Patents

Literature

32results about How to "Reduce adverse conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods for managing throughput of point of sale devices

ActiveUS20050087594A1Easy to processGood user interfaceComplete banking machinesFinanceChequeAuthorization

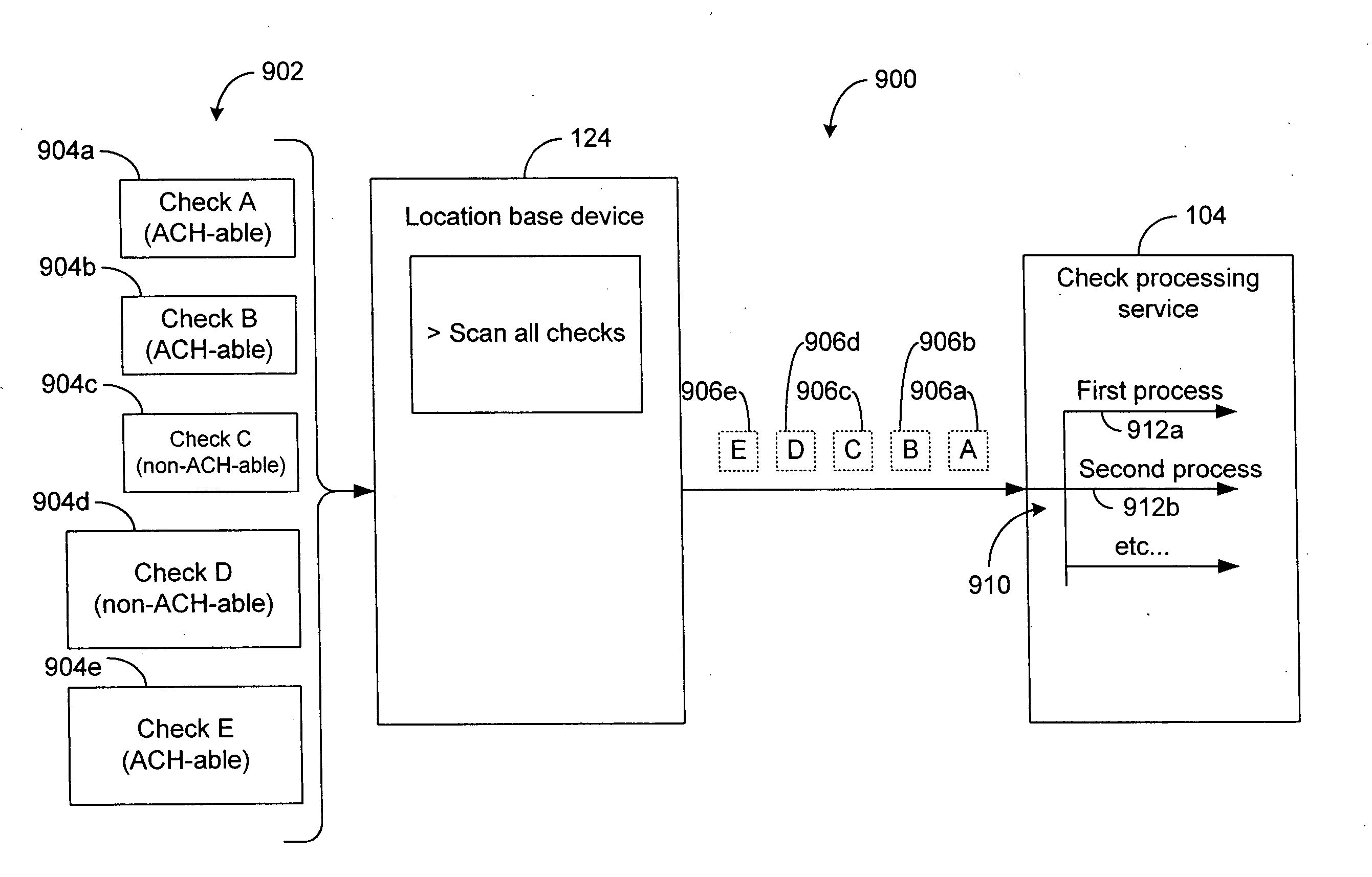

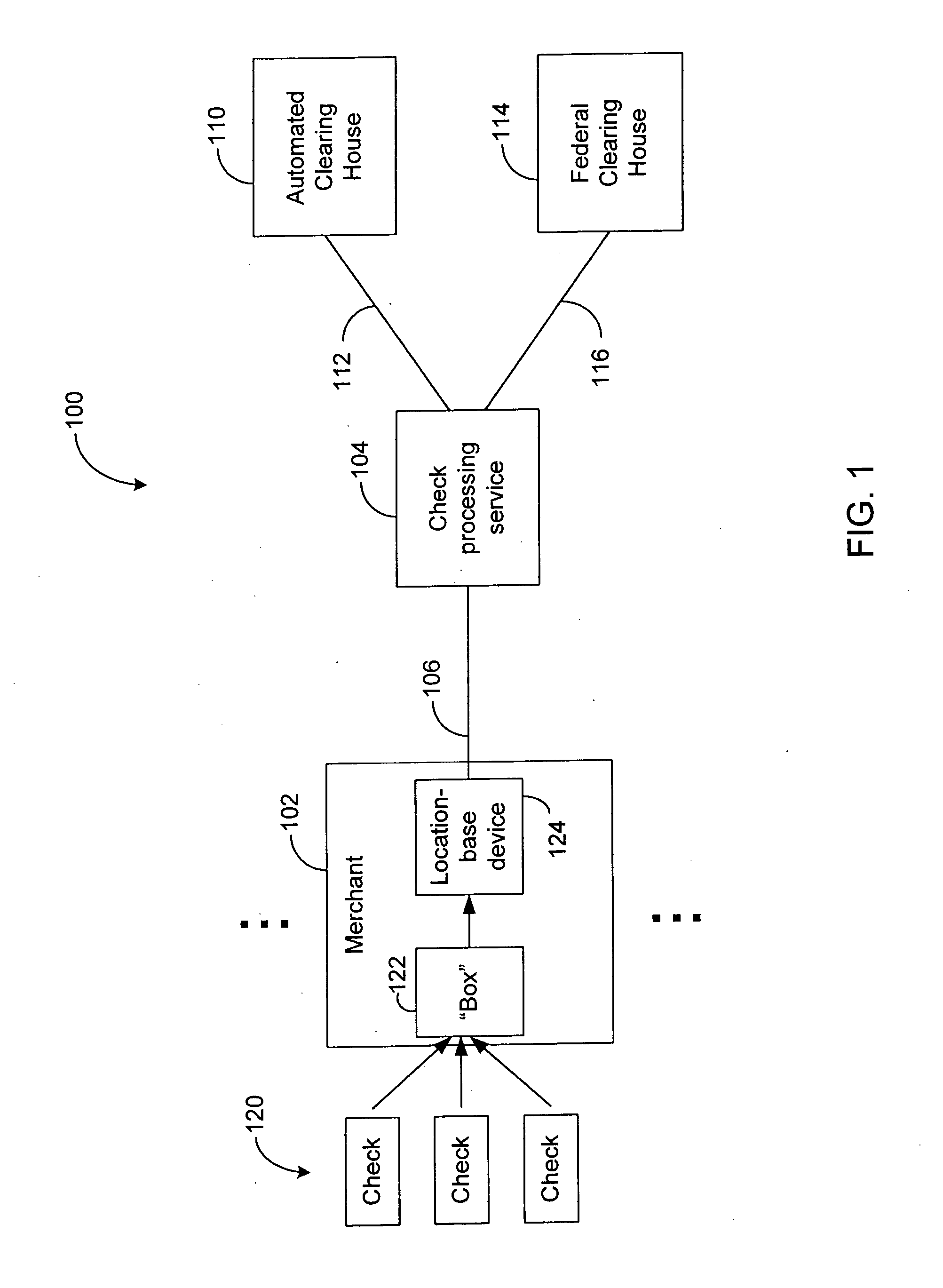

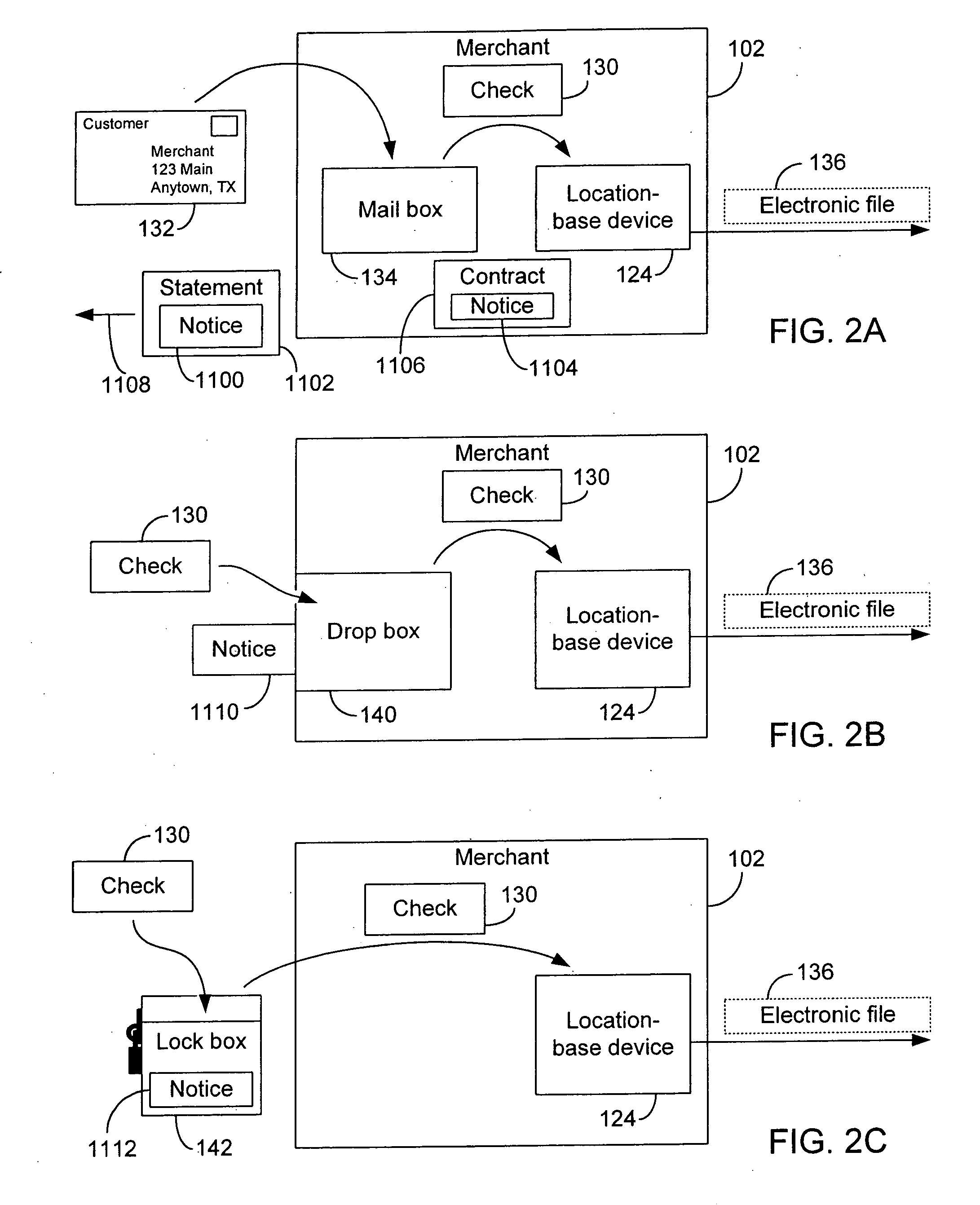

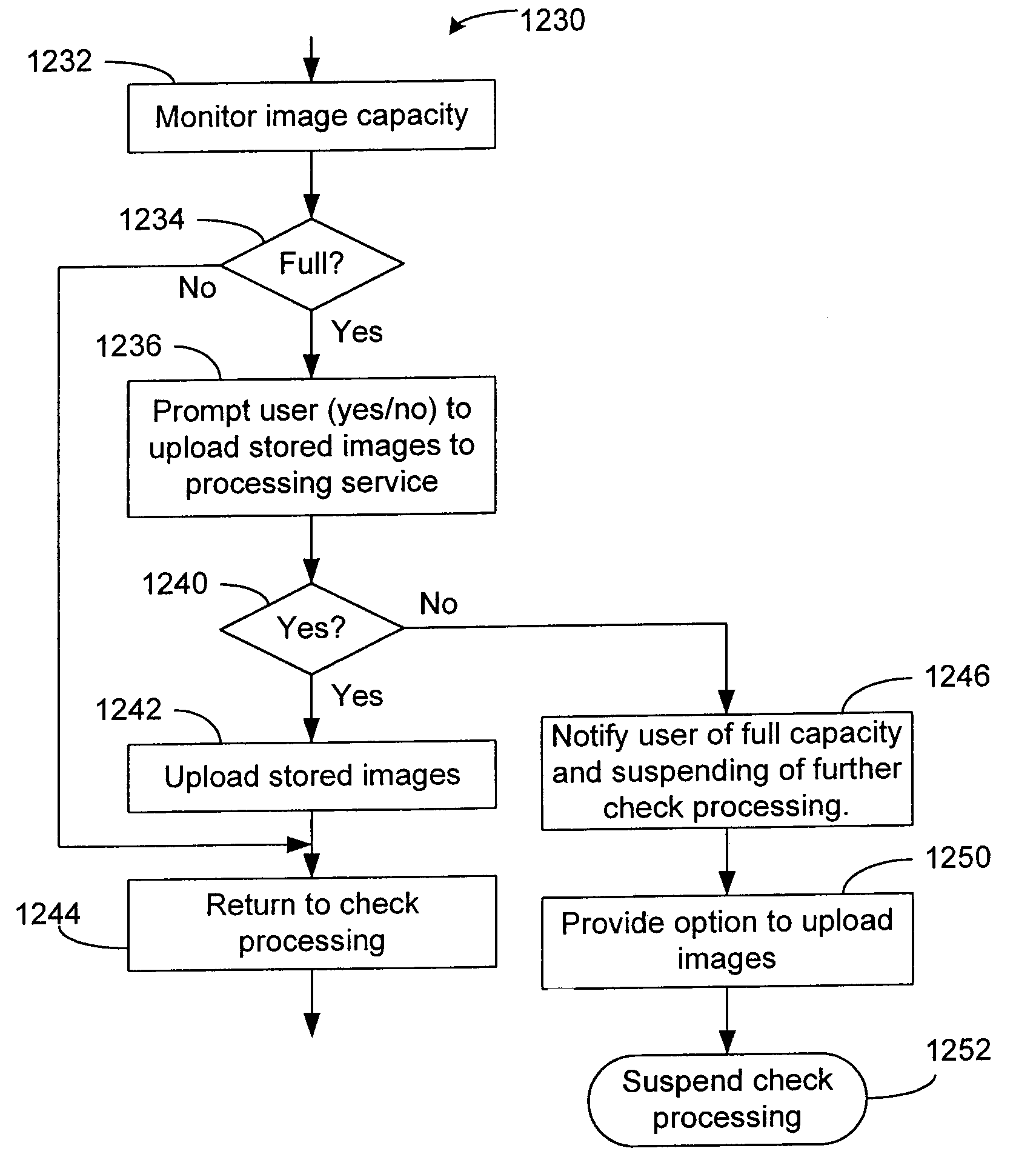

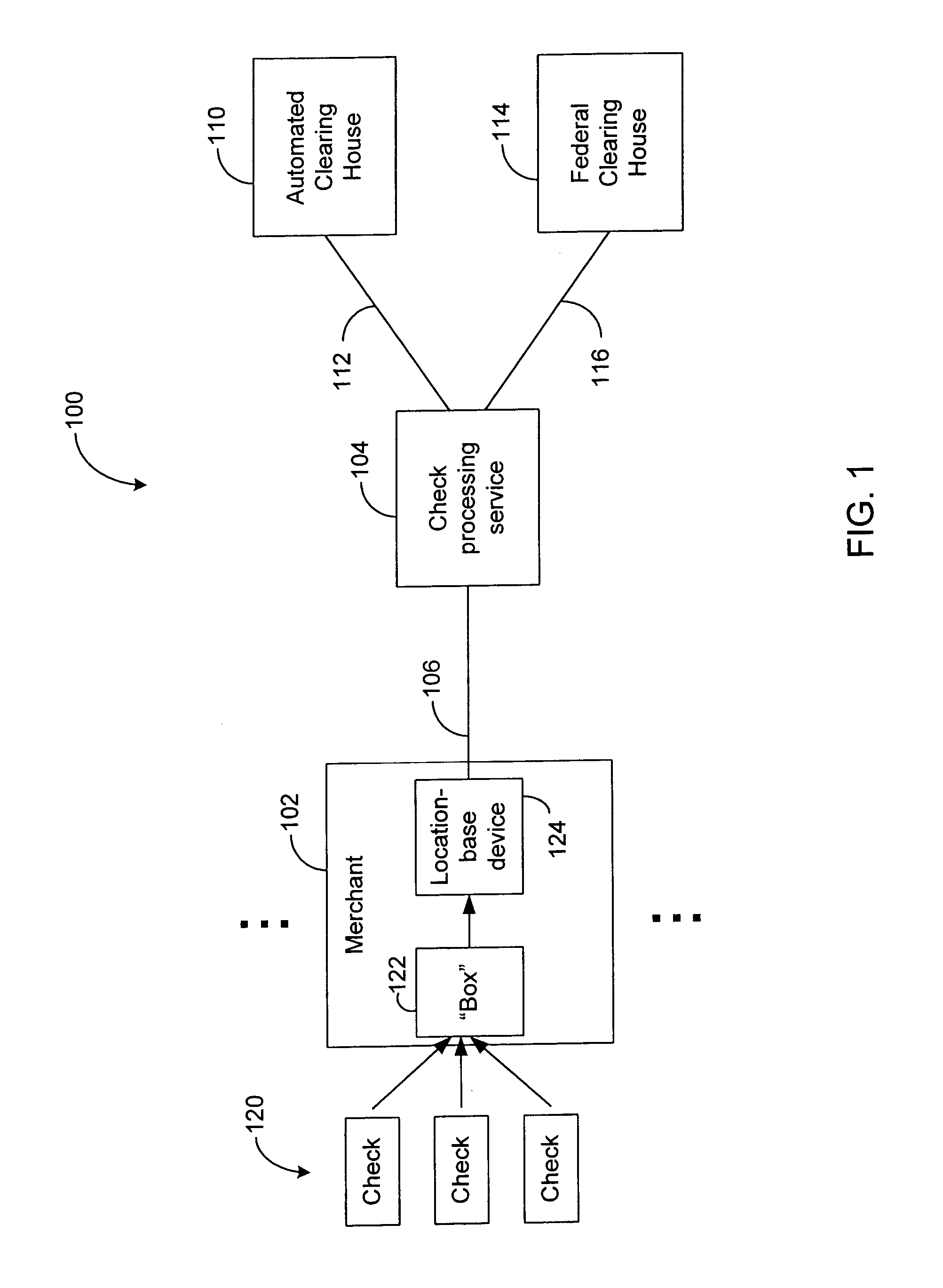

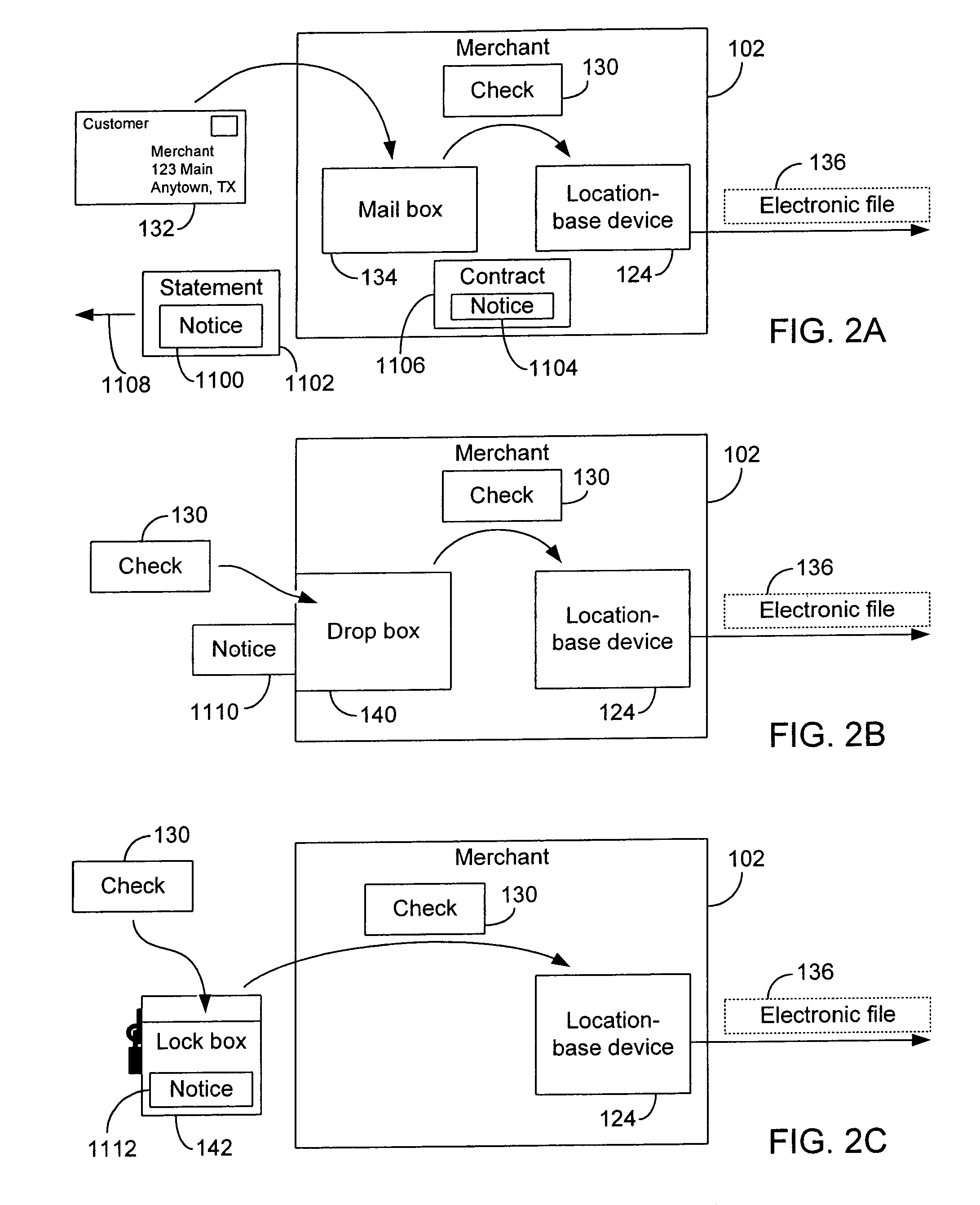

Systems and methods for electronically processing accounts receivable (AR) check transactions via a location-base device associated with a merchant. The location-base device, such as a point-of-sale (POS) device, can be configured to perform various functions that facilitate processing of AR checks. Such functions may include improved user interface, an ability to handle a repetitive input parameter, an ability to handle multiple merchant identifiers, an ability to generate multiple receipt types, an ability to edit check transactions, an ability to manage throughput of the device, and an ability to allow scanning of different types of checks so as to allow subsequent processing of the scanned checks to be different based on the type of the check. The location-base device configured in one or more of the foregoing manner facilitates a check authorization process performed by a check processing service.

