Protein solid beverage and preparation method thereof

A solid beverage and protein technology, applied in the field of vegetable protein beverages, can solve the problems of discarding, liver burden, health problems, etc., and achieve the effects of convenient operation, promotion of digestion and absorption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

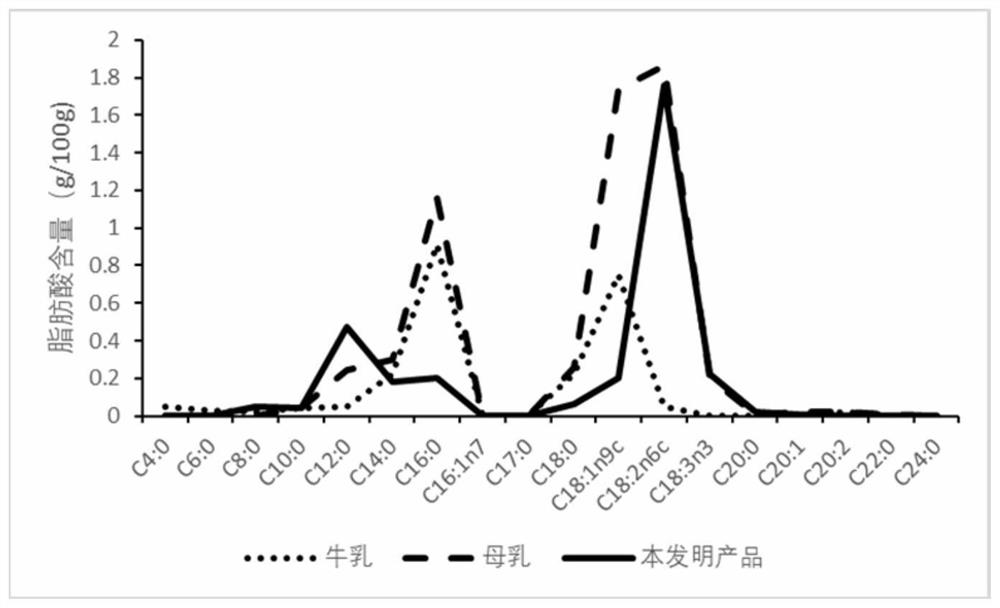

Image

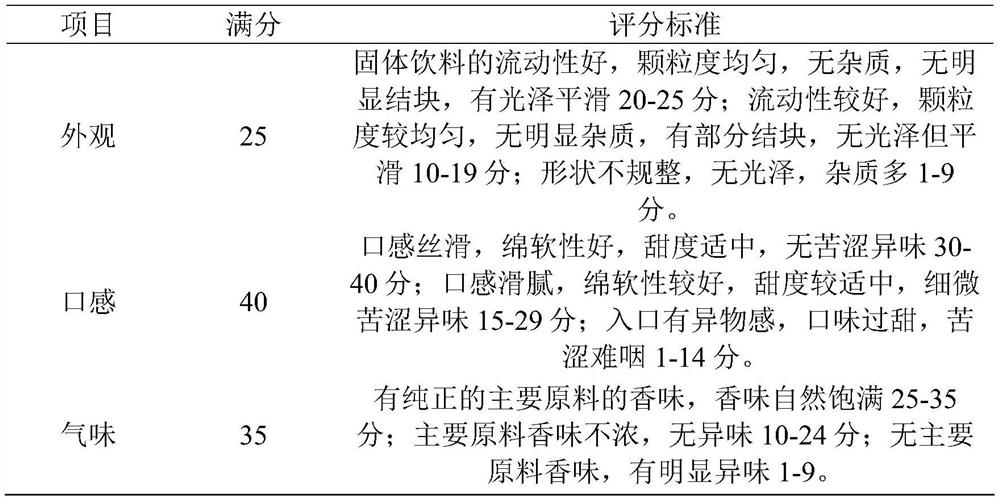

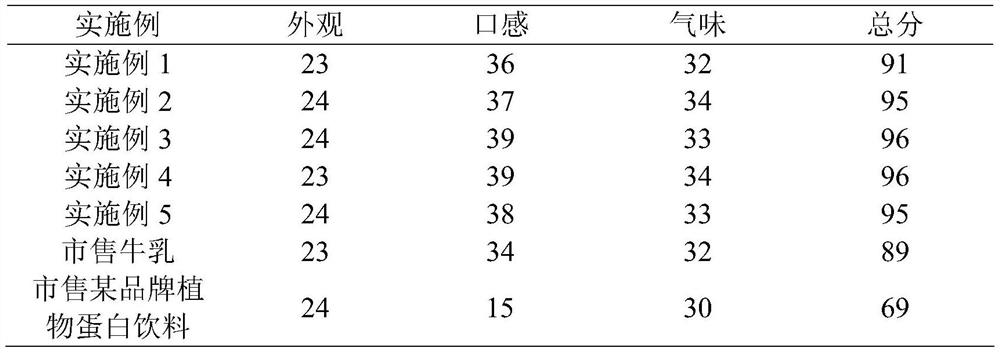

Examples

Embodiment 1

[0031] A protein solid drink rich in plant seeds, based on the total weight of 100g, including 15g of pine nuts, 15g of coconut oil, 45g of coconut milk, 8g of sodium caseinate, 10g of enzymatic oatmeal powder, 5g of perilla seed oil, Mono- and diglyceride fatty acid esters 1.8g, sodium tripolyphosphate 0.1g and sodium stearoyl lactylate 0.1g.

[0032] A method for preparing a protein solid drink rich in plant seeds, comprising the steps of:

[0033] 1) Refining: Weigh 15g of pine nut kernels and add them to 50ml of hot water at about 60°C, keep cutting for 20min after refining;

[0034] 2) Oil phase preparation: weigh 15g of coconut oil, (in winter or when the room temperature is lower than 30°C) first preheat the coconut oil to a liquid state with a heating mantle, then heat the liquid coconut oil to 60°C, slowly add single and double Glycerin fatty acid ester 1.8g, keep the temperature of the oil phase at 60°C to ensure full dissolution;

[0035] 3) Water phase preparatio...

Embodiment 2

[0041] A protein solid drink rich in plant seeds, based on the total weight of 100g, including 10g of pine nuts, 10g of almonds, 20g of coconut oil, 30g of coconut milk, 8g of sodium caseinate, 15g of enzymatic oat powder, perilla seeds Oil 5g, mono- and diglyceride fatty acid ester 1.6g, sodium tripolyphosphate 0.2g and sodium stearoyl lactylate 0.2g.

