A meat cutting device for producing tribute meatballs

A technology of meat cutting and cutting mechanism, which is applied in poultry or fish processing equipment and meat field, which can solve the problems of time-consuming, laborious, inapplicable, and low work efficiency, and achieve the effects of avoiding pollution, improving work efficiency, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Aiming at the problems of time-consuming and labor-intensive manual meat cutting and low work efficiency, the invention provides a meat cutting device for producing tribute meatballs.

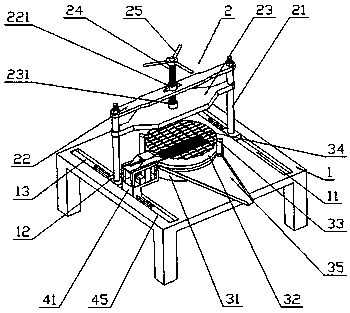

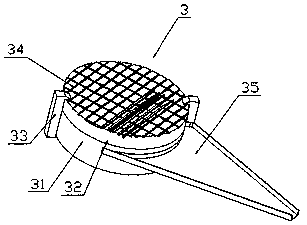

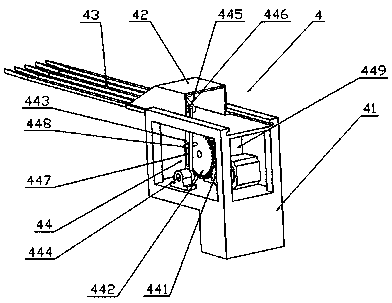

[0033] see Figure 1-3 , the present invention is a meat cutting device for producing tribute meatballs, comprising a stand 1, a pressing mechanism 2 arranged on the stand 1, a rotating mechanism 3 and a cutting mechanism 4;

[0034] Pressing mechanism 2 comprises support 21, support plate 22, pressing plate 23 and leading screw 24, and support plate 22 is arranged on the upper end of support 21, and support 21 and support plate 22 are fixedly connected in door shape, and support plate 22 is provided with hollow cylindrical platform 221, the inner surface of the cylindrical platform 221 is provided with threads corresponding to the lead screw 24, the pressing plate 23 is arranged on the lower end of the bracket 21, the connecting seat 231 is provided on the pressing plate 23, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com