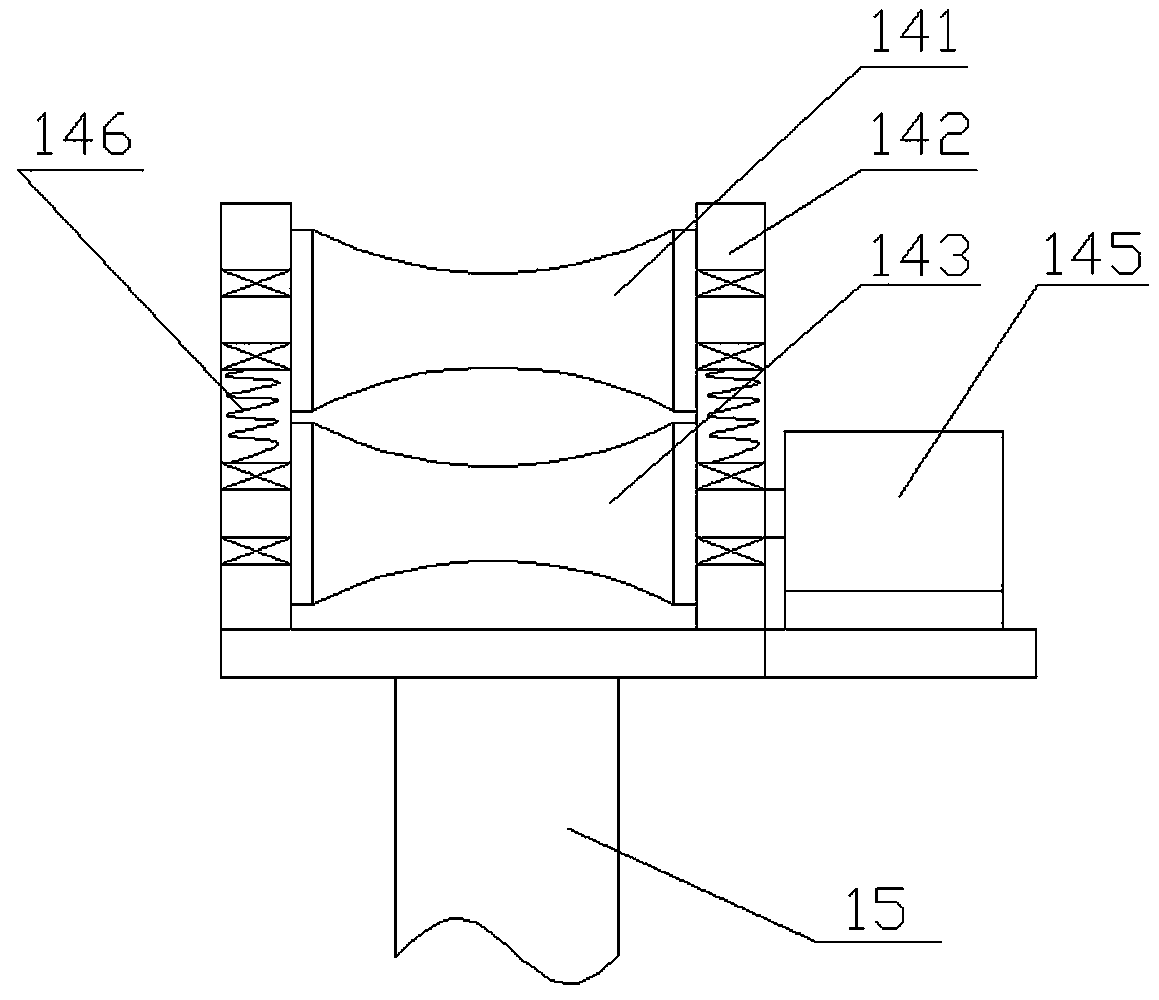

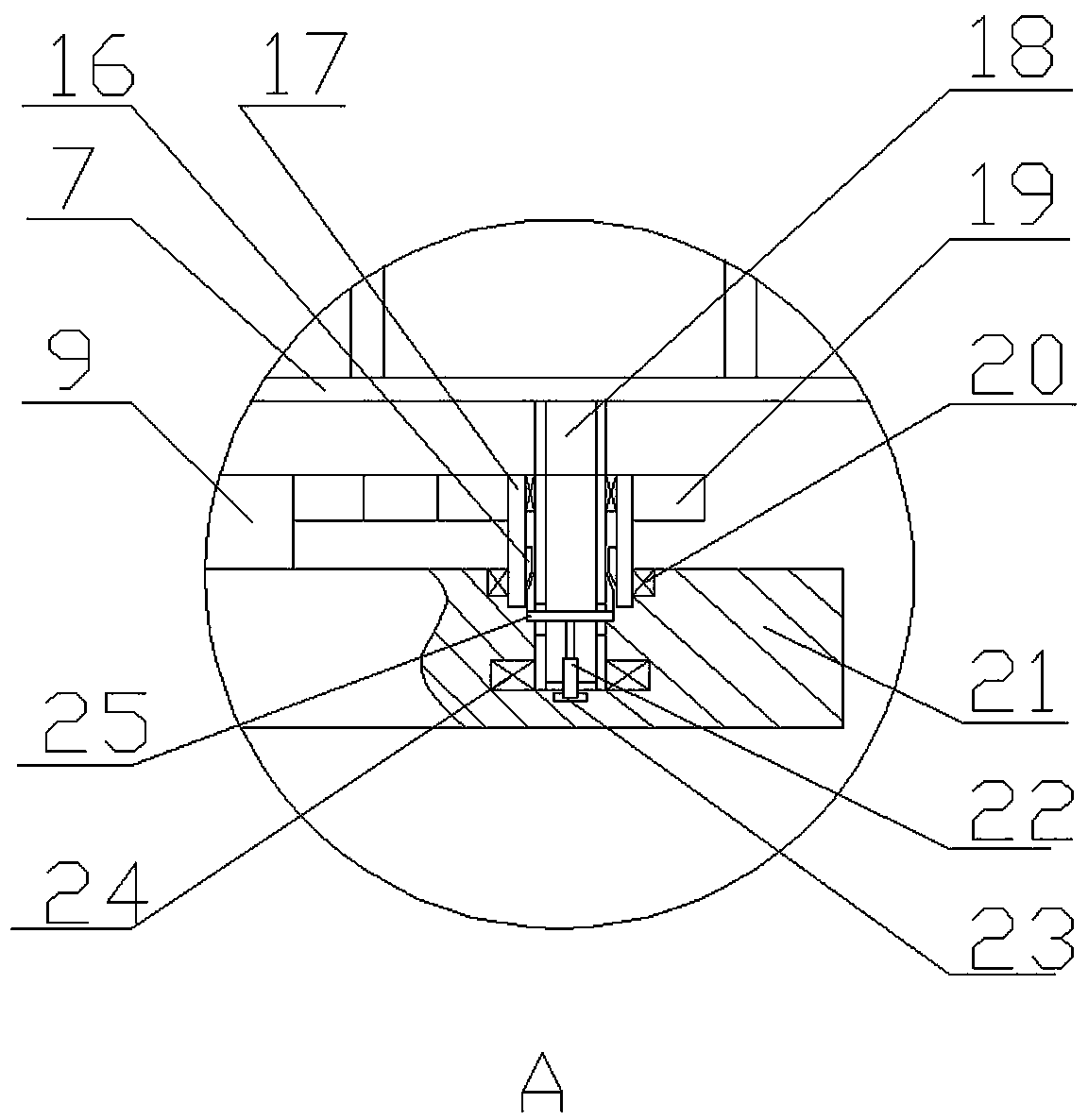

[0053] A waste cable stripping recovery device, comprising a base 1, a winding mechanism arranged on the base 1, three lead wire mechanisms arranged on the base 1 and matched with the winding mechanism, arranged on the base 1 The peeling mechanism on the top and matched with the three lead wire mechanisms, the guiding mechanism arranged on the base 1 and matched with the peeling mechanism, and arranged on one side of the base for coordinated control of the winding The control mechanism 26 of mechanism, lead wire mechanism, peeling mechanism and guiding mechanism;