[0042] A method for preparing a protein solid drink rich in plant seeds, comprising the steps of:

[0043] 1) Refining: Weigh 10g of pine nuts and 10g of almonds respectively, add 50ml of hot water at about 60°C, keep cutting for 20min after refining;

[0044] 2) Oil phase preparation: Weigh 20g of coconut oil, (in winter or when the room temperature is lower than 30°C) first preheat the coconut oil to liquid state with a heating mantle, then heat the liquid coconut oil to 66°C, slowly add single and double Glycerin fatty acid ester 1.6g, keep the temperature of the oil phase at 66°C to ensure full dissolution;

[0045] 3) Wat...

Embodiment 3

[0051] A protein solid drink rich in plant seeds, based on the total weight of 100g, including 15g of hazelnut kernels, 15g of coconut oil, 40g of coconut milk, 8g of sodium caseinate, 15g of enzymatic hydrolyzed oatmeal, 5g of perilla seed oil, single , 1.8g of diglycerin fatty acid ester, 0.1g of sodium tripolyphosphate and 0.1g of sodium stearoyl lactylate.

[0052] A method for preparing a protein solid drink rich in plant seeds, comprising the steps of:

[0053] 1) Refining: Weigh 15g of hazelnut kernels, add 50ml of hot water at about 60°C, keep cutting for 20min after refining;

[0054] 2) Oil phase preparation: Weigh 15g of coconut oil, (in winter or when the room temperature is lower than 30°C) first preheat the coconut oil to liquid state with a heating mantle, then heat the liquid coconut oil to 63°C, slowly add single and double Glycerin fatty acid ester 1.8g, keep the temperature of the oil phase at 63°C to ensure full dissolution;

[0055] 3) Water phase prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com