Owner:FIRST DATA

Systems and methods for managing throughput of point of sale devices

ActiveUS7070092B2Easy to processFacilitate the processComplete banking machinesFinanceProgramming languageCheque

Owner:FIRST DATA

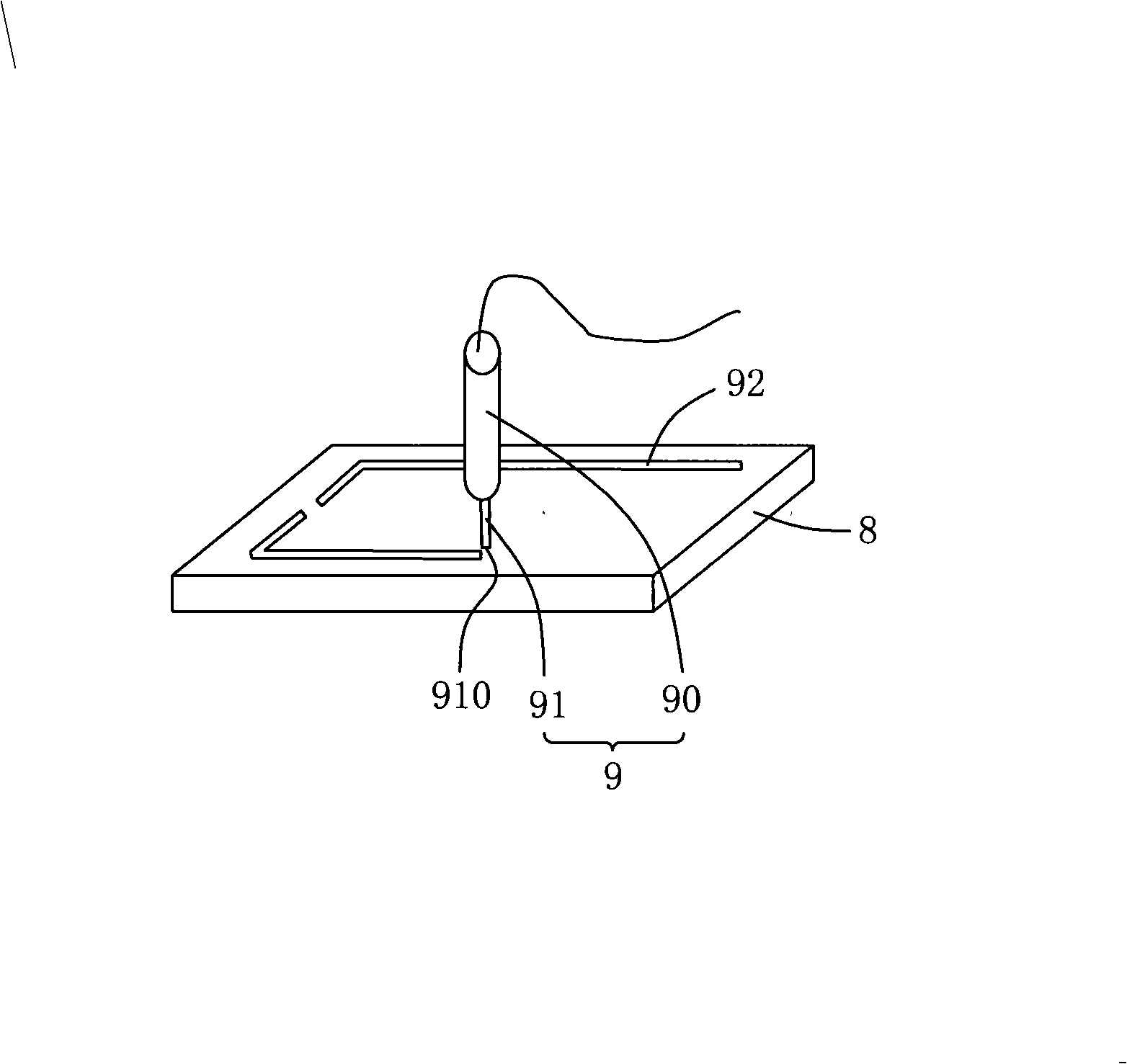

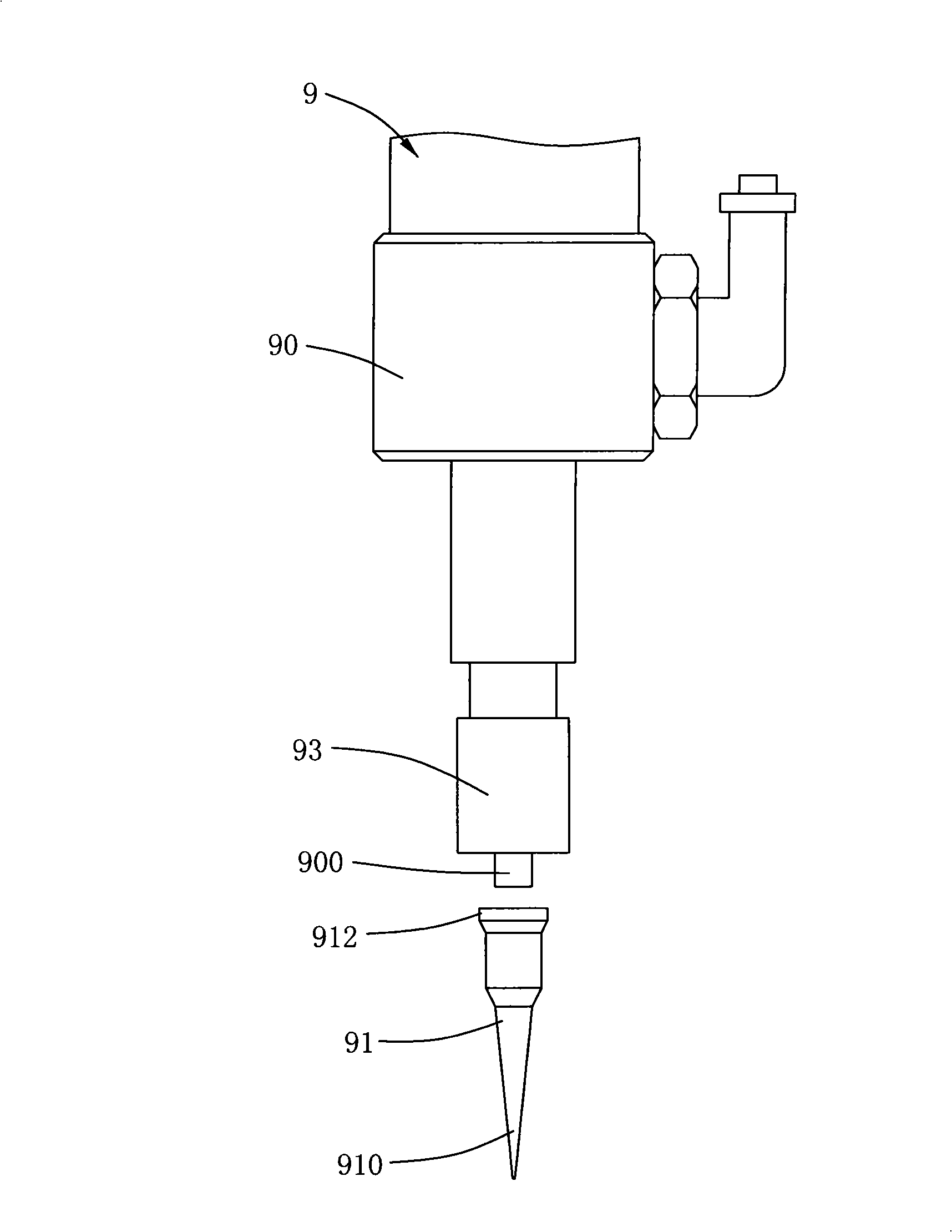

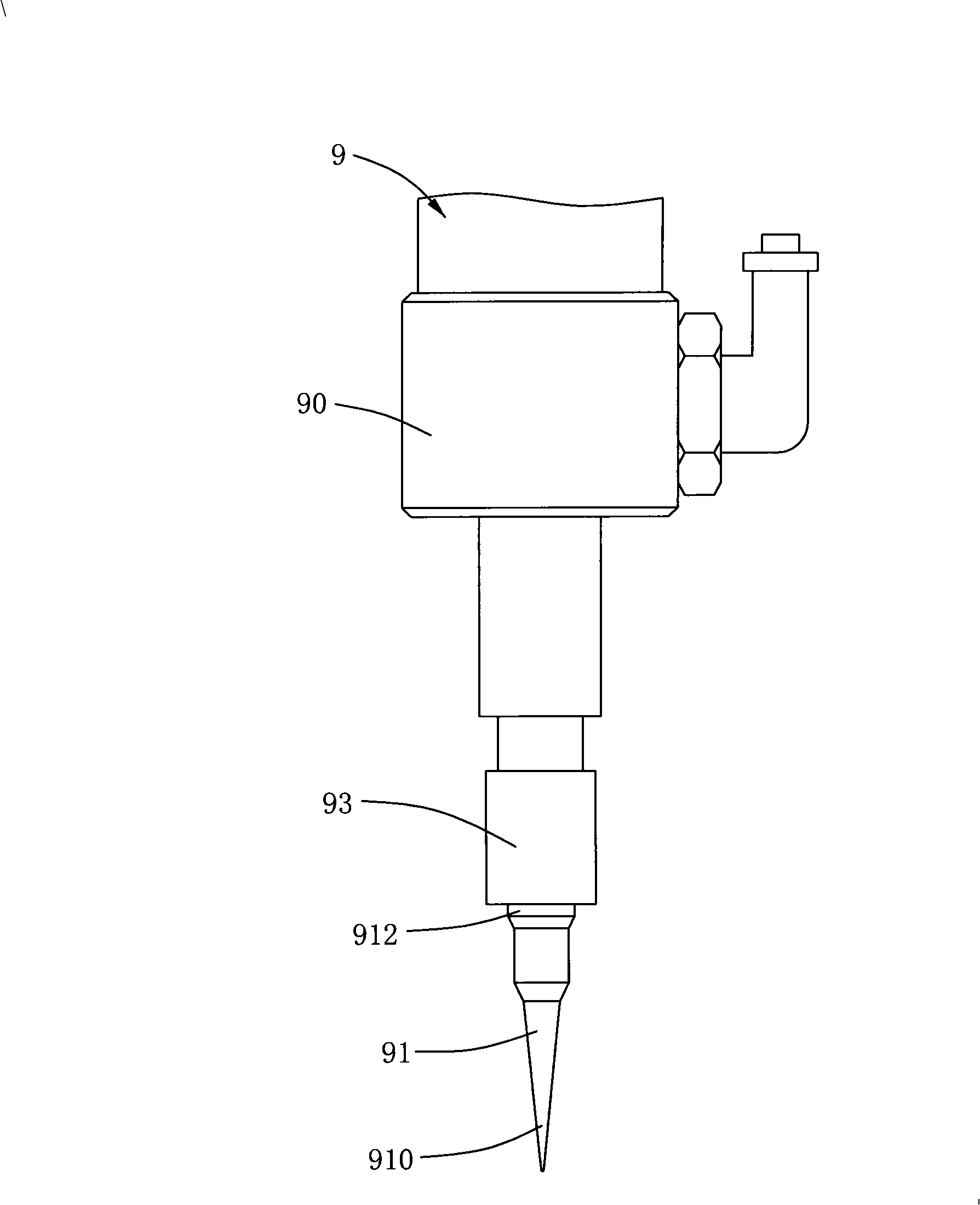

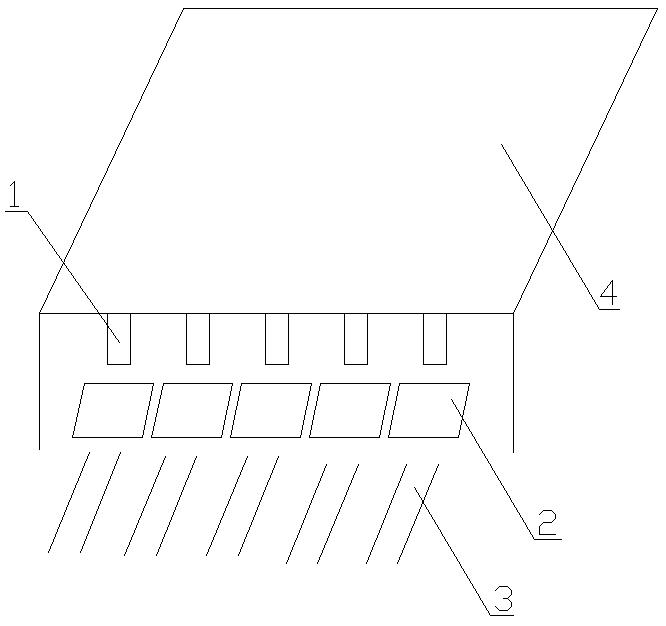

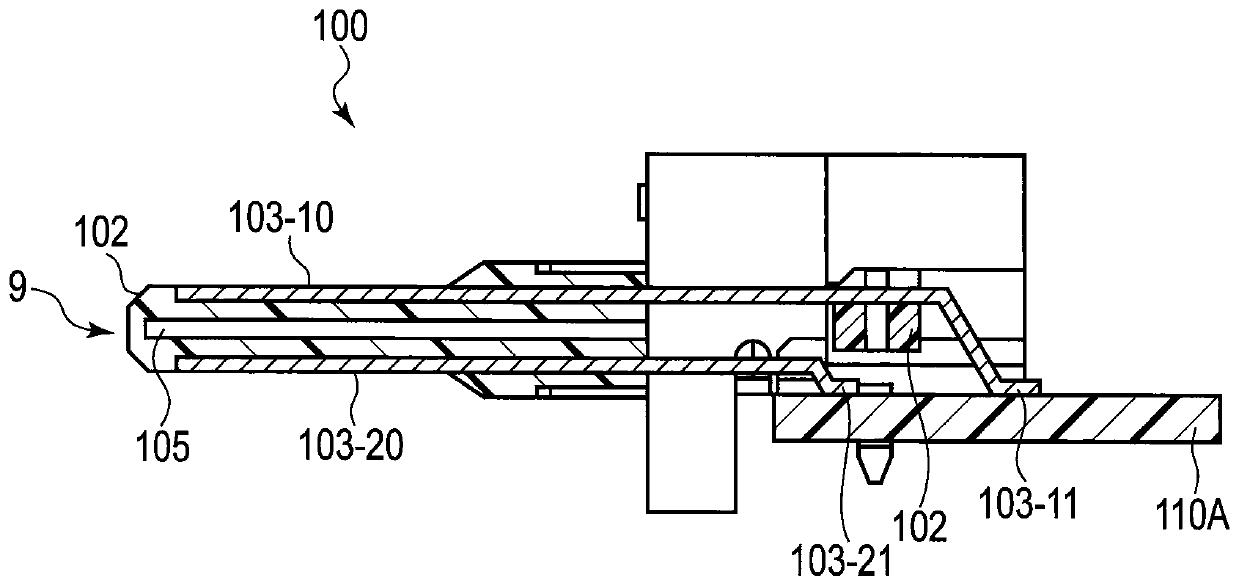

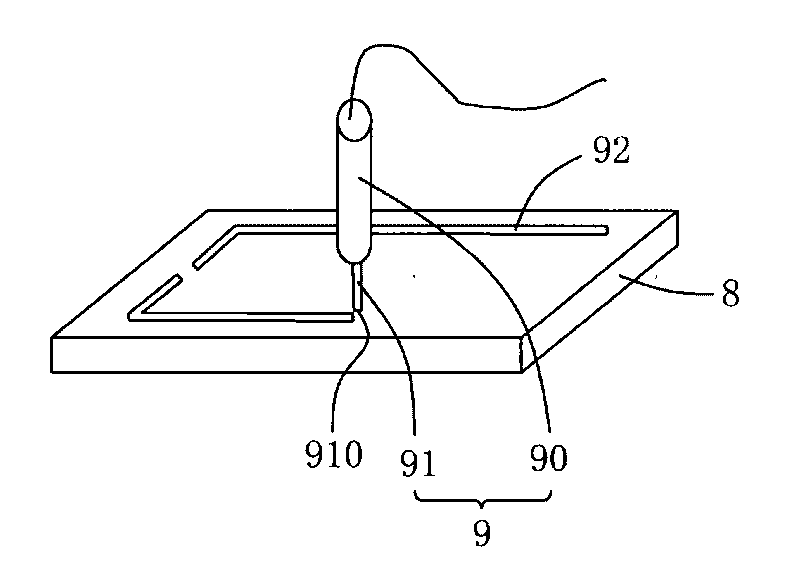

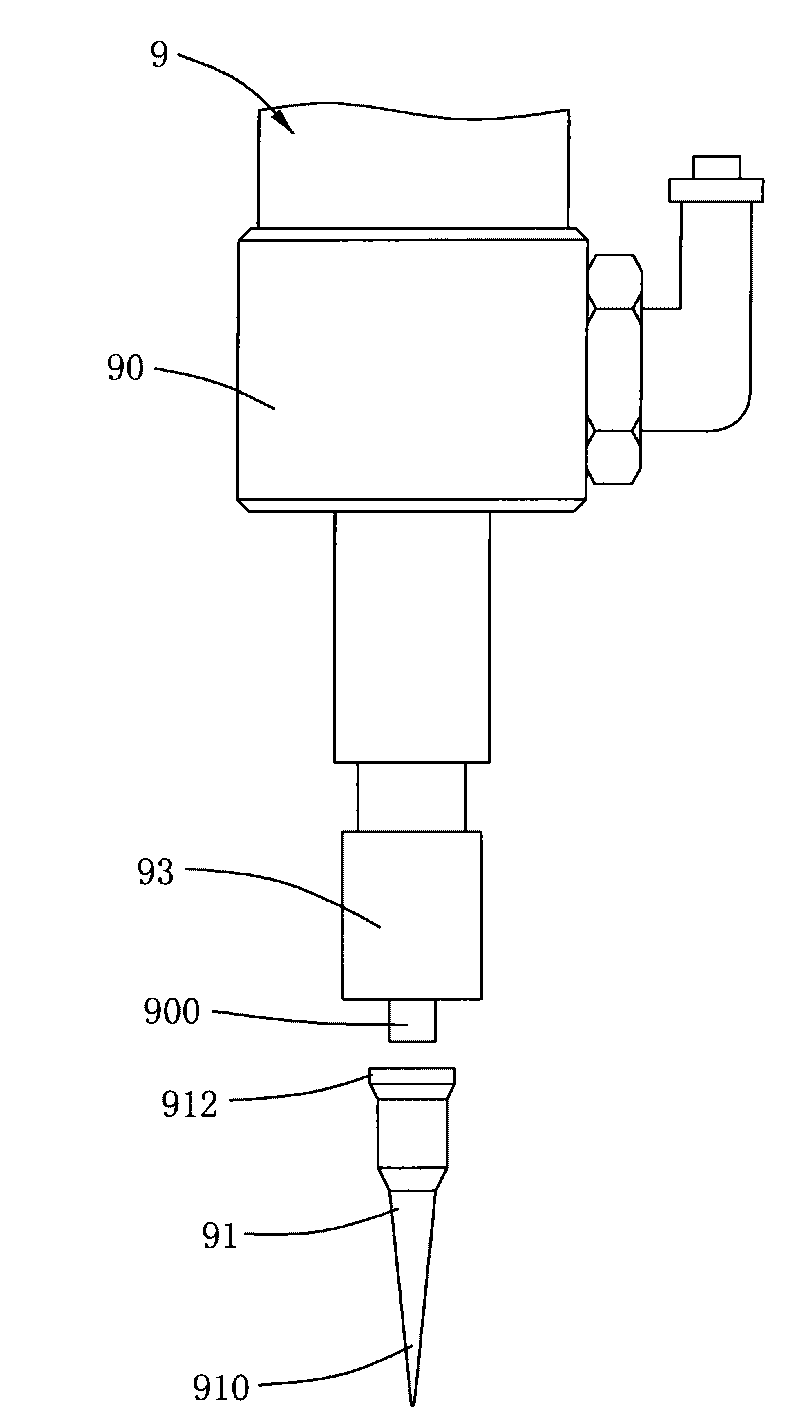

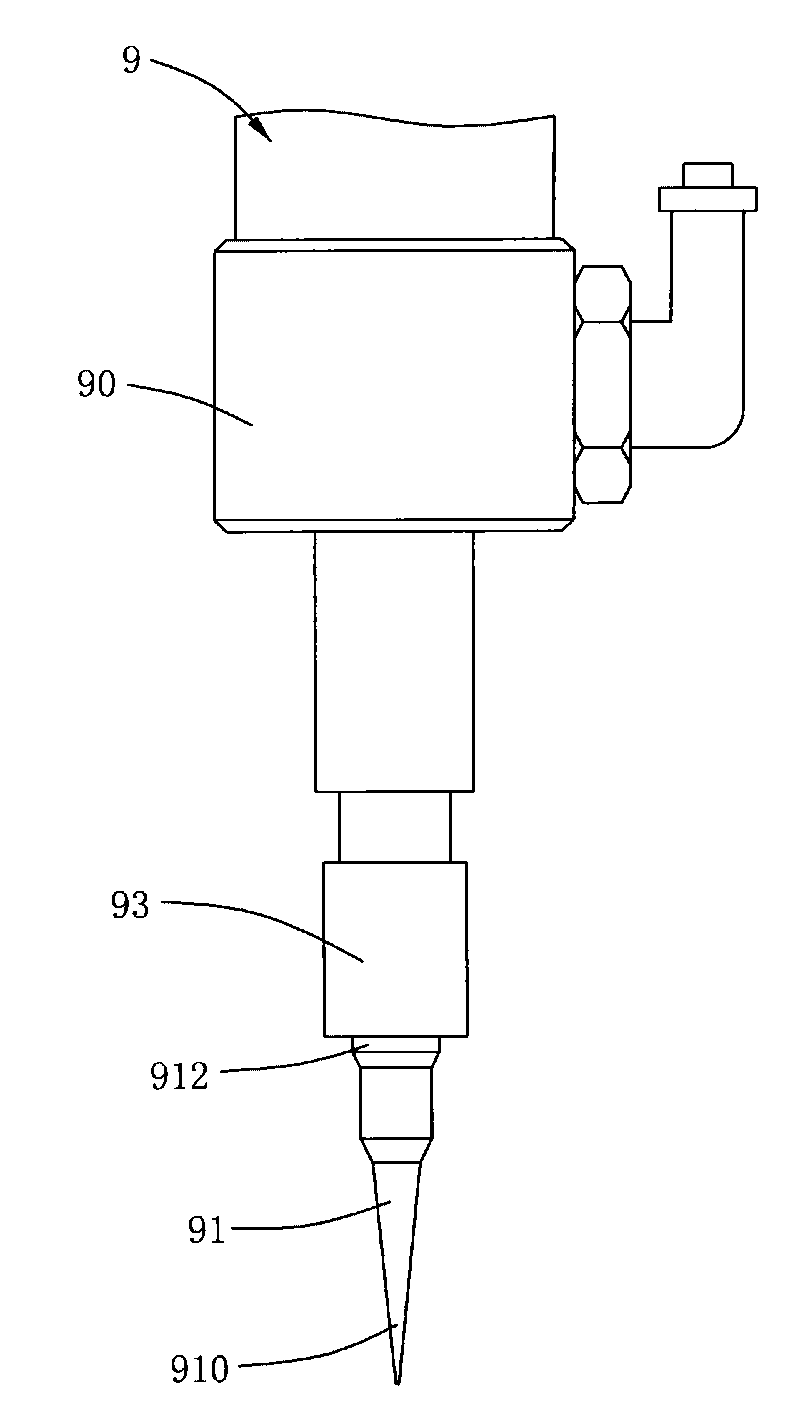

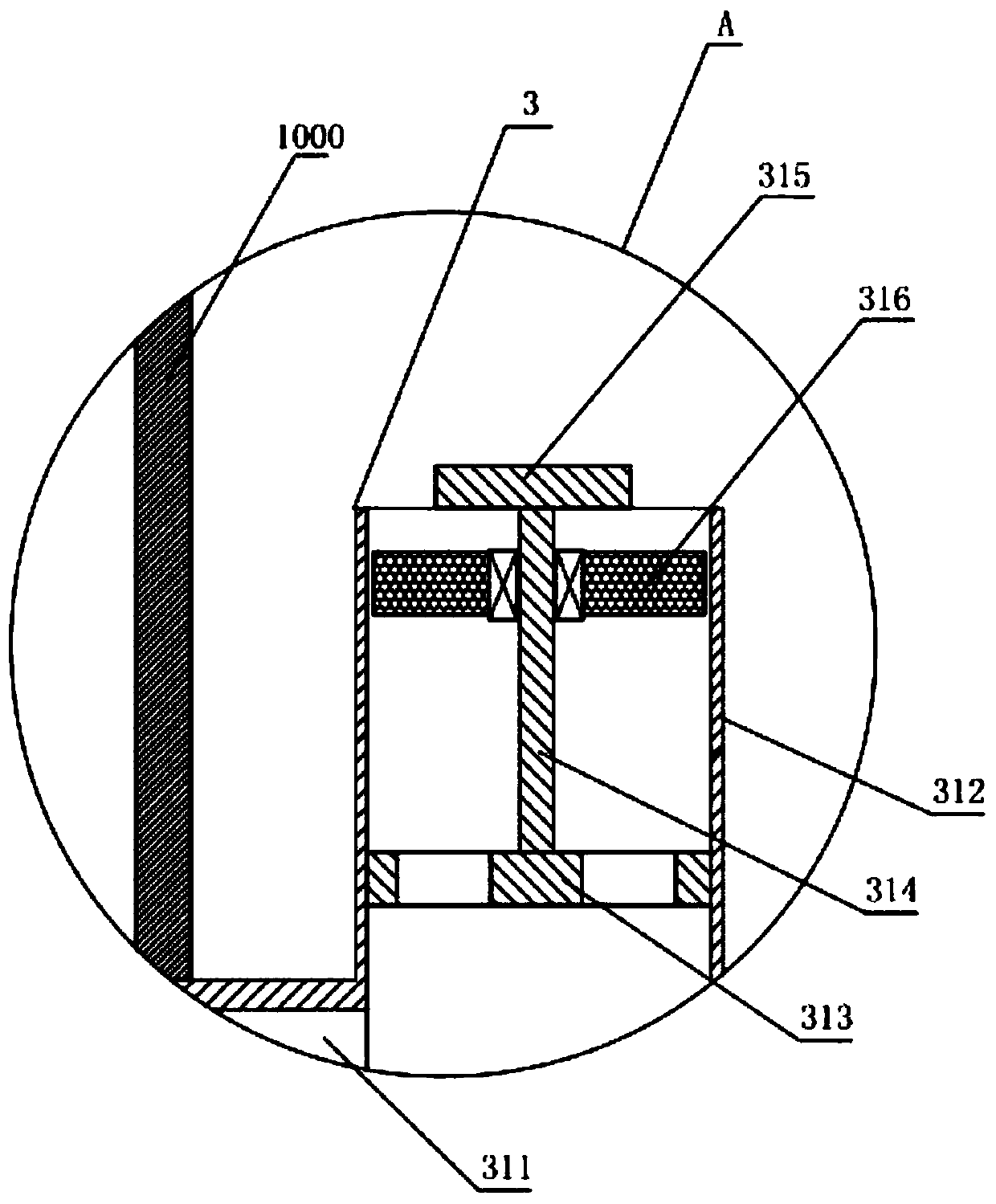

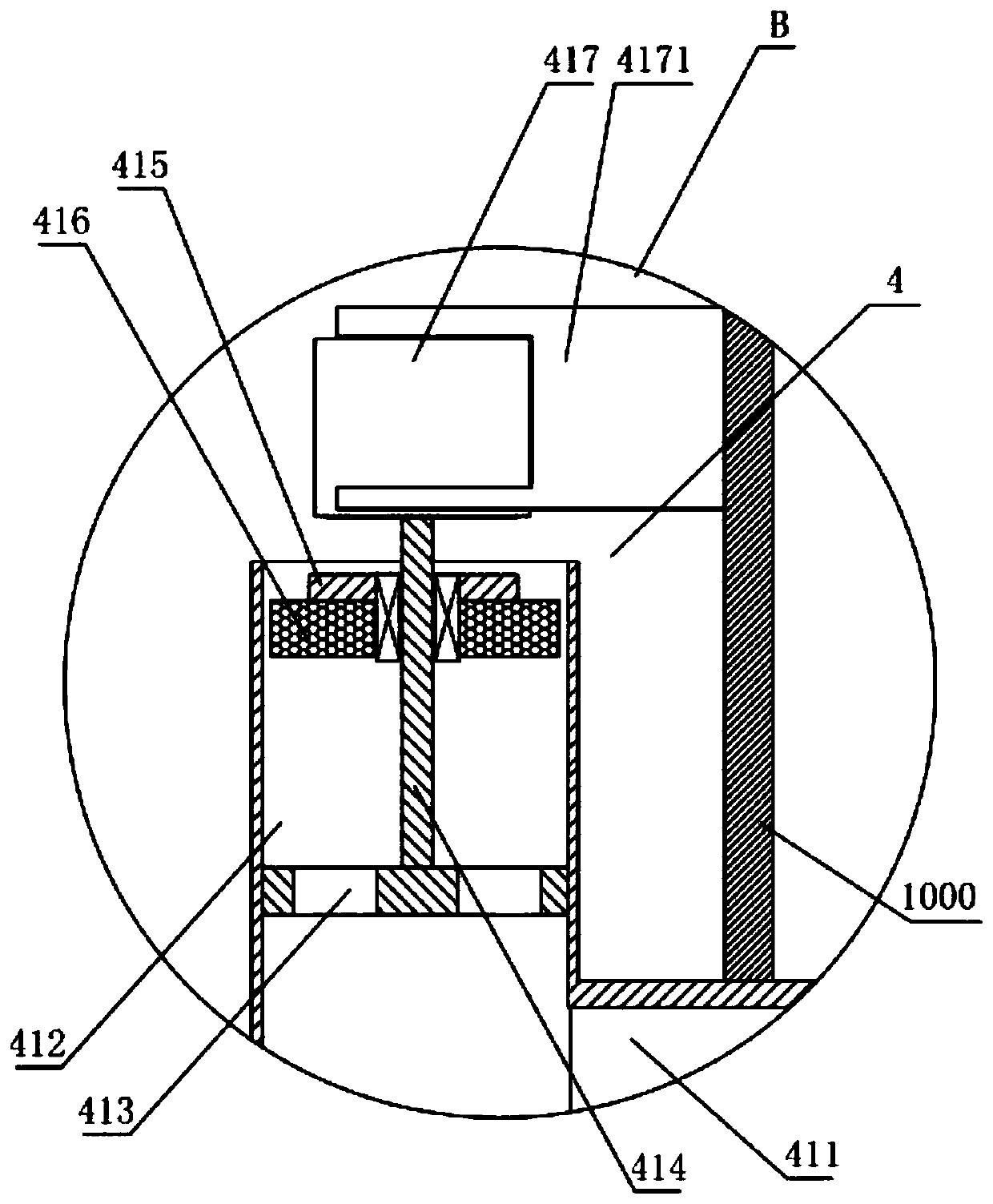

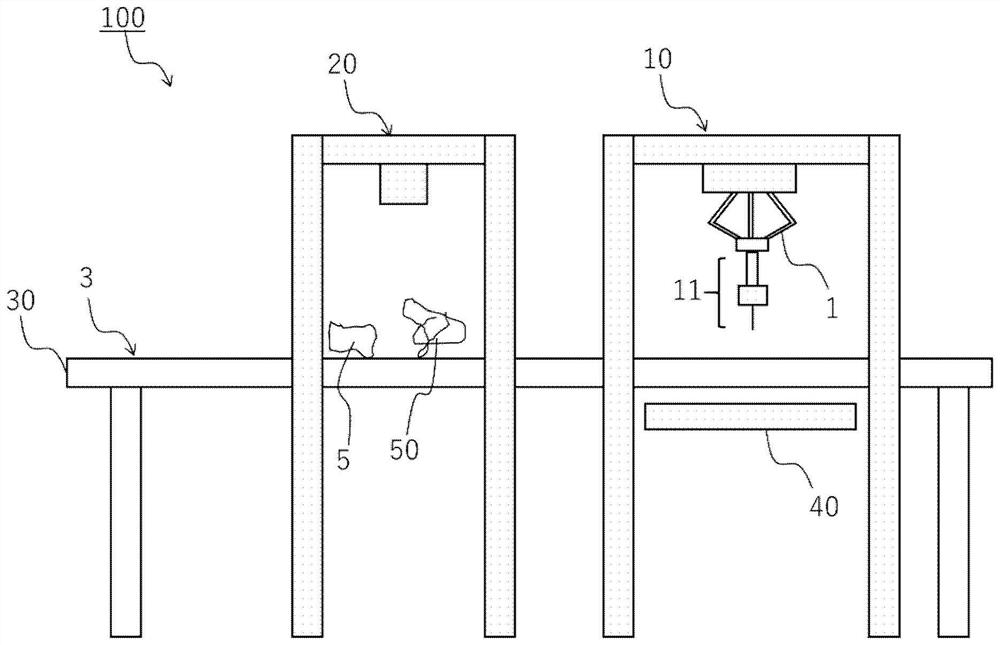

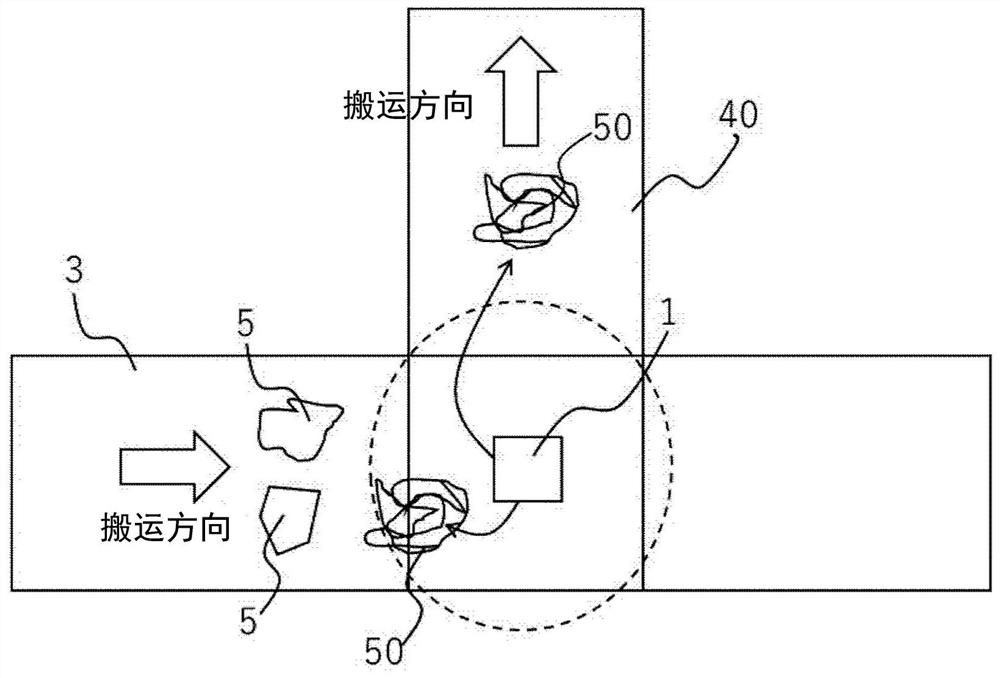

Glue spreading apparatus, using and maintaining method for the glue spreading apparatus

InactiveCN101318169AHigh strengthNo bending deformationLiquid surface applicatorsSpraying apparatusConical tubeMechanical engineering

The invention discloses a rubberizing device, comprising a base, a pin base, a rubberizing pin on the pin base, a fixing mechanism and a pin protecting mechanism. In an embodiment of the invention, the fixing mechanism comprises a slide block and a clamp; wherein the slide block can be arranged on a guide rail of the base in a sliding way, and drives the pin base and the rubberizing pin to lift up and down to adjust the distance between the fixing mechanism and the pin protecting mechanism; the clamp is connected with the slide block to clamp the pin base. The pin protecting mechanism comprises a conical tube; the conical tube can be separately sheathed on the outside of the rubberizing pin. During the use and maintenance of the rubberizing device, when the distance between the fixing mechanism and the pin protecting mechanism is increased, the rubberizing pin can be moved out of the pin protecting mechanism thus realizing quick replacement and improving the operation efficiency.

Owner:AU OPTRONICS (XIAMEN) CORP +1

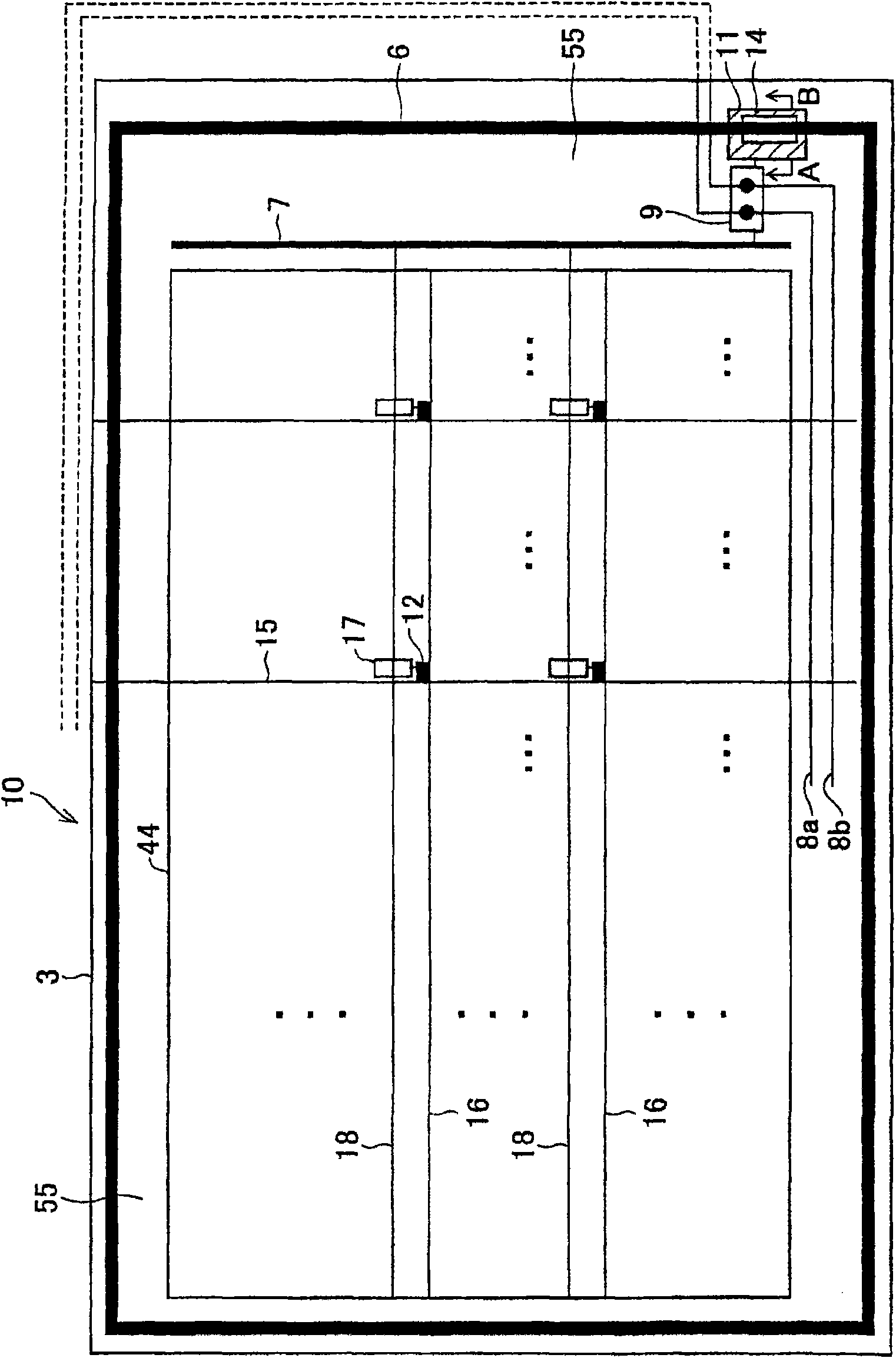

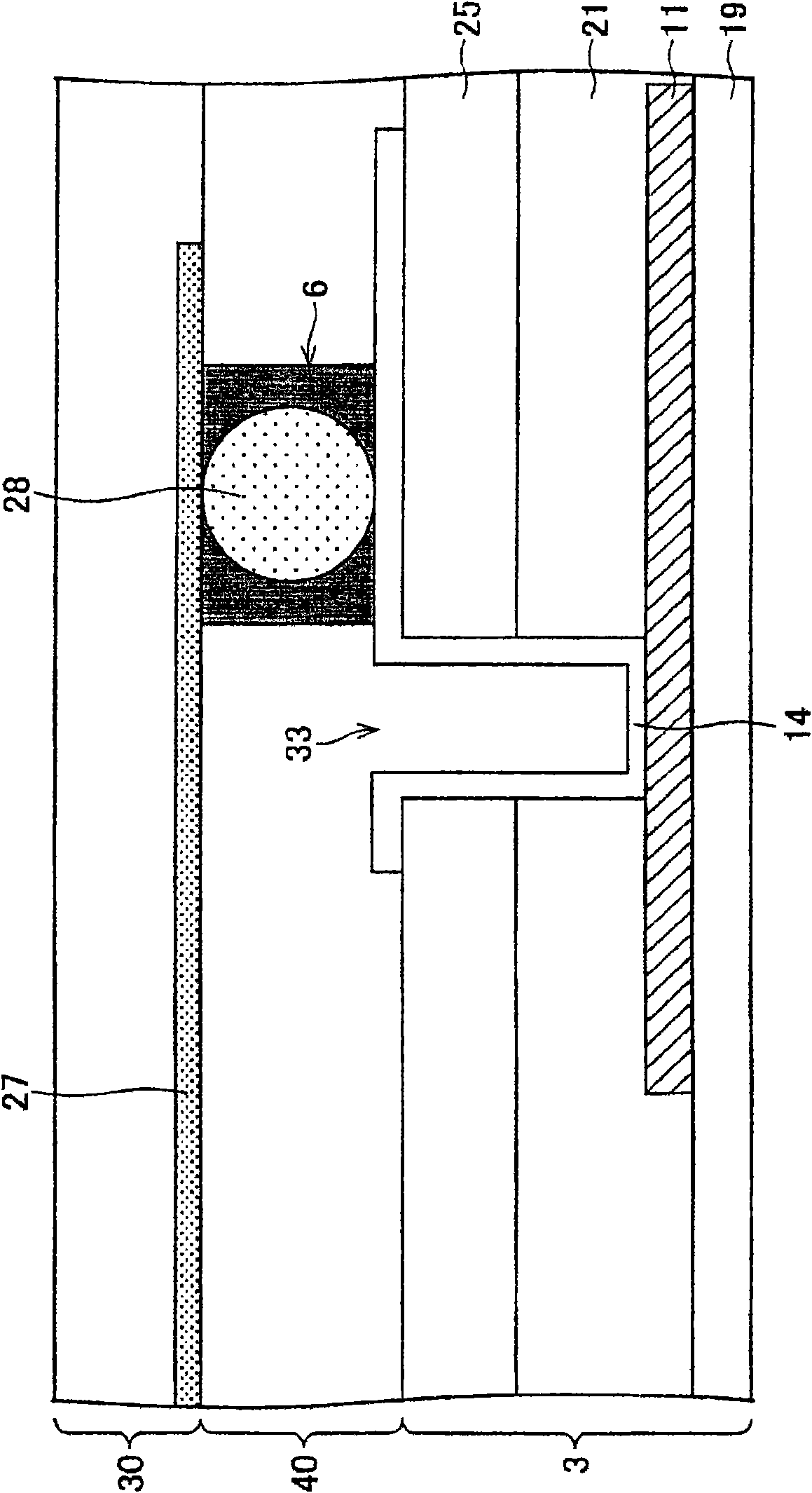

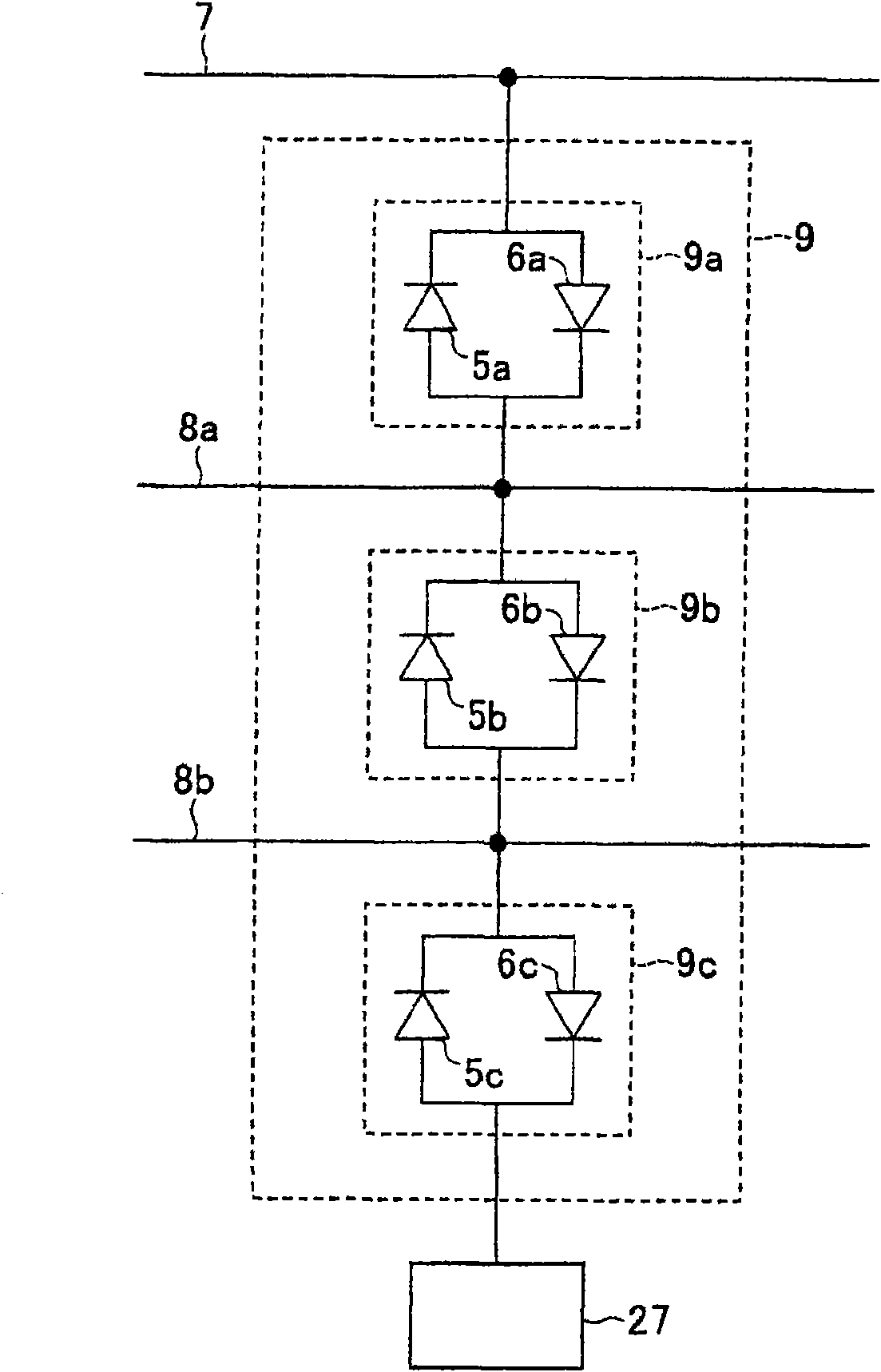

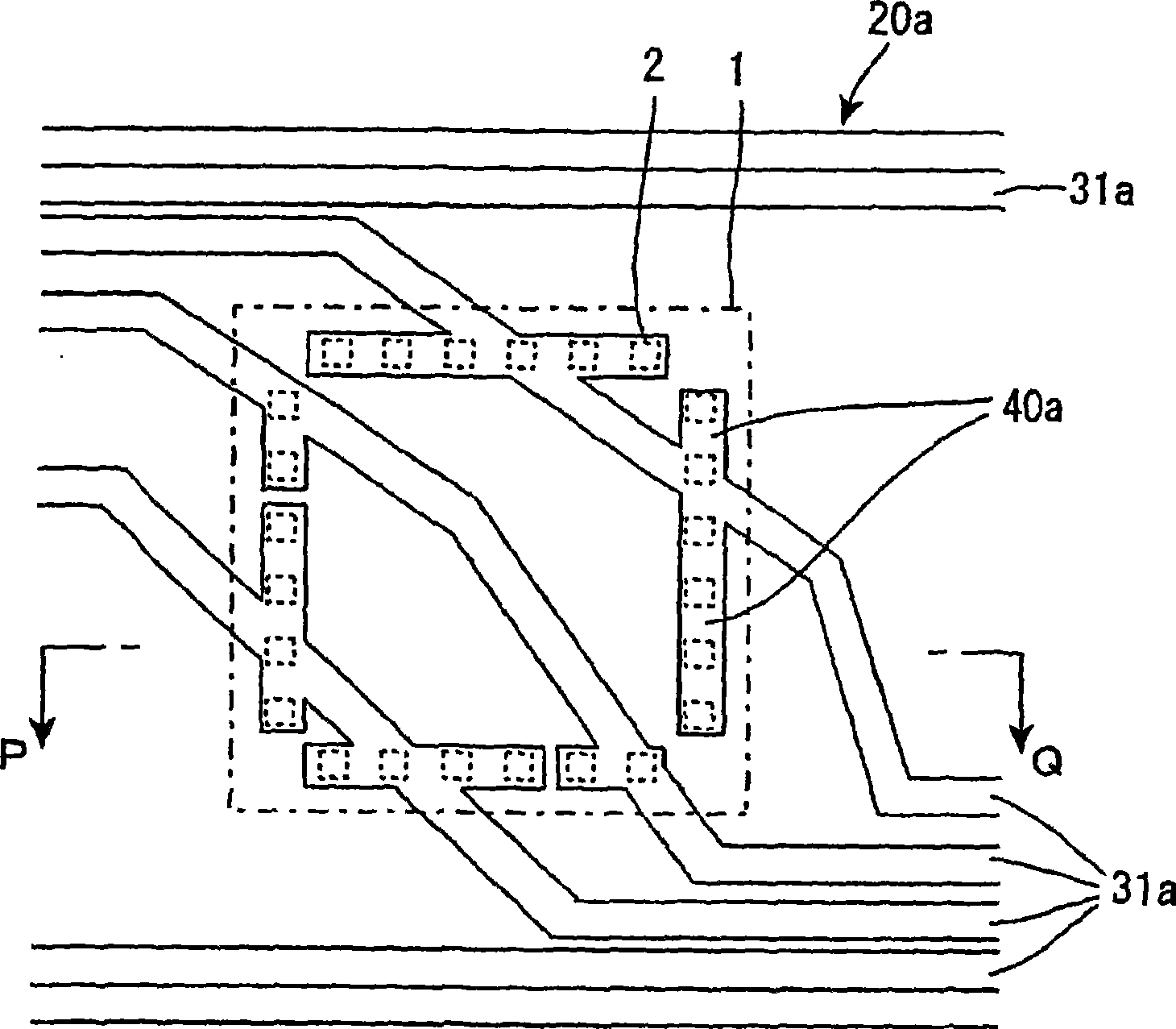

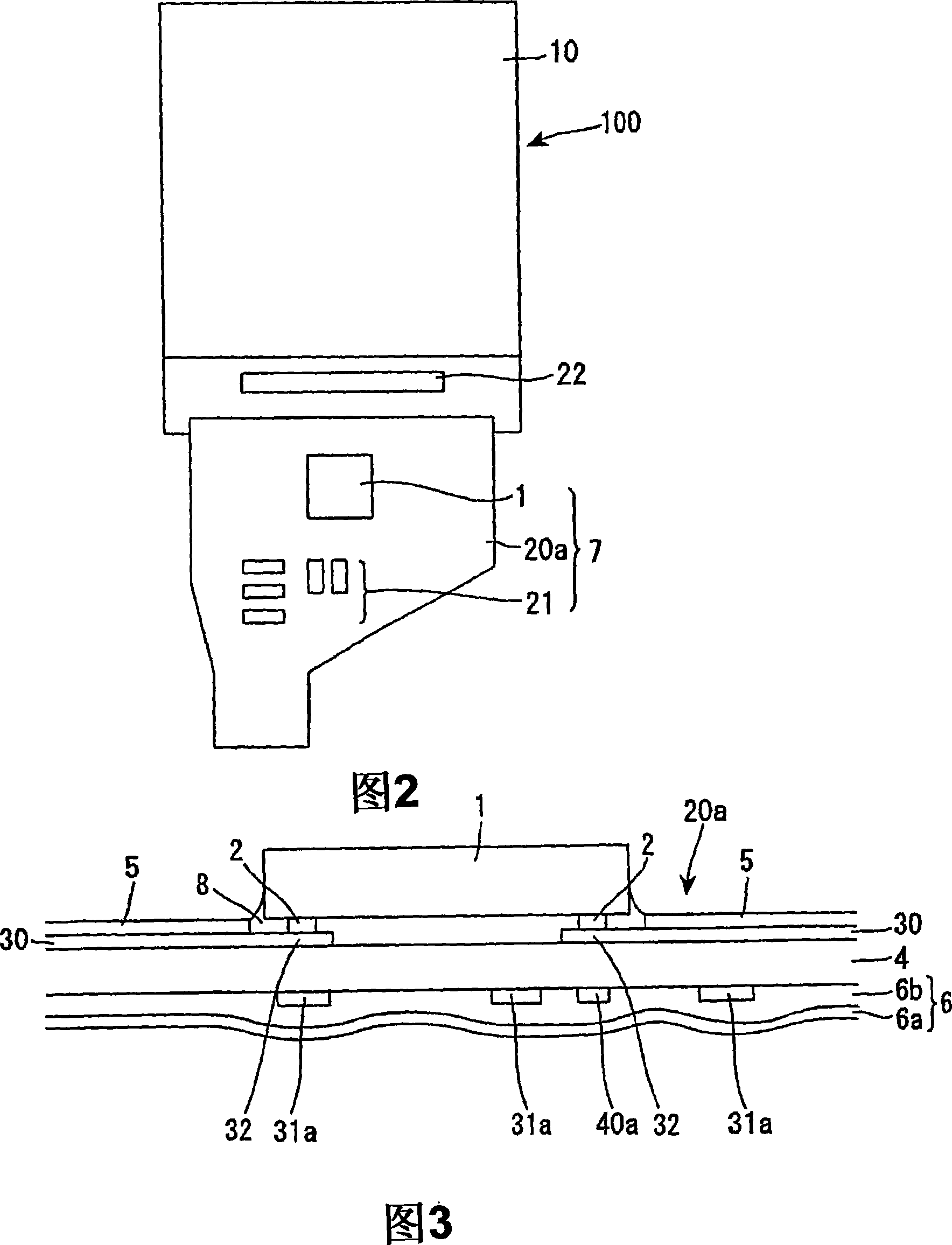

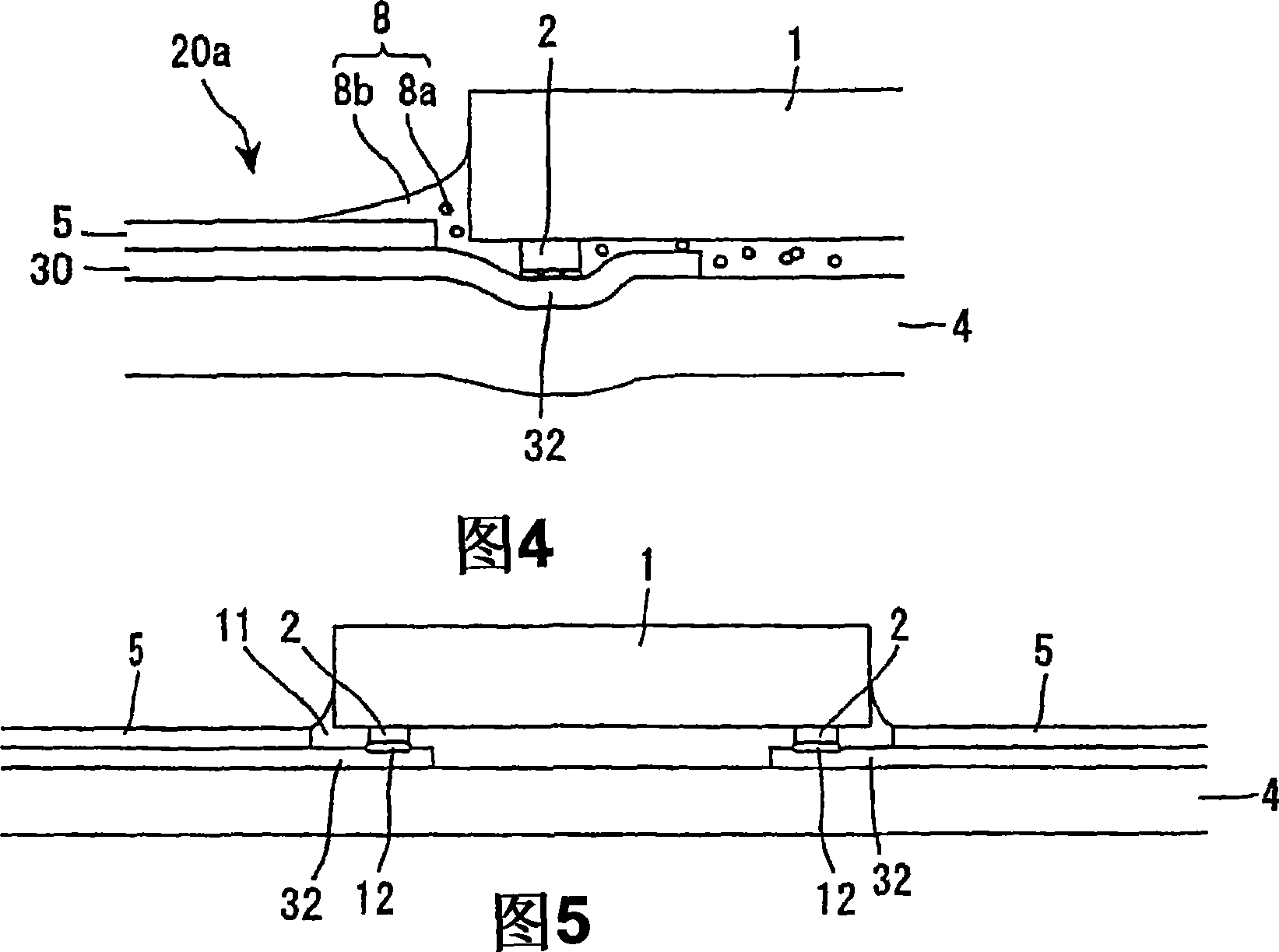

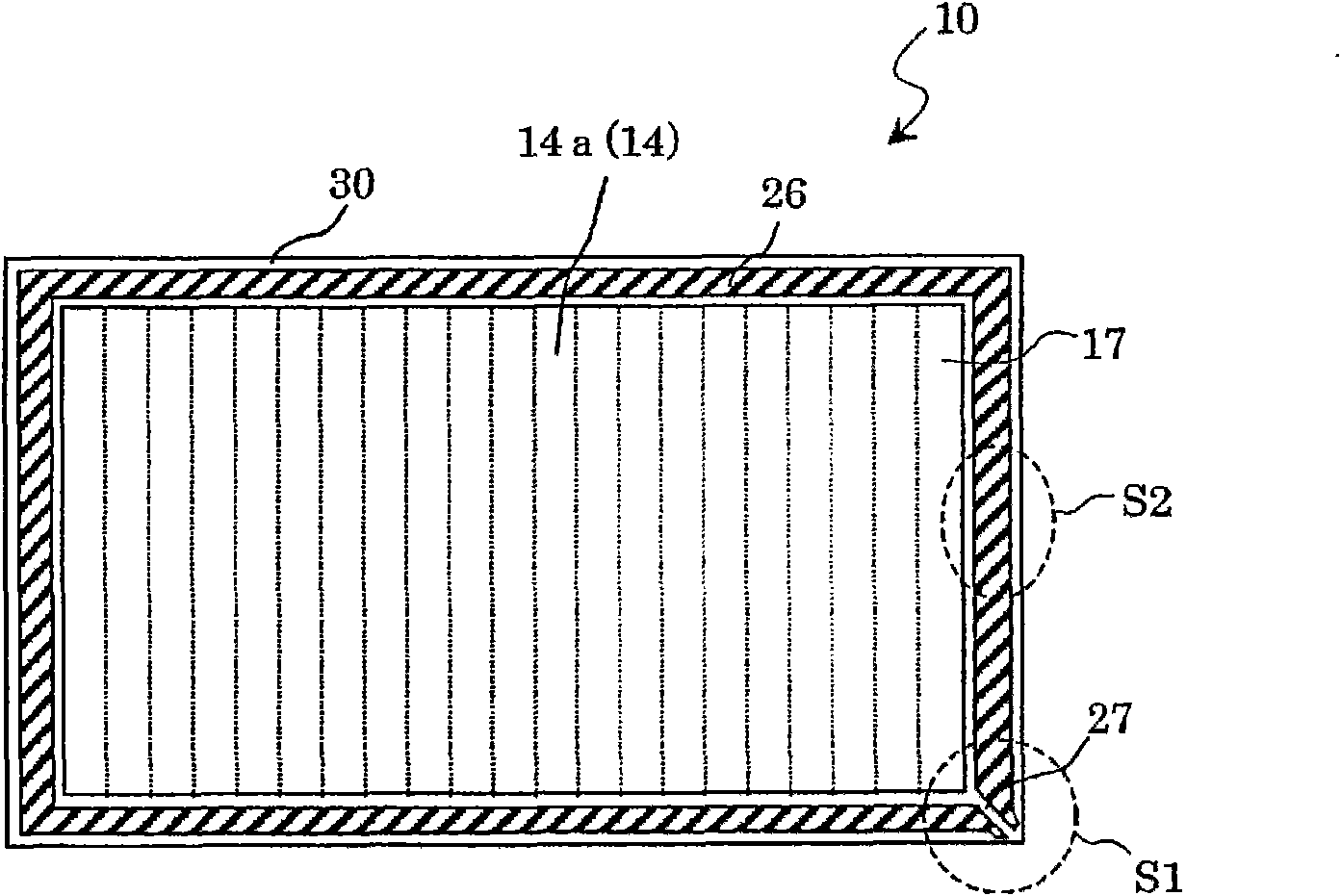

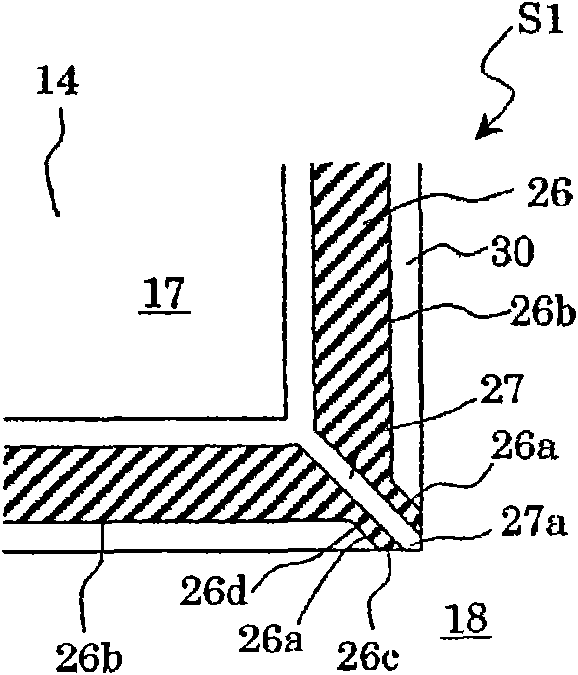

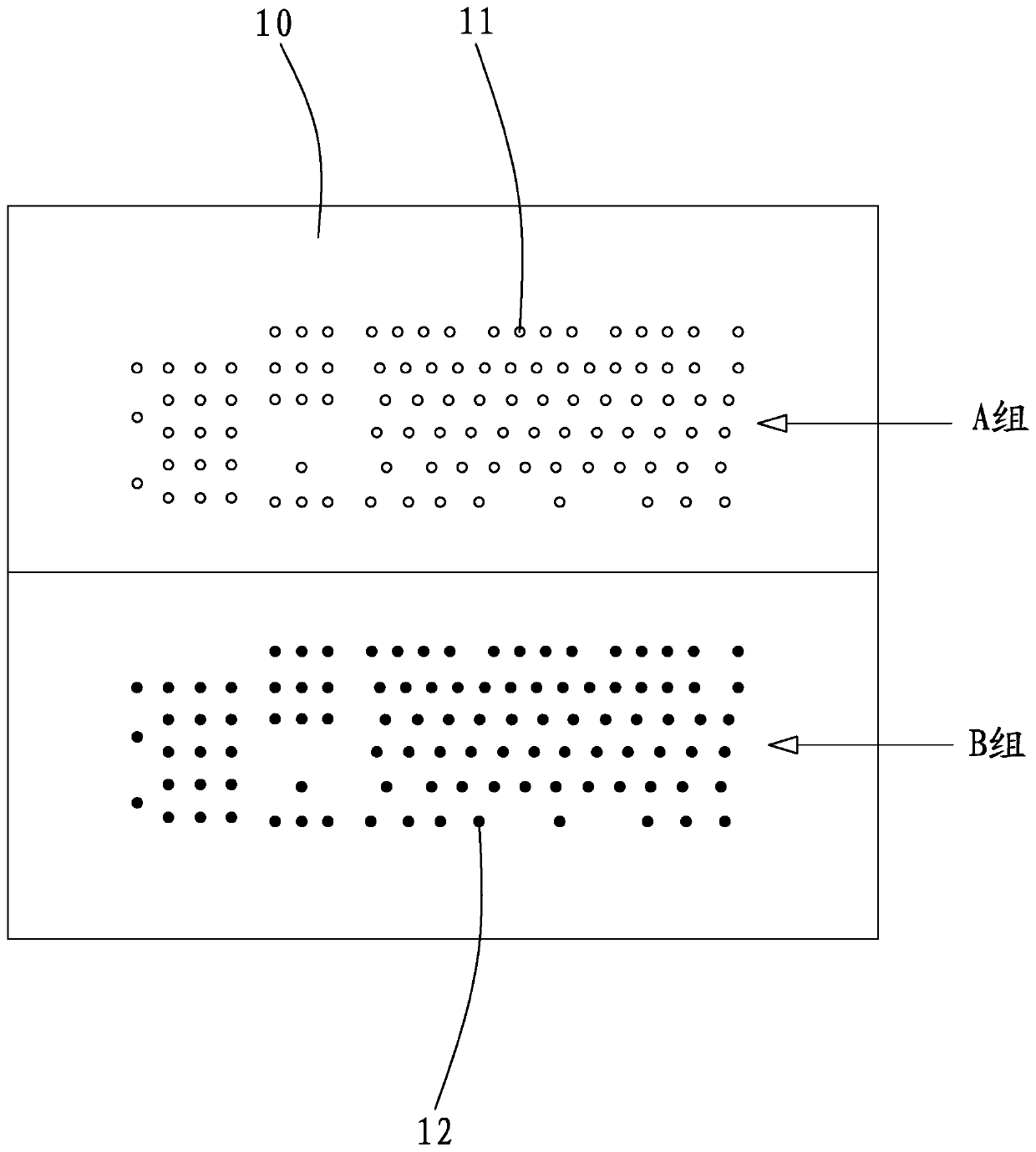

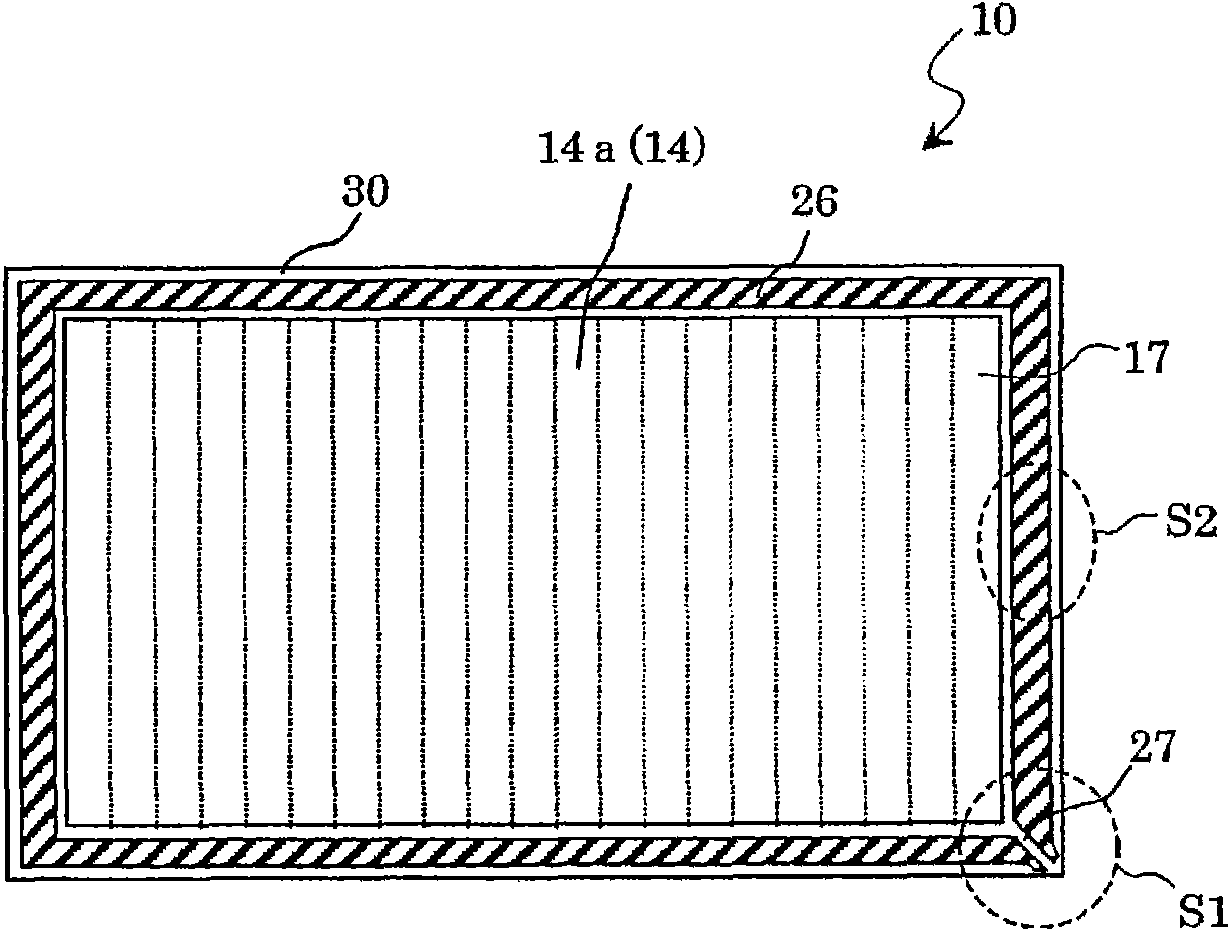

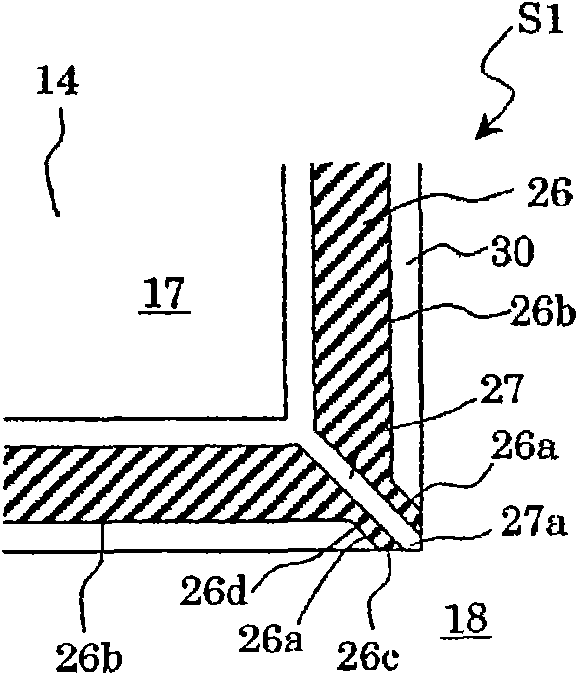

Liquid crystal panel, liquid crystal display device and television image receiver

InactiveCN101578551AReduce adverse conditionsTelevision system detailsColor television detailsElectricityActive matrix

A liquid crystal panel (10) is provided with an active matrix substrate whereupon a transistor (12), a pixel electrode (17), signal lines (15, 16) and backup wirings (8a, 8b) for modifying defects of the signal lines are formed; a color filter substrate whereupon a common electrode (counter electrode) is formed; and a liquid crystal material arranged between the both substrates. The backup wirings (8a, 8b) are (electrically) connected to the common electrode on the color filter substrate, through a protection circuit (9) for releasing undesired charges generated on the backup wirings (8a, 8b) and a seal (6). Problems (for instance, unexpected short-circuit of the backup wirings and the signal line) due to the undesired charges generated on the backup wirings can be reduced.

Owner:SHARP KK

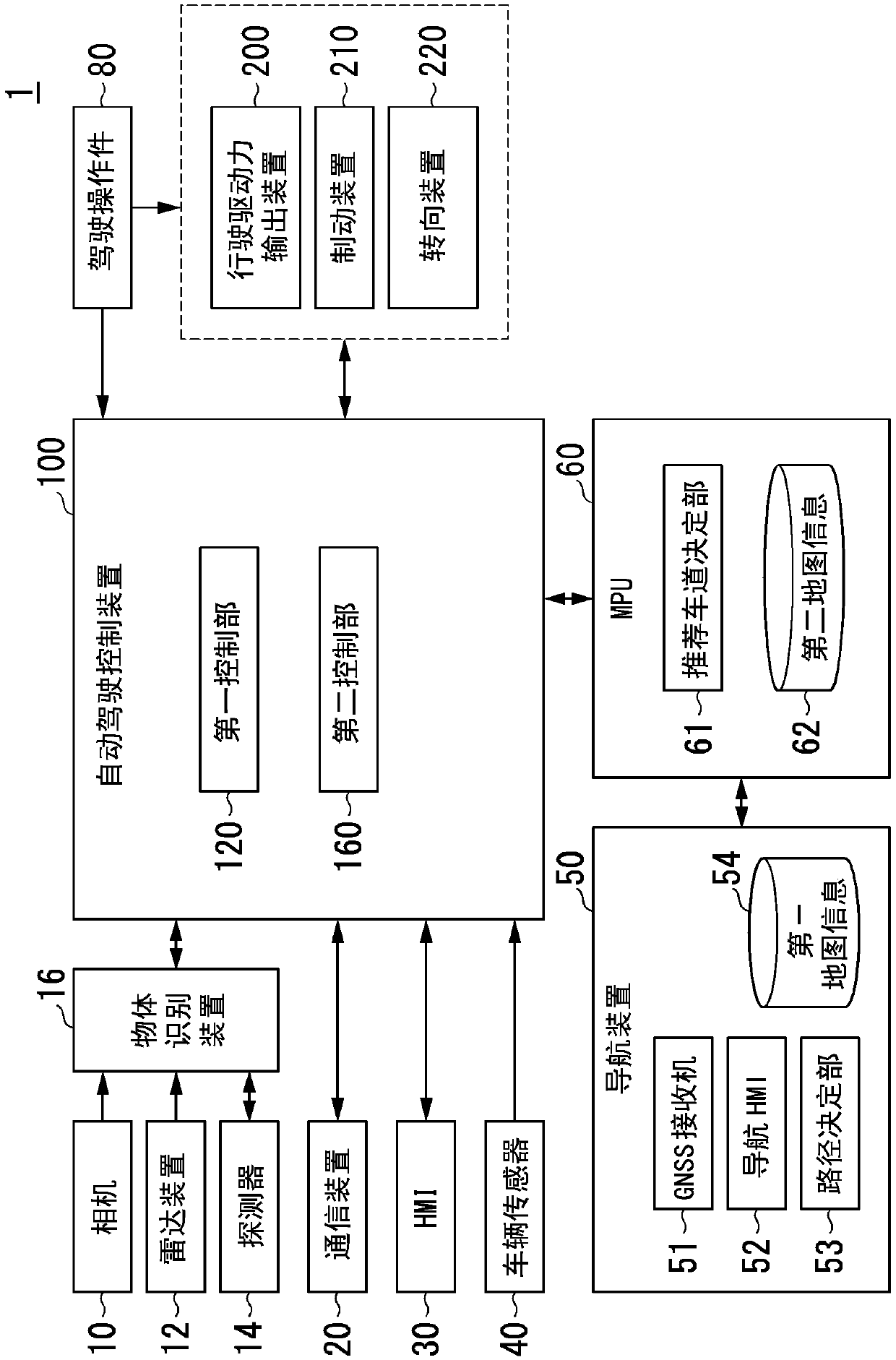

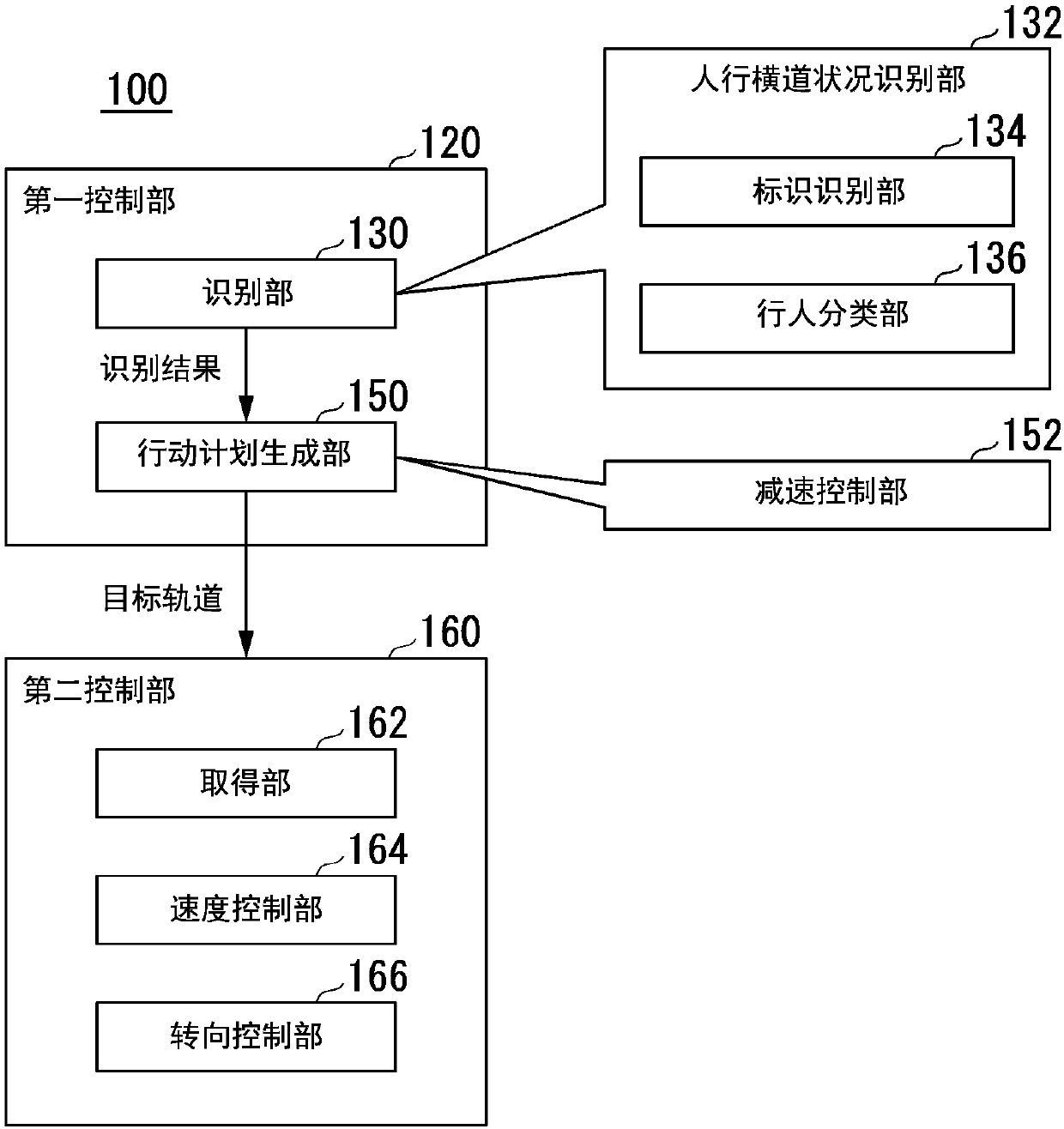

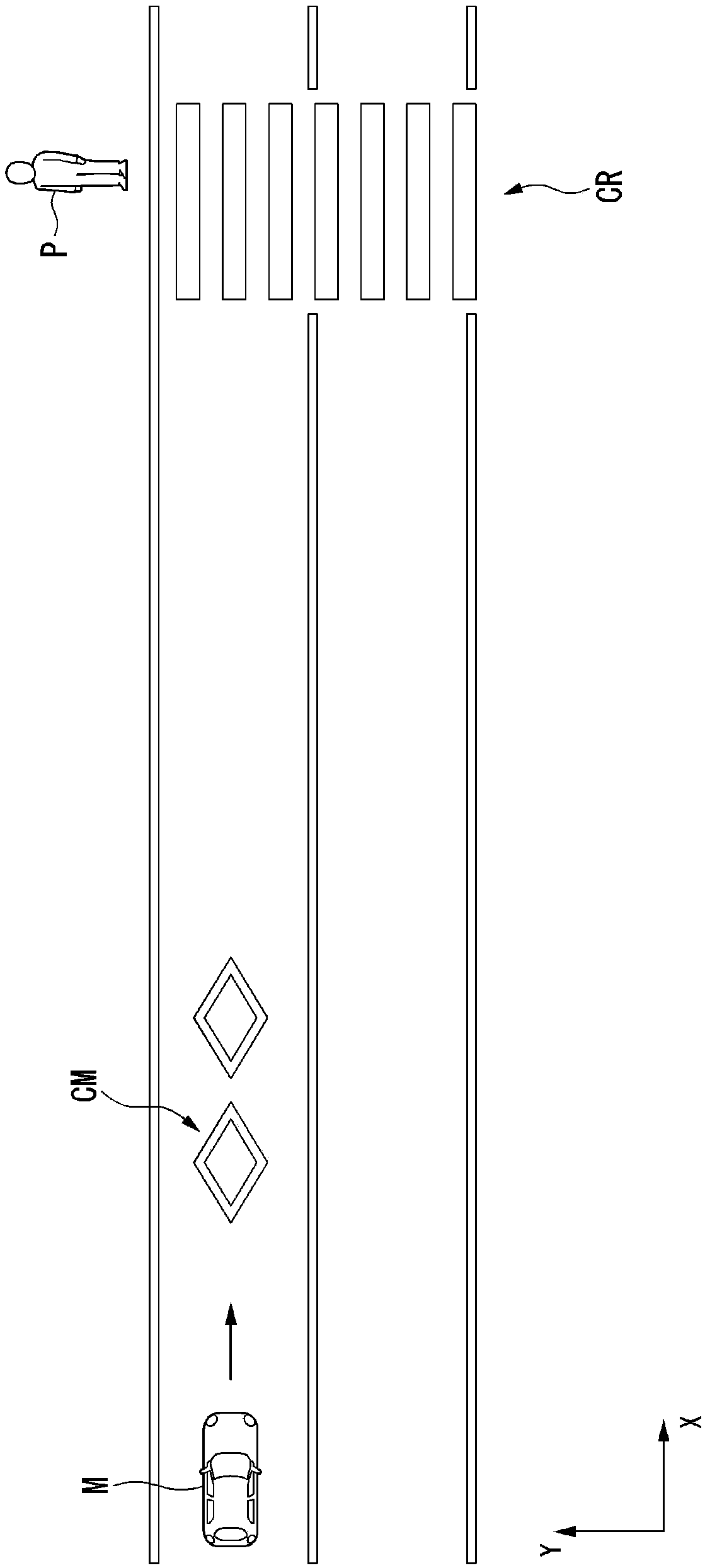

Vehicle control device, vehicle control method, and storage medium

InactiveCN109795462AAppropriate decelerationReduce speed variationAutonomous decision making processAutomatic initiationsVehicle controlAcceleration Unit

Owner:HONDA MOTOR CO LTD

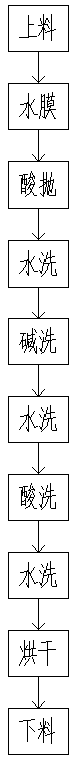

Method for solving problem of EL (electroluminescent) black spots of PERC (passivated emitter and rear cells)

InactiveCN109326684AInhibit sheddingRelieve stressFinal product manufactureSemiconductor/solid-state device manufacturingWater volumeBlack spot

The invention belongs to the field of solar cell manufacture, and particularly relates to a method for solving the problem of EL (electroluminescent) black spots of PERC (passivated emitter and rear cells). The method has the advantages that the aperture sizes of spray pins of water films are 0.8 mm, water film devices can slowly cover silicon wafers, the silicon wafer covering water spray pressures of the water films can be relieved, the silicon wafer laying pressures can be reduced, undesirable conditions that existing water films are splashed all around to contaminate existing surrounding silicon wafers can be effectively reduced on the premise that consistent water flow is guaranteed, and the problem of the EL black spots of the PERC can be effectively solved by the aid of the method;the pressures of the water film devices can be relieved, the problem of falling of existing spray pins of the existing water films can be effectively solved, the problem of long-time pinhole blockingcan be solved, over-etching due to insufficient water volumes can be prevented, equipment staffs only need to carry out irregular replacement and maintenance, and accordingly the time and labor can besaved; the problems of water film splashing, belt and silicon wafer contamination and etching contamination due to excessively high power and high pressures of the existing water films can be solved,the yield of efficient single crystals can be increased, the efficiency of the efficient single crystals can be improved, and the method has a broad application prospect.

Owner:SUZHOU RUNYANG PHOTOVOLTAIC TECH

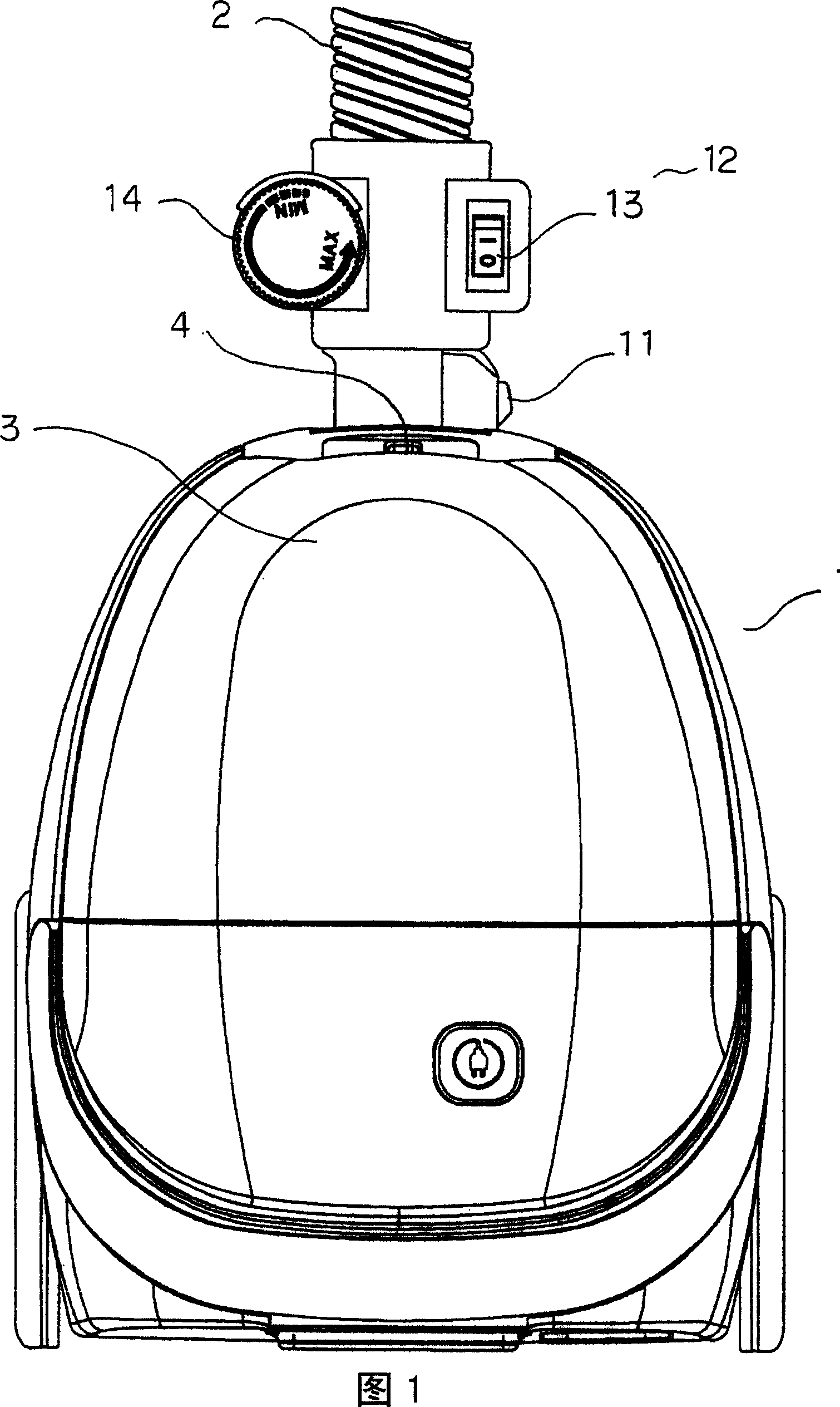

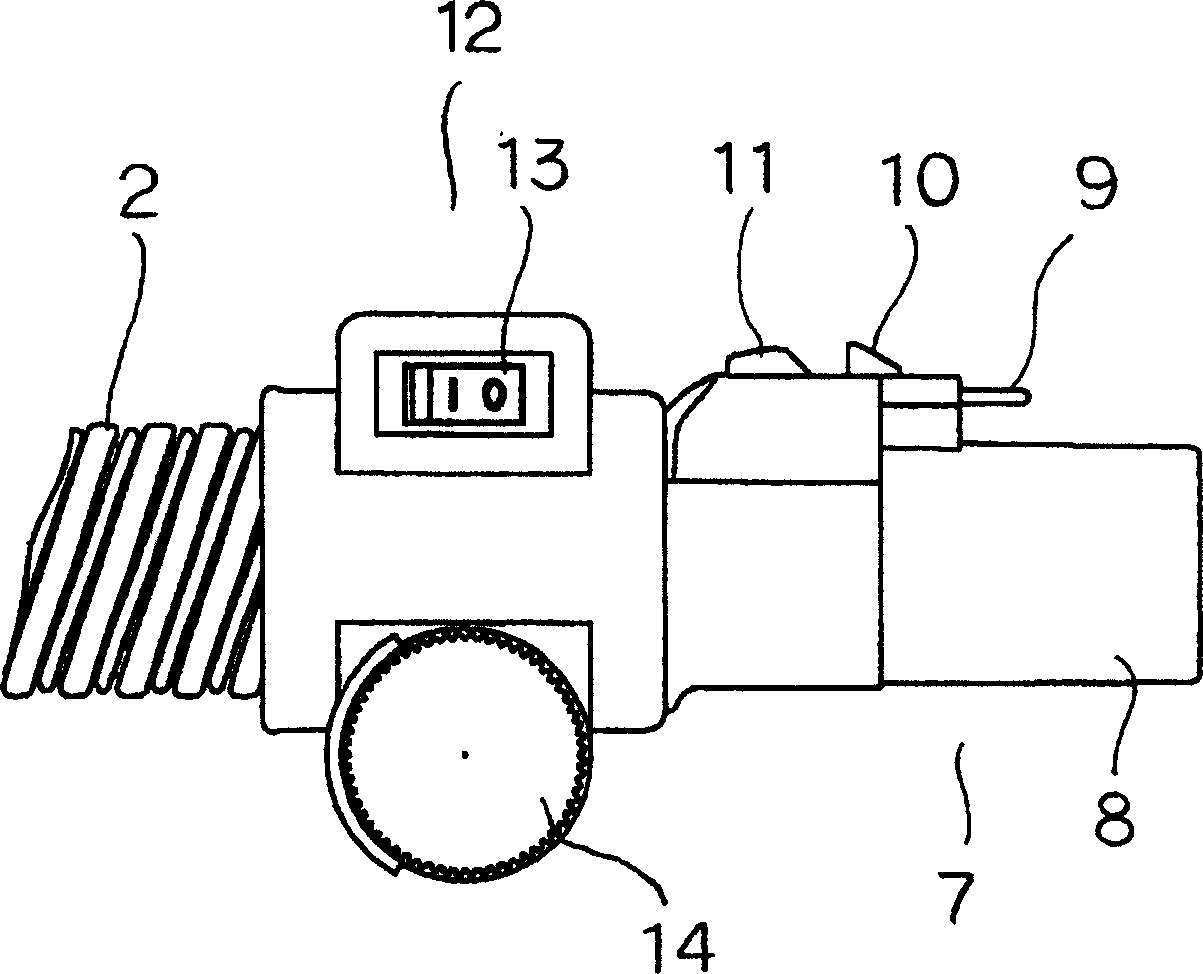

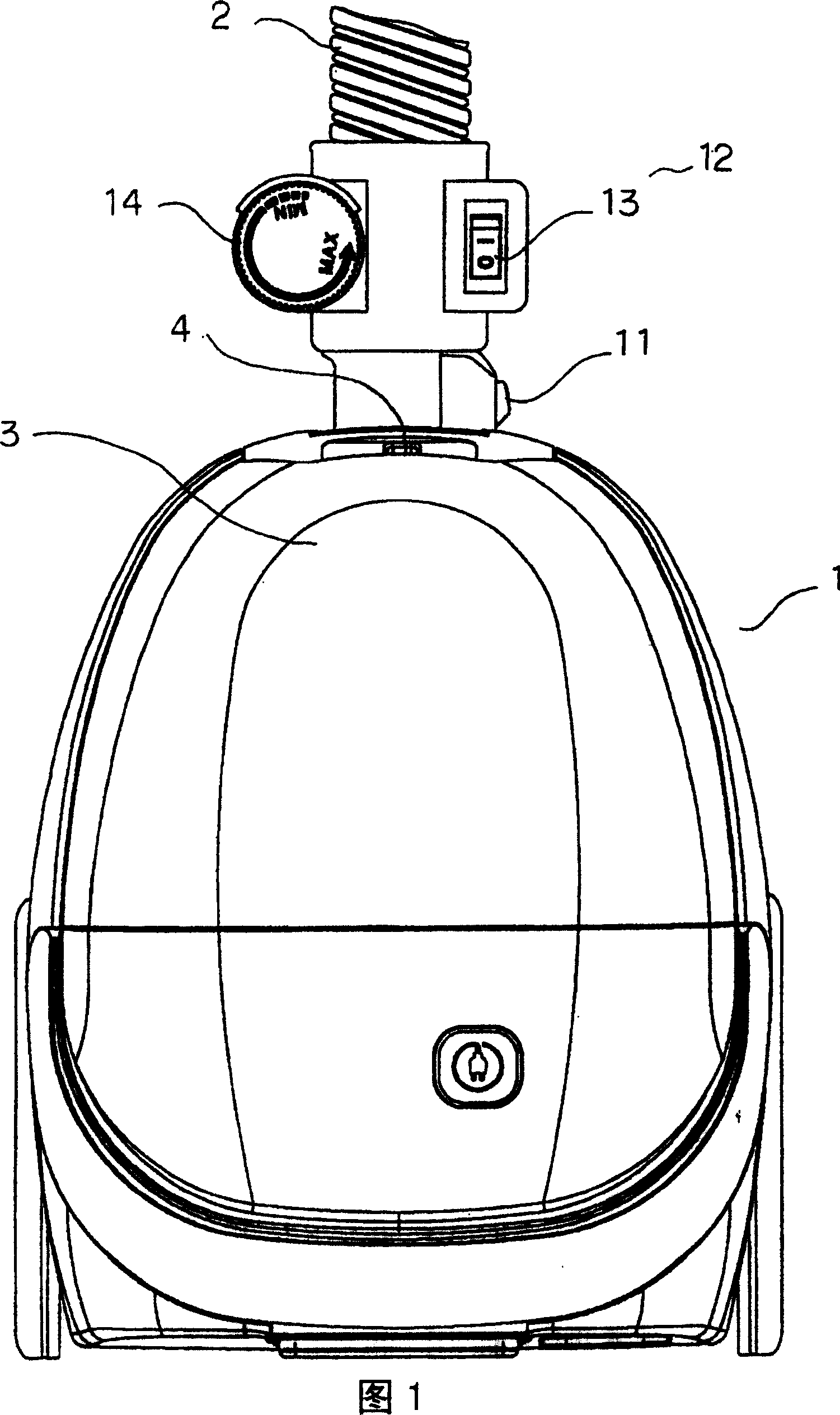

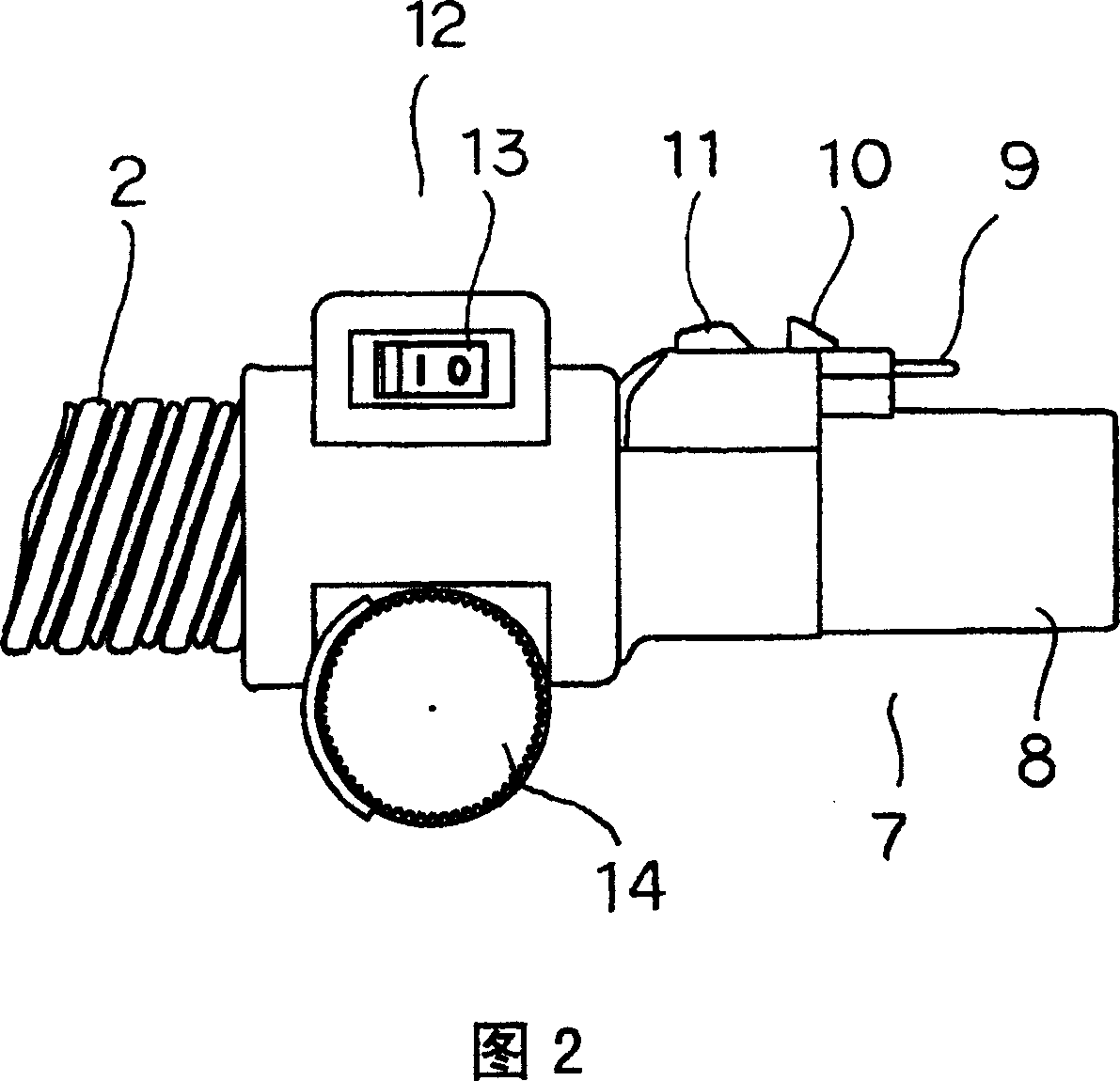

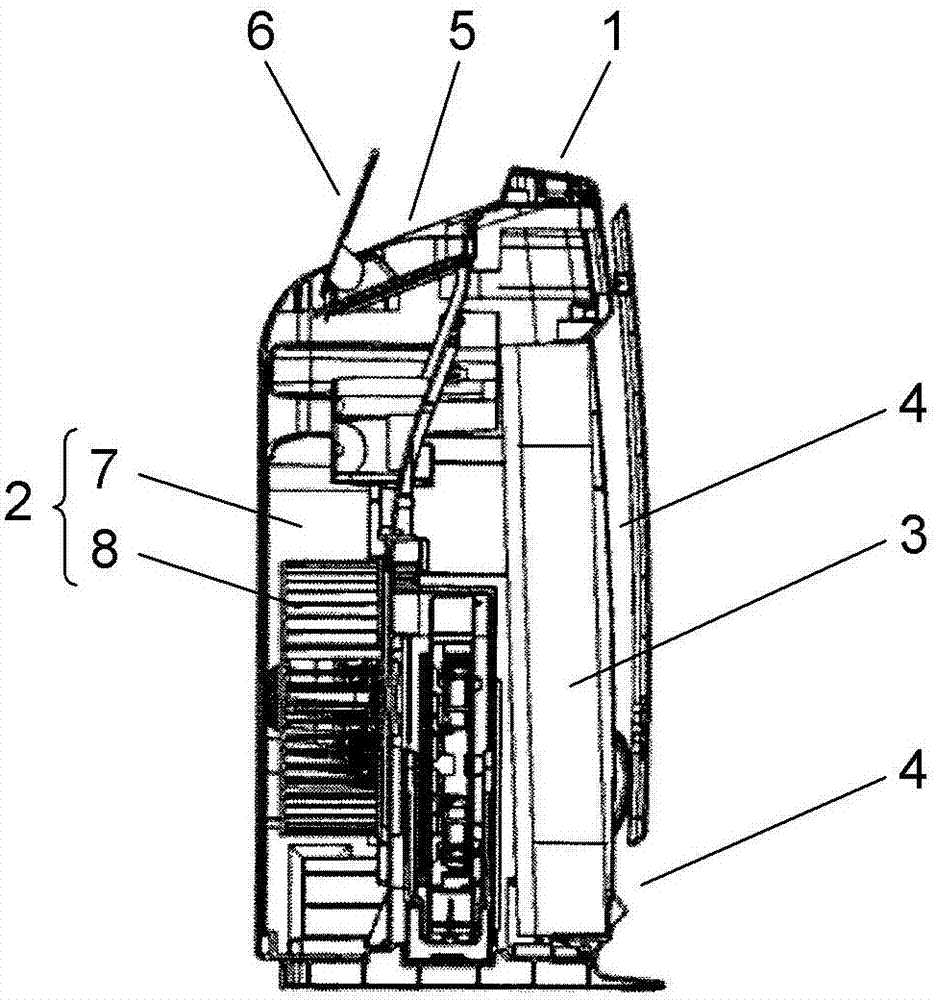

Electric dust collector

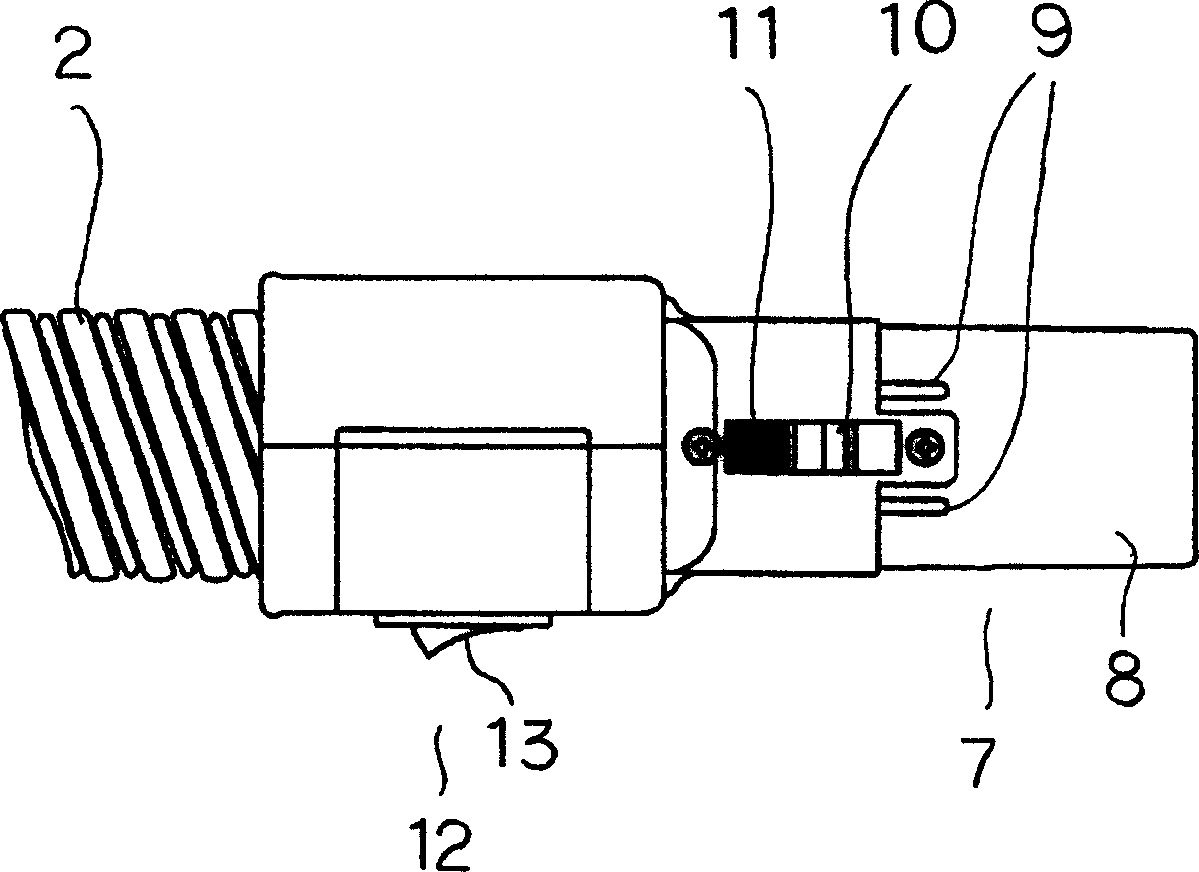

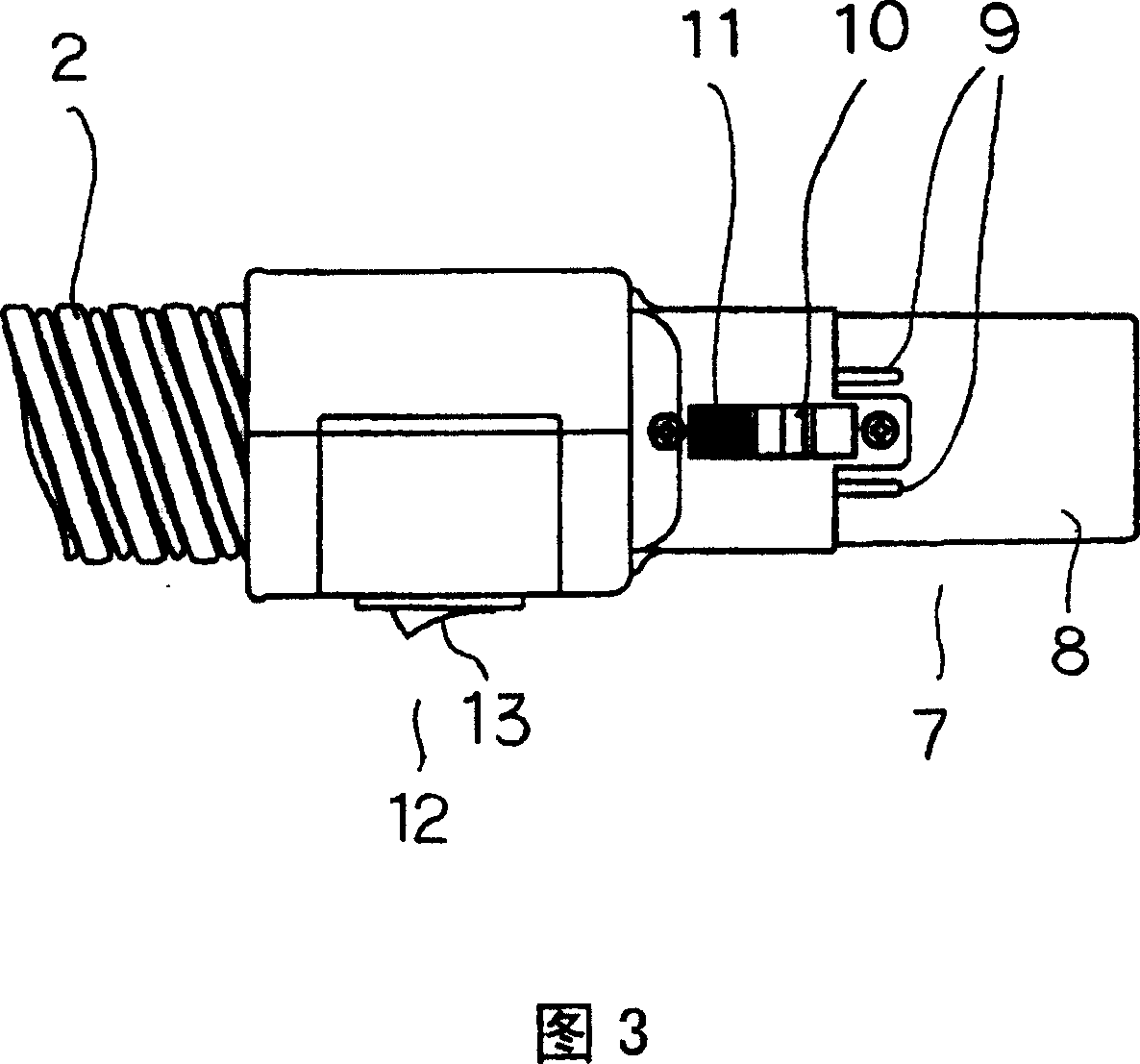

InactiveCN1663520AEasy to operateImprove management abilitySuction hosesSuction handlesEngineeringVacuum cleaner

Provided is a vacuum cleaner suppressing cost increase of a prevalent vacuum cleaner, withcommon use of a cleaner body both in the prevalent and high-grade vacuum cleaners, and reducing the labor in improving the productivity and in changing the design. The vacuum cleaner comprises the cleaner body with a dust collecting part and an electric blower, a hose 2 with one end detachably connected to the cleaner body 1 and the other end connected to one end of a pipe, and a floor brush connected to the other end of the pipe. In addition, a control part 12 for driving the electric blower is mounted near the end of the one end of the hose 2, and the control part 12 and the electric blower are electrically connected by attaching the hose 2 to the cleaner body 1.

Owner:SANYO ELECTRIC CO LTD

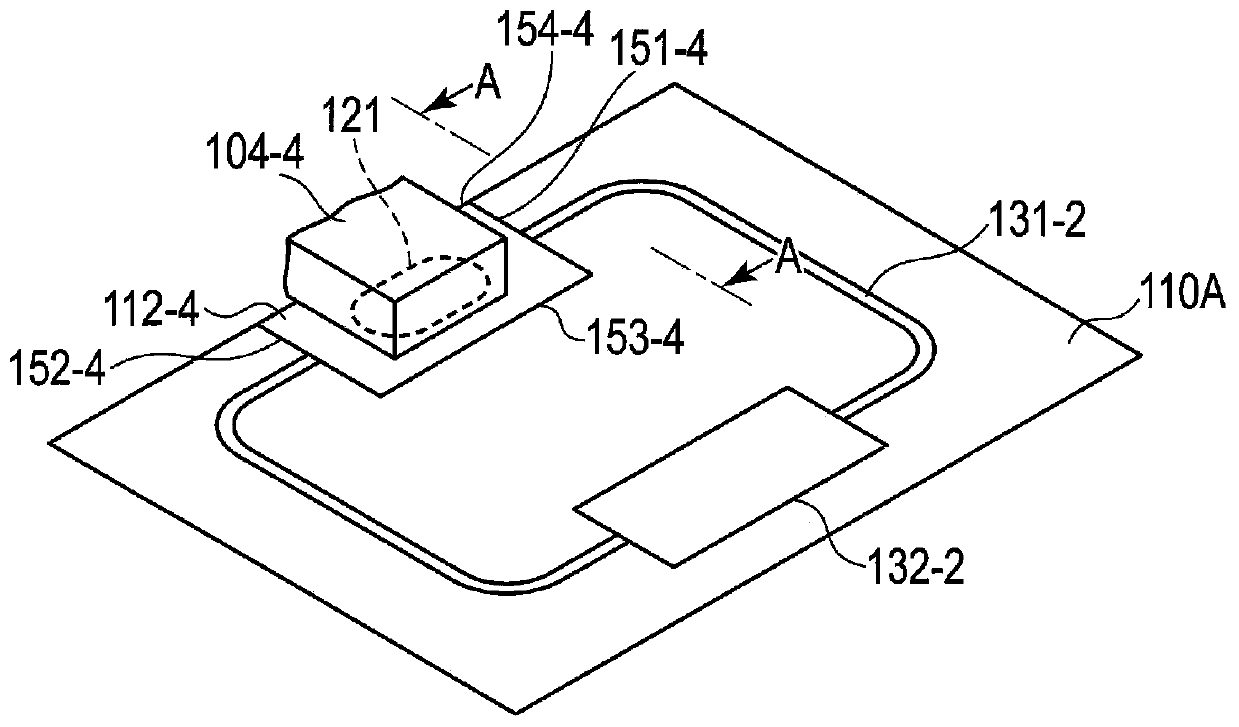

Circuit board, electronic circuit device, and display

ActiveCN101401496AReduce adverse conditionsMiniaturizationSemiconductor/solid-state device detailsPrinted circuit aspectsDisplay deviceEngineering

Owner:SHARP KK

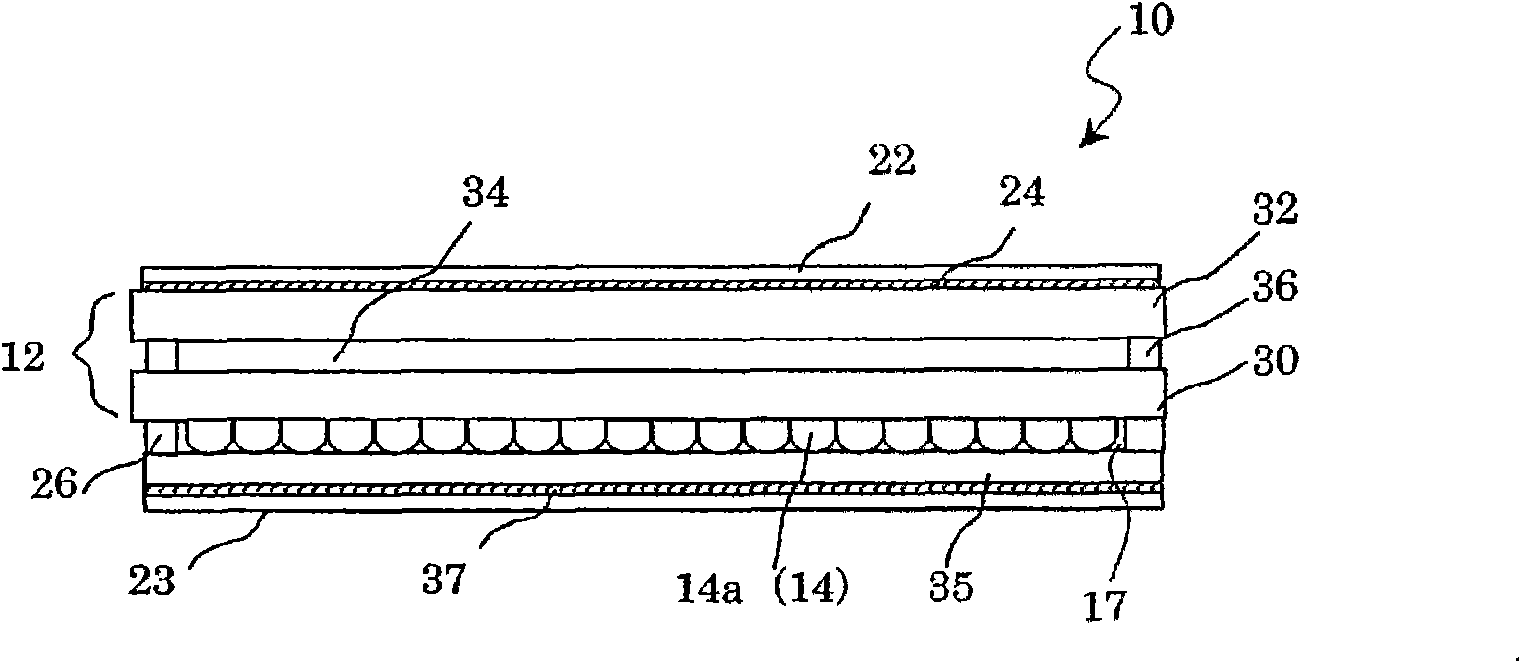

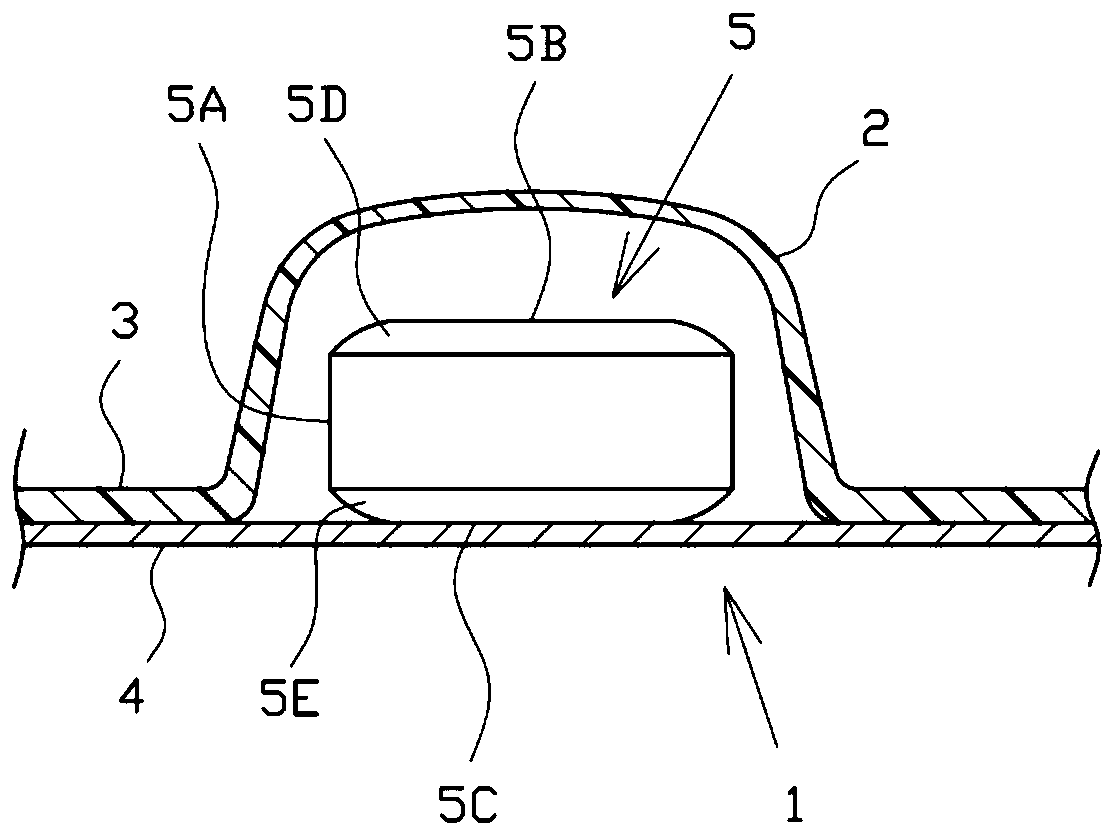

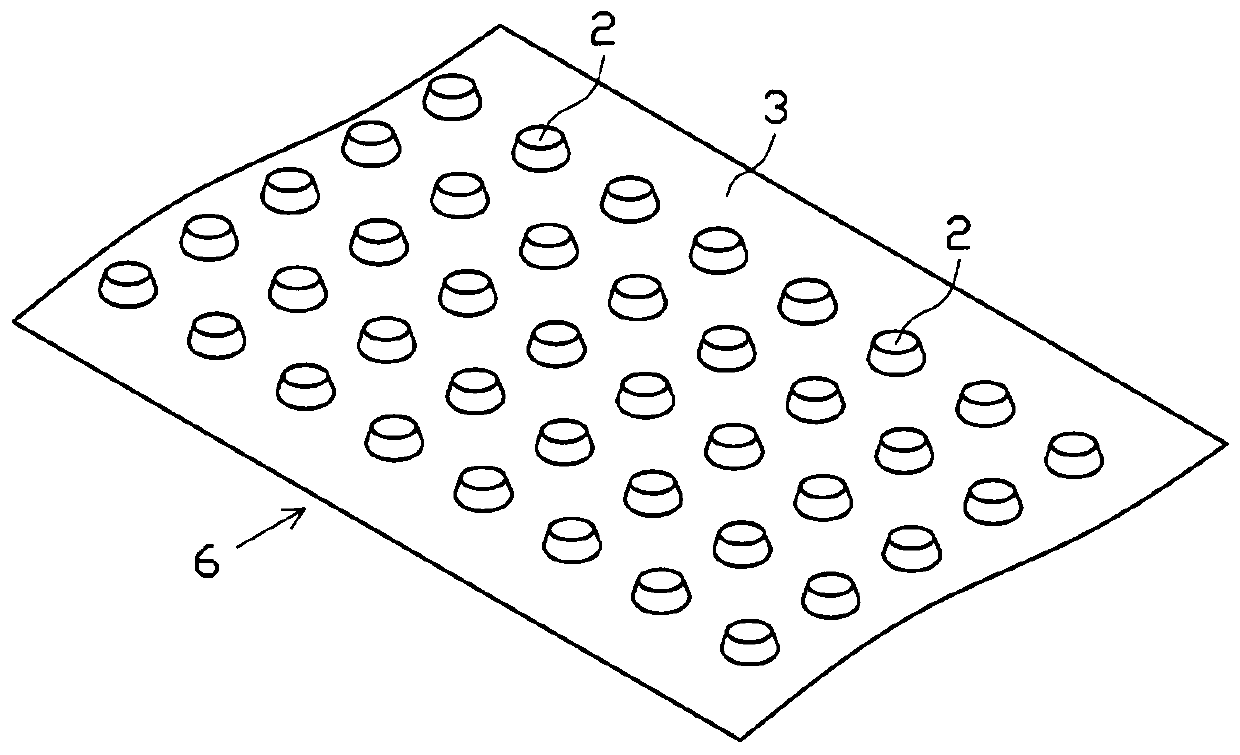

Liquid crystal display panel with microlens array and method for manufacturing the same

InactiveCN101641634APrevent intrusionShock suppressionNon-linear opticsLensLiquid-crystal displayMicro lens array

A highly reliable liquid crystal display panel in which such a trouble as mixture of foreign material is prevented. The reliable liquid crystal display panel comprises a bonded substrate including a pair of substrates and a liquid crystal layer arranged therebetween, a microlens array provided on the light incident side of the bonded substrate, a support provided on the light incident side of thebonded substrate to surround the microlens array, and an optical film attached to the bonded substrate through the support. The support has a portion projecting farther to the outer space side than the major surface of the outer surface of the support, and a vent connecting the inner space surrounded by the support and the outer space. The opening of the vent on the outer space side is formed in the projection.

Owner:SHARP KK

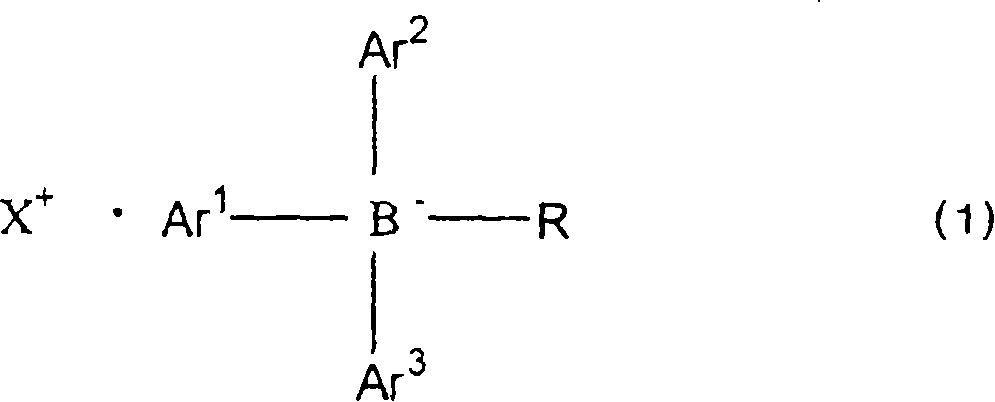

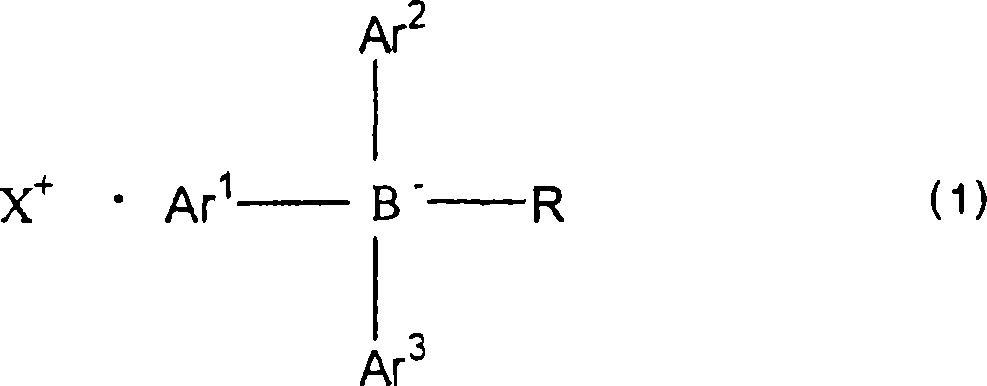

Pressure-sensitive adhesive having its adherence lost by actinic energy radiation, adhesive sheet having its adherence lost by actinic energy radiation obtained by application of the pressure-sensitiv

InactiveCN101031625AEtching resistantWill not dissolvePrinted circuit aspectsOrganic non-macromolecular adhesiveEtchingMetal foil

A pressure-sensitive adhesive having its adherence lost by actinic energy radiation, comprising an etching-resistant photopolymerization initiator, an actinic energy radiation reactive compound and a hardening agent. Further, there is provided a process for producing an etched metallic material, comprising the steps of: (1) adhering a metal foil to a base film by means of the above pressure-sensitive adhesive having its adherence lost by actinic energy radiation; (2) performing selective etching of the metal foil to thereby obtain an etched metal layer; (3) combining the etched metal layer of the laminate composed of the base film, pressure-sensitive adhesive having its adherence lost by actinic energy radiation and etched metal layer with an insulating substrate; and (4) detaching the base film from the etched metal layer, wherein exposure to actinic energy radiation is carried out at least once after the step (1) but prior to the step (4).

Owner:TOYO INK SC HOLD CO LTD

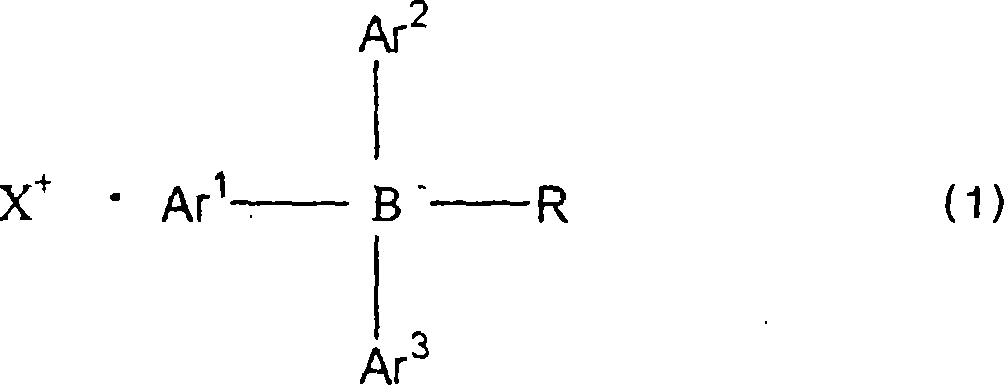

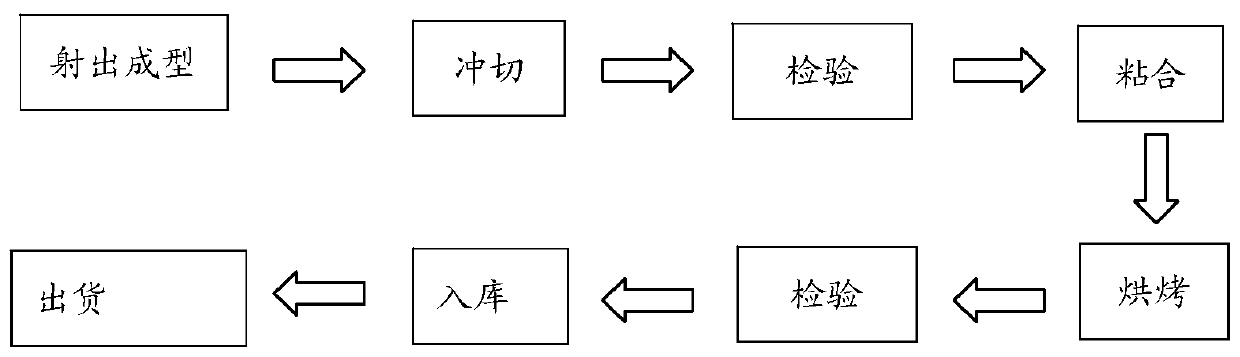

Production process of circuit board with silicone keys

InactiveCN109920680ASavingsAssembly positioning is accurateElectric switchesPunchingFlexible circuits

The invention discloses a production process of a circuit board with silicone keys. The production process comprises the steps of injection molding of the silicone keys, gluing of a flexible circuit board, fitting molding of the silicone keys and the flexible circuit board, discharging inspection and warehousing. Compared with the prior art, the production process of the circuit board with the silicone keys provided by the invention has the advantages that the steps of opening a punching die, forming a bonding assembly line and a bonding jig, baking and the like are omitted; the injection molding step and the fitting molding step can be completed on a same molding die at the same time, so that the product manufacturing time is greatly saved, adverse conditions are reduced, the equipment investment of corresponding steps is saved, and the product production cost is greatly reduced.

Owner:INJECTION PRECISION RUBBER SUZHOU CO LTD

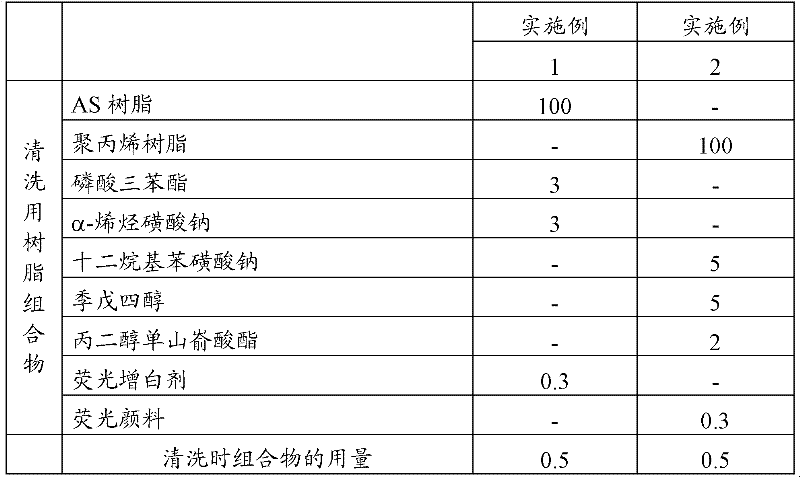

Resin composition for cleaning of resin molding machines

InactiveCN102333627AShorten cleaning timeReduce adverse conditionsOrganic detergent compounding agentsDetergent dyesMolding machineInjection molding machine

A resin molding machine is cleaned using a resin composition for cleaning of resin molding machines, said resin composition for cleaning of resin molding machines containing a thermoplastic resin and a fluorescent tracer substance. After cleaning the resin molding machine, which has been performed a molding process of a resin, using the resin composition for cleaning, the resin composition for cleaning remaining in the resin molding machine after the cleaning is extruded and removed therefrom by a molding resin used in the succeeding molding process. In the extrusion and removal step of the resin composition for cleaning, after a molded body is obtained from the molding resin used in the succeeding molding process, the presence or absence of a residue of the resin composition for cleaning can be determined by checking the presence or absence of fluorescence in the surface of the molded body.

Owner:DAICEL POLYMER LTD

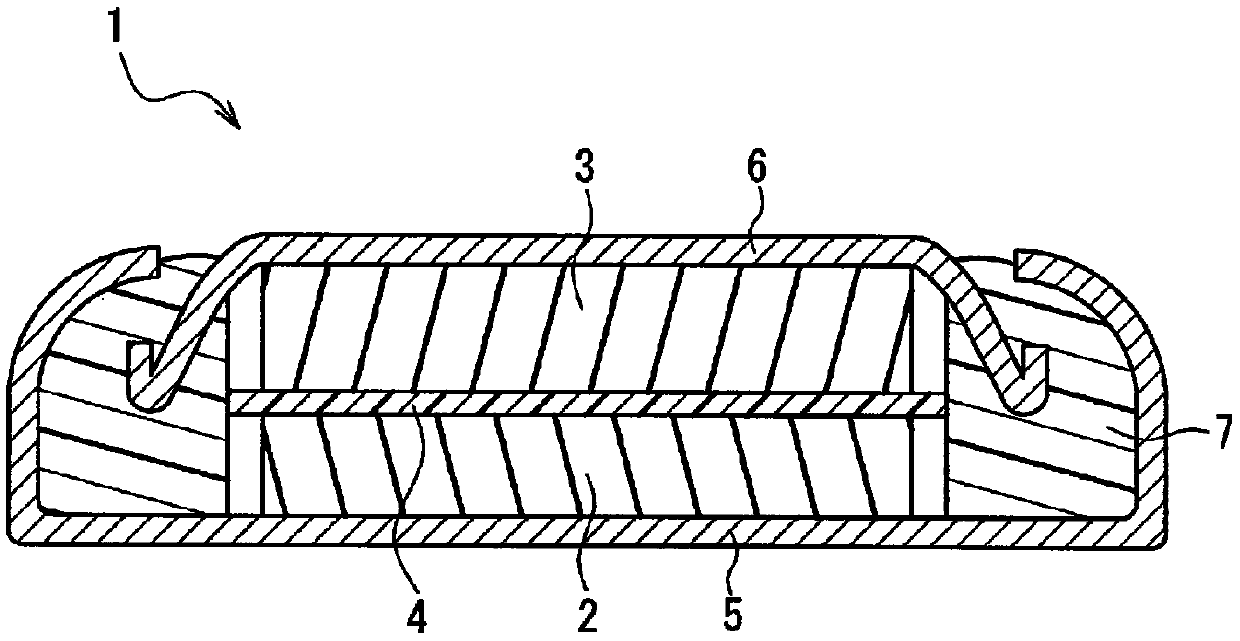

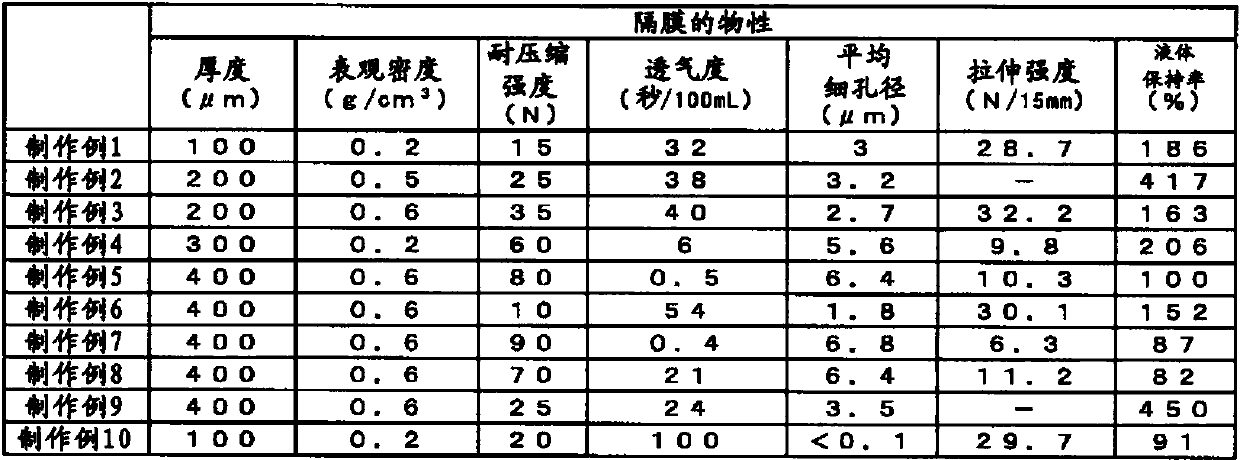

Separator and non-aqueous electrolyte battery

InactiveCN109690823ASuppresses characteristic deteriorationReduce adverse conditionsHybrid capacitor separatorsPaper/cardboardElectrolytic agentElectrical battery

This non-aqueous electrolyte battery is provided with: a positive electrode; a negative electrode; a separator; and a non-aqueous electrolyte, wherein the separator includes 50-85 mass% of a polyphenylene sulfide fiber, 10-30 mass% of an aramid fiber, and 5-35 mass% of a cellulose fiber. Thereby, the present invention can provide a non-aqueous electrolyte battery in which degradation in propertiesin a high-temperature environment is suppressed and defects during assembling less occurs.

Owner:MAXELL HLDG LTD +1

Sanitary napkin small-bag triple-folding process

InactiveCN105943249AFit tightlyImprove stabilityFolding thin materialsSanitary towelsSurface layerEngineering

The invention relates to the field of disposable hygiene products, in particular to a sanitary napkin small-bag triple-folding process. The process comprises the following steps: the first step: combining a cotton core, a surface layer and a bottom layer, so that a continuous sanitary napkin combination in a strip-shaped form is formed, and then covering the sanitary napkin combination with a small covering film by virtue of a covering mechanism; the second step: after covering with the small covering film, heat-sealing and sticking two ends of various sanitary napkins by virtue of a heat-sealing device, and then cutting off the sanitary napkin combination, so that independent sanitary napkin products are formed; the third step: turning the independent sanitary napkin products by 90 degrees; and the fourth step: folding the independent sanitary napkin products in a triple-folding mechanism.

Owner:QUANZHOU HANWEI MACHINERY MFG

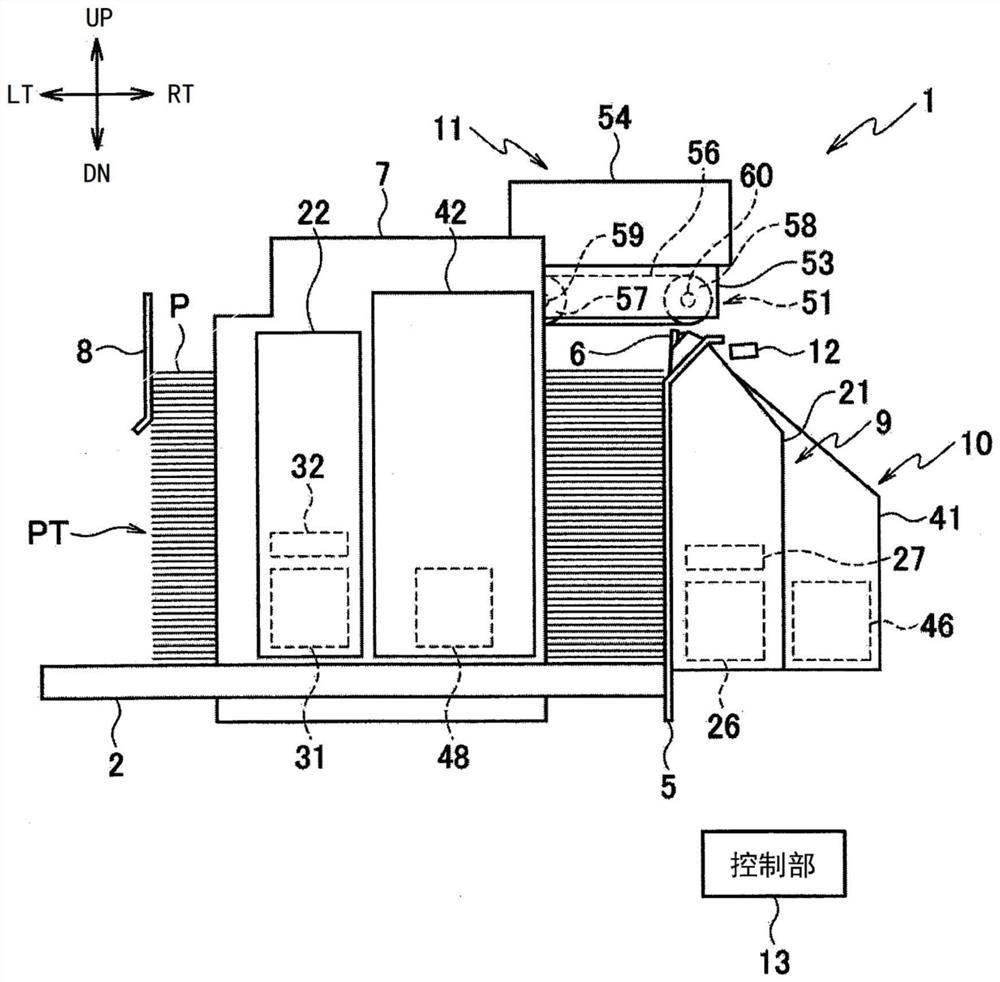

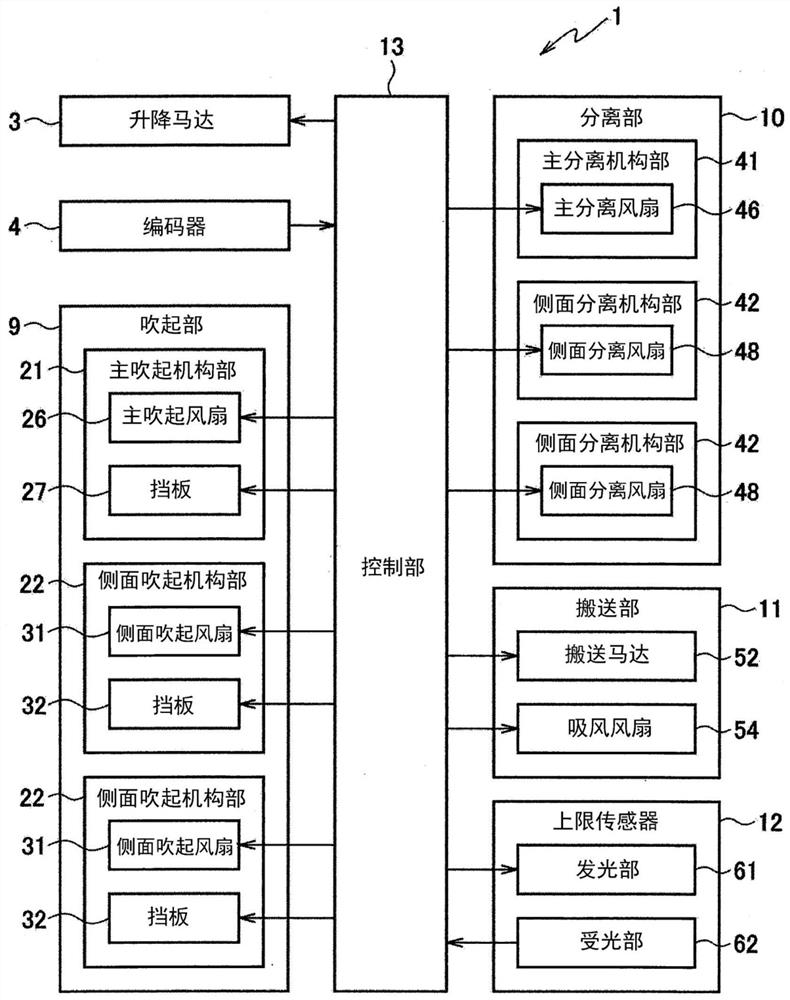

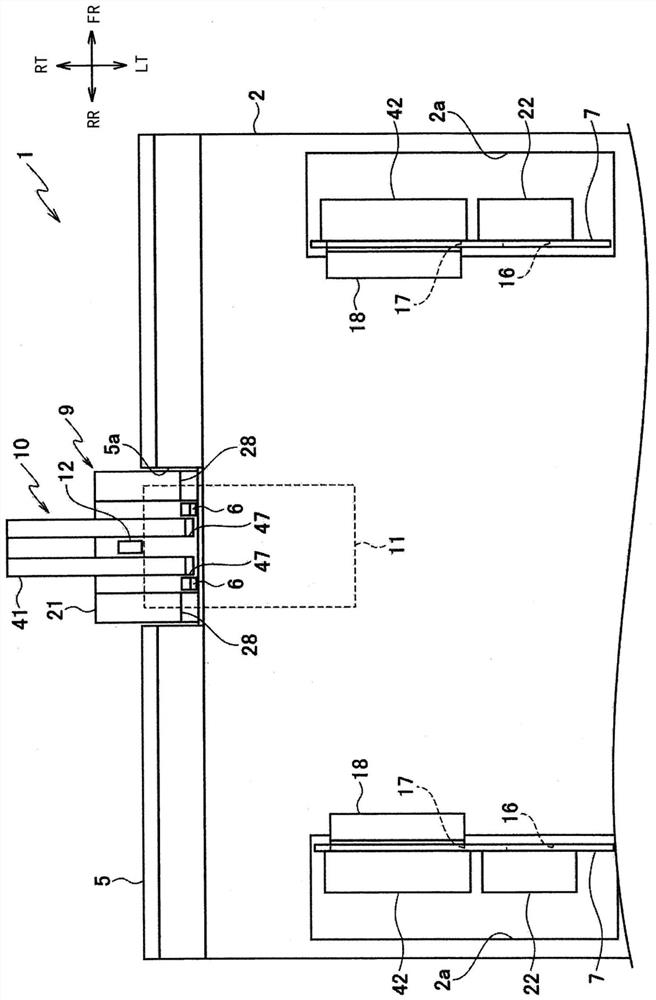

Sheet feeding device

ActiveCN113387203AReduce adverse conditionsArticle feedersArticle separationControl engineeringElectrical and Electronics engineering

The invention provides a sheet feeding device. A controller drives a floating unit and a conveyor to perform a sheet feed operation, during which the following tracking control is performed: acquiring an amount of received light at a detector during floating of sheets floated by the floating unit each time each sheet is conveyed by the conveyor, and lifting a stacking tray upon the acquired amount of received light being less than a threshold value. The controller, after start of the sheet feed operation, samples amounts of received light at the detector during floating of the sheets floated by the floating unit, performs a threshold value determination process of determining the threshold value by using the sampled amounts of received light, and starts the following control upon determining the threshold value.

Owner:RISO KAGAKU CORP

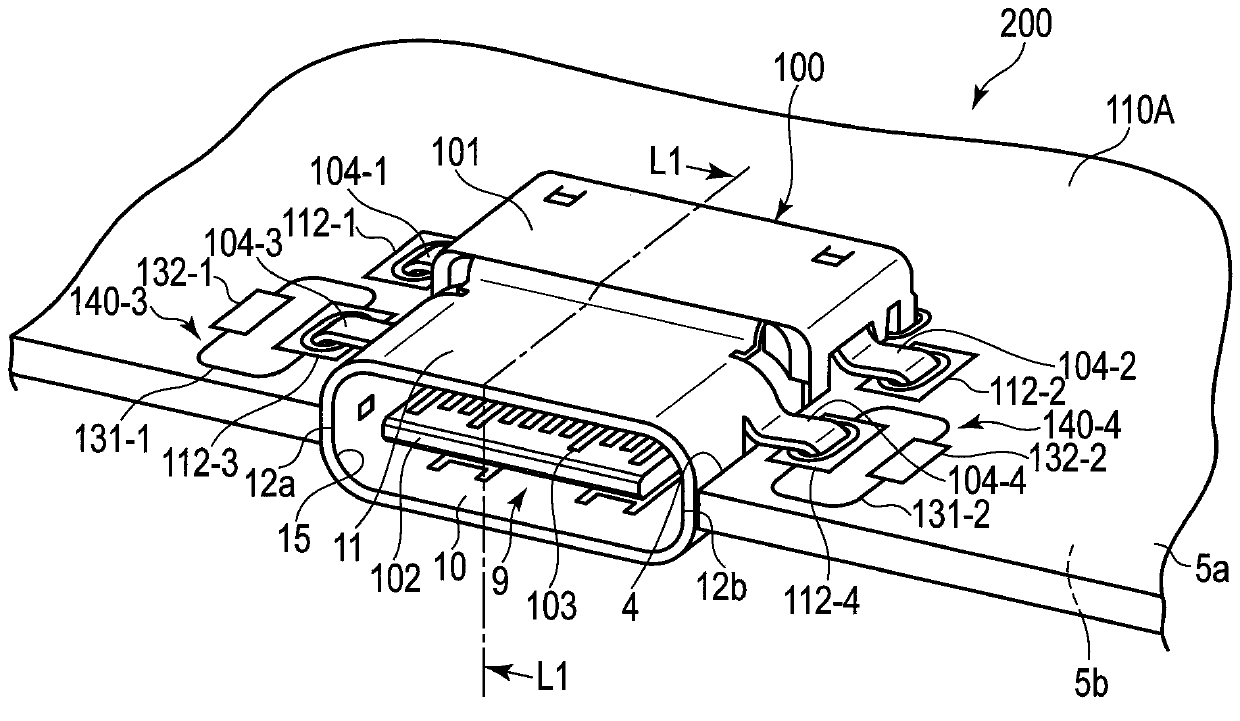

Printed wiring board

ActiveCN110809365AReduce adverse conditionsElectrically conductive connectionsPrinted circuit detailsMechanical engineeringElectrical and Electronics engineering

According to one embodiment, a printed wiring board includes a wiring board, a connector part, a connection pad provided between the wiring board and the connector part and connected with the connector part with a solder material, and a guide groove provided in the wiring board to be continuous to the connection pad, to guide a portion of the solder material from the connection pad.

Owner:KK TOSHIBA

Liquid crystal display panel with microlens array and method for manufacturing the same

InactiveCN101641634BPrevent intrusionShock suppressionNon-linear opticsLensLiquid-crystal displayMicro lens array

A highly reliable liquid crystal display panel in which such a trouble as mixture of foreign material is prevented. The reliable liquid crystal display panel comprises a bonded substrate including a pair of substrates and a liquid crystal layer arranged therebetween, a microlens array provided on the light incident side of the bonded substrate, a support provided on the light incident side of thebonded substrate to surround the microlens array, and an optical film attached to the bonded substrate through the support. The support has a portion projecting farther to the outer space side than the major surface of the outer surface of the support, and a vent connecting the inner space surrounded by the support and the outer space. The opening of the vent on the outer space side is formed in the projection.

Owner:SHARP KK

Glue spreading apparatus, using and maintaining method for the glue spreading apparatus

InactiveCN101318169BHigh strengthNo bending deformationLiquid surface applicatorsSpraying apparatusConical tubeEngineering

The invention discloses a rubberizing device, comprising a base, a pin base, a rubberizing pin on the pin base, a fixing mechanism and a pin protecting mechanism. In an embodiment of the invention, the fixing mechanism comprises a slide block and a clamp; wherein the slide block can be arranged on a guide rail of the base in a sliding way, and drives the pin base and the rubberizing pin to lift up and down to adjust the distance between the fixing mechanism and the pin protecting mechanism; the clamp is connected with the slide block to clamp the pin base. The pin protecting mechanism comprises a conical tube; the conical tube can be separately sheathed on the outside of the rubberizing pin. During the use and maintenance of the rubberizing device, when the distance between the fixing mechanism and the pin protecting mechanism is increased, the rubberizing pin can be moved out of the pin protecting mechanism thus realizing quick replacement and improving the operation efficiency.

Owner:AU OPTRONICS (XIAMEN) CORP +1

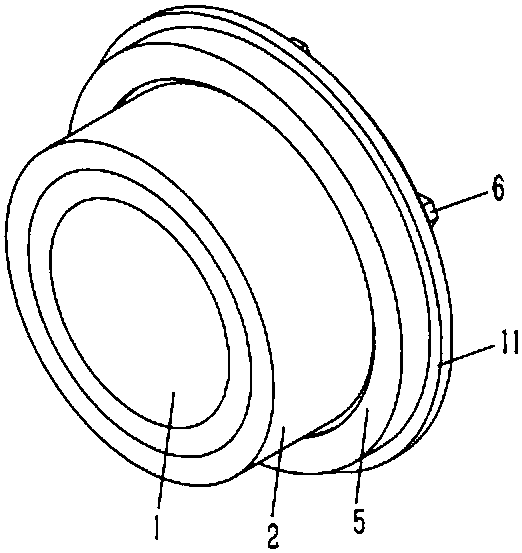

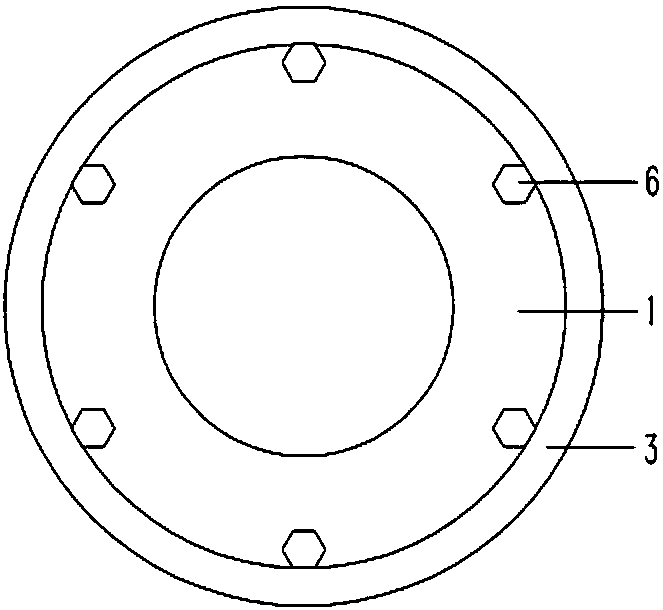

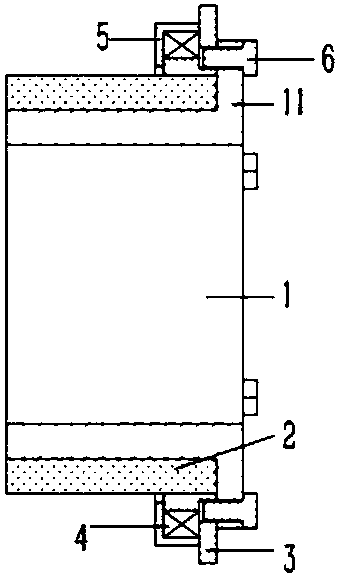

Polyurethane foot wheel

The invention discloses a polyurethane foot wheel. The polyurethane foot wheel comprises a base wheel body, the outer wall of the base wheel body is poured with a polyurethane outer wheel body, a flange is formed on one side of the base wheel body, the polyurethane outer wheel body is sleeved with an outer fixing sleeve in an inserted mode, a stop ring is formed on one side of the outer fixing sleeve, the stop ring of the outer fixing sleeve abuts against the flange of the base wheel body, bolts penetrate through the flange of the base wheel body to be in threaded connection with the stop ringof the outer fixing sleeve, a bearing is fixed to the outer fixing sleeve in an inserted sleeved mode, an anti-wear sleeve is fixed to the outer ring of the bearing in an inserted sleeved mode, and an anti-wear ring is formed on the front side of the anti-wear sleeve. The anti-wear sleeve in contact with a guide rail and capable of rotating relatively is arranged on the polyurethane foot wheel, friction between the polyurethane foot wheel and the guide rail can be reduced, defective conditions of operation of a trolley on the guide rail are reduced, and the guide rail is protected.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

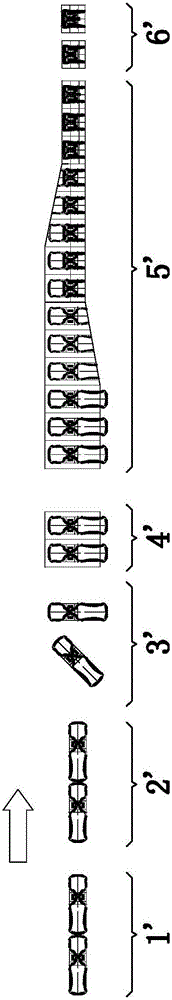

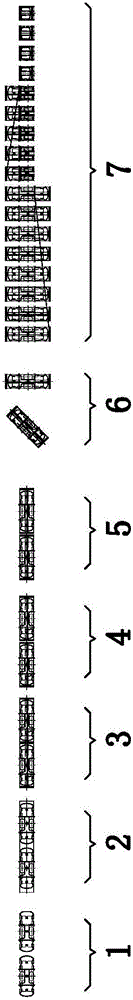

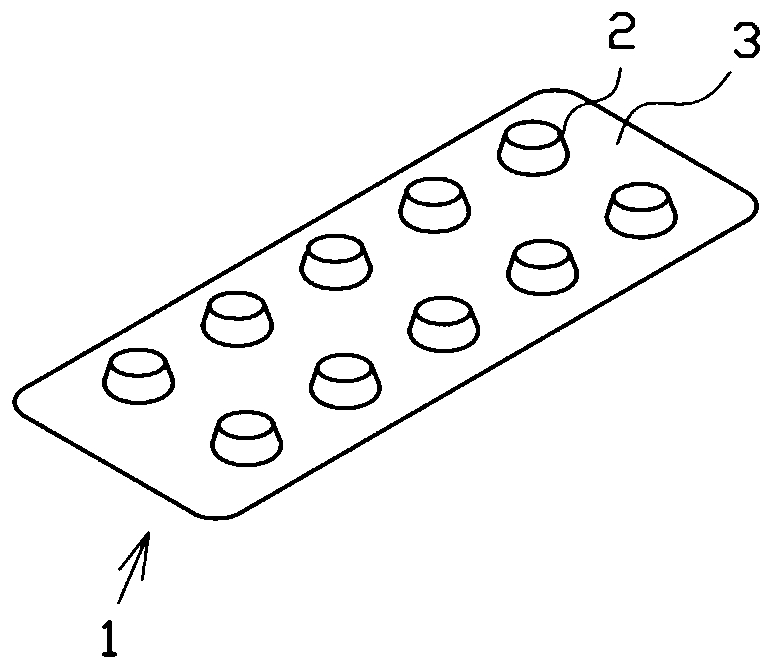

Tablet filling device, PTP packaging machine, and method for manufacturing a PTP shee

ActiveCN110615132AReduce adverse conditionsPrint fitWrappingPackaging automatic controlEngineeringPackaging machine

The present invention addresses the problem of providing a tablet filling device, a PTP packaging machine, and a method for manufacturing a PTP sheet, with which it is possible to suppress a decreasein the appearance quality of a tablet printed on both surfaces. The tablet filling device (21) is provided with: a first rotating cylinder (47) that sucks and holds tablets (5) supplied from a supply / dispensing unit (46) and transports the tablets; a first printing mechanism (50) that prints on one surface of the tablet (5) conveyed by the first rotating cylinder (47); a second rotating cylinder (48) capable of transferring the tablets (5) that have been printed on one surface thereof by the rotating cylinder (47), holding the tablets (5) by suction, and conveying the tablets (5); a second printing mechanism (51) that prints on the other surface of the tablet (5) conveyed by the second rotating cylinder (48); and a third rotating cylinder (49) that inverts the tablet (5), which has been transferred by the second rotating cylinder (48) and printed on both surfaces, so as to fill the bag section (2) of the container film (3) with the inverted tablet (5) in such a manner that the other surface printed by the second printing mechanism (51) is positioned on the upper side.

Owner:CKD

Electric dust collector

InactiveCN100344250CEasy to operateImprove management abilitySuction hosesSuction handlesEngineeringVacuum cleaner

Owner:SANYO ELECTRIC CO LTD

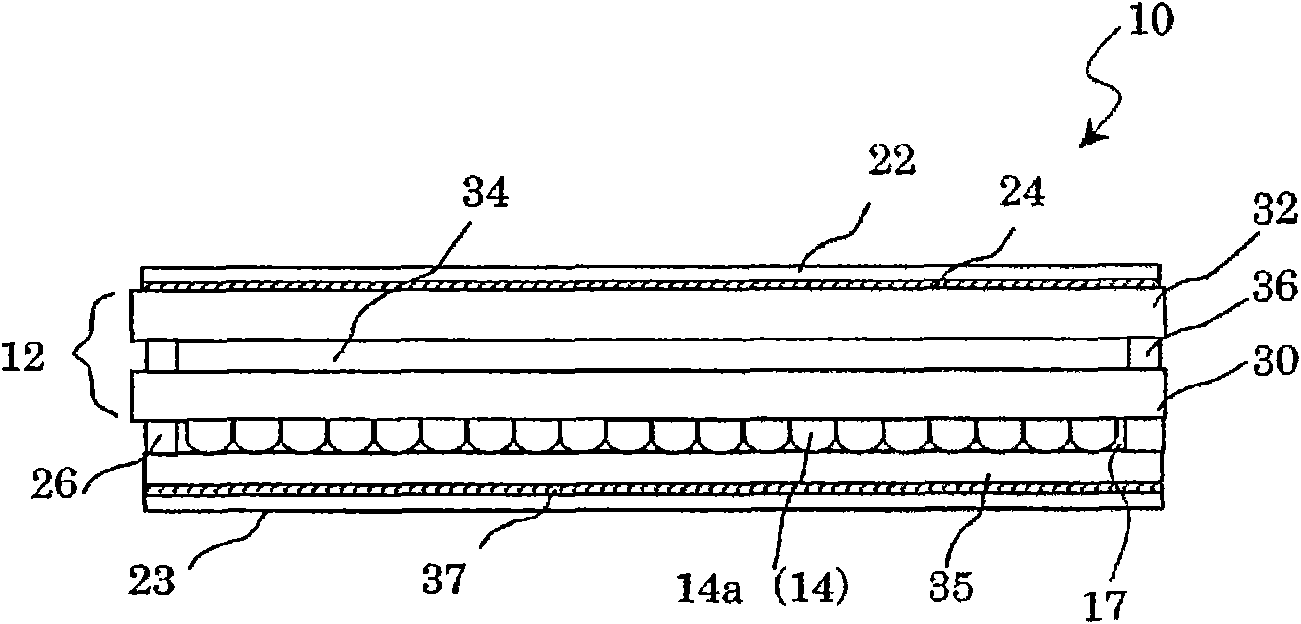

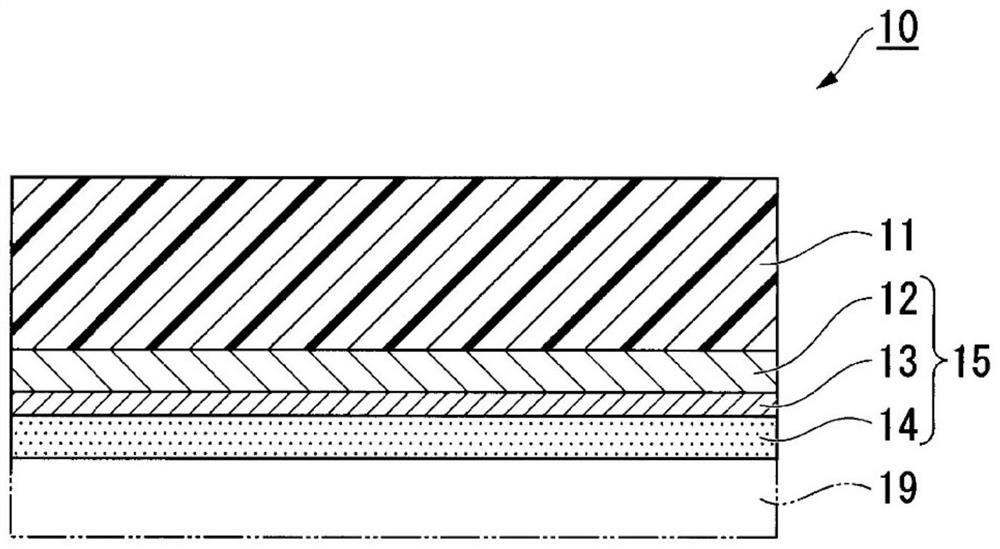

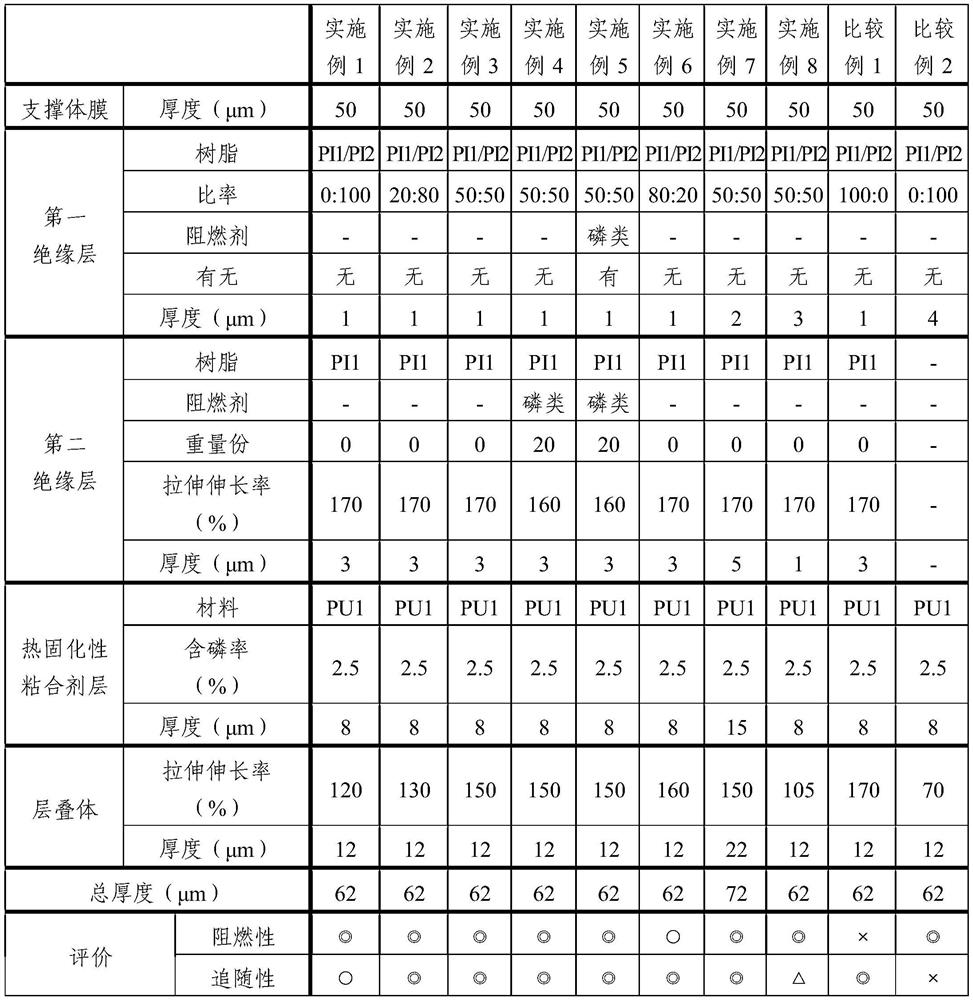

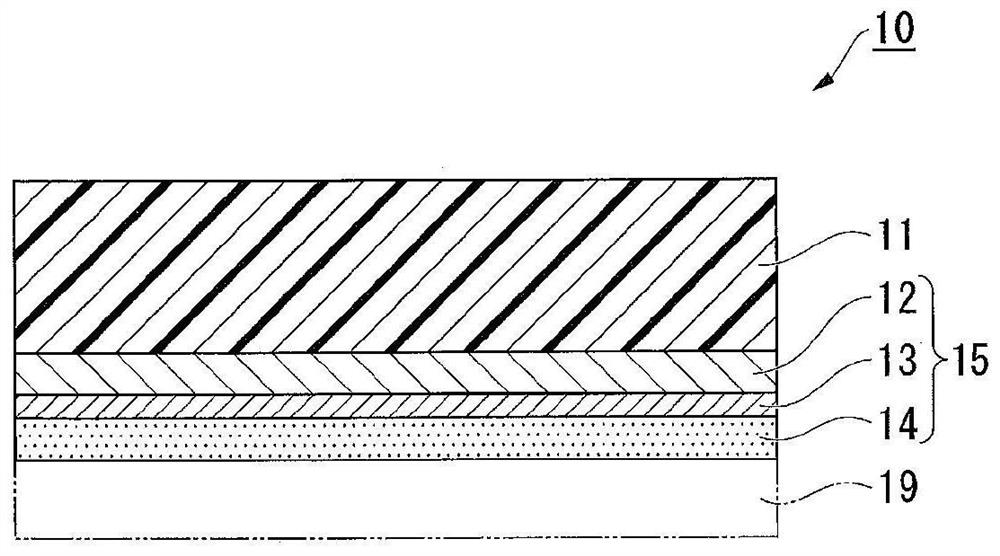