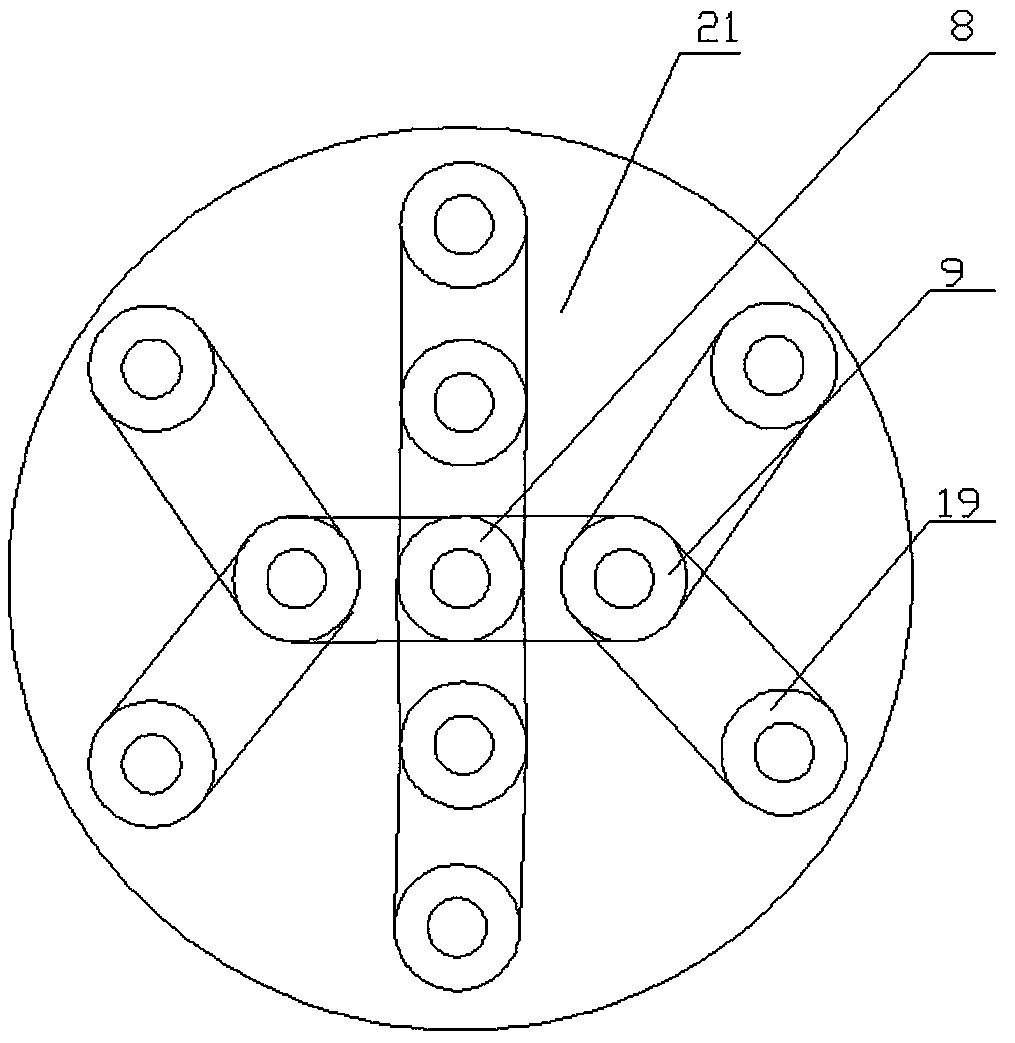

[0054] The winding mechanism includes a rotating shaft 4 arranged on the base 1, a rotating platform 21 arranged on the rotating shaft 4, a plurality of winding modules arranged on the rotating platform 21, and the winding module A transmission mechanism that cooperates and is arranged on the rotating platform 21 to drive the winding module;

[0055] The rewinding wheel includes a rewinding wheel 79, a plurality of...

Embodiment 2

[0072] It differs from Embodiment 1 in that: a guide plate 129 provided on the annular knife holder 124 for guiding the outer skin.

[0073] The upper half of the lead rod 11 is provided with a third telescopic rod.

[0074] The telescopic rod 22 is an electric telescopic rod with a rotary joint 23 at the bottom, and a brush is provided at the lower end of the electric telescopic rod.

[0075] The upper end of the retractable telescopic rod 76 is provided with a retractable ring 80 for movably connecting with the tension rod 81 .

[0076] The outer wall of the upper end of the winding support rod 75 is provided with a plurality of auxiliary gear rods 77 for limiting the position of the wire reel.

[0077] In this embodiment, the base is set on the car or the wheels are set on the bottom surface, which can realize the free movement of the device and enhance the flexibility; and the guide plate adopted is a rectangular groove, which can well control the cut skin , to avoid dis...

Embodiment 3

[0079] Such as Figure 10-12 As shown: the difference between it and the second embodiment is that four first positioning protrusions 28 for positioning are set on the rotating platform 21, and the first positioning protrusions 28 matched with the first protrusions 28 are set on the base 1. a positioning switch 31, and the first positioning switch 31 is interconnected with the control mechanism 26;

[0080] Four second positioning projections 29 for positioning are arranged on the lower end surface of the winding wheel, and a second positioning switch 30 matched with the second positioning projections 29 is provided on the rotating platform 21, and The second positioning switch 30 is connected to the control mechanism 26 for signals.

[0081] The first positioning protrusion and the second positioning protrusion adopted in this embodiment are all four-sided platforms; and the first positioning protrusion adopted can also be arranged on the rotating platform, and the protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com