Sanitary napkin small-bag triple-folding process

A technology of sanitary napkins and craftsmanship, applied in sanitary napkins, folded thin materials, transportation and packaging, etc., can solve the problems of wrinkling, improper folding, and loose fitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

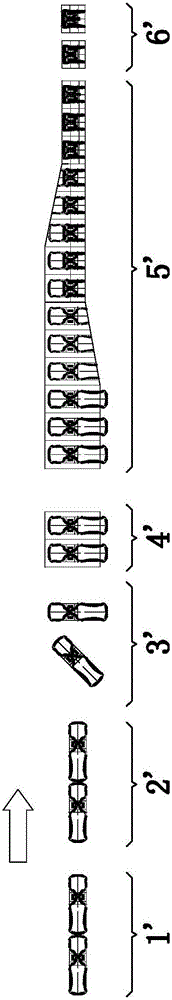

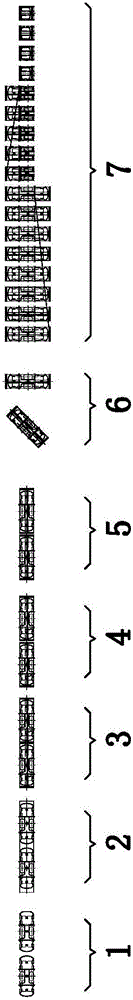

[0014] figure 2 As shown, the present embodiment provides a three-fold process of a sanitary napkin packet, comprising the following steps:

[0015] In the first step, after the cotton core is combined with the surface layer and the bottom layer, it is a combination of continuous long strips of sanitary napkins. This is the first stage 1, and then the covering mechanism is used to reversely cover the small envelope. This is the second stage. Second stage 2;

[0016] The second step is to heat seal and bond the two ends of each sanitary napkin with a heat sealing device after covering the small film. This is the third stage 3, and then cut to form an independent sanitary napkin product. This is the fourth stage 4. After cutting, turn the sanitary napkin 180 degrees with the conveyor belt, which is the fifth stage 5;

[0017] The th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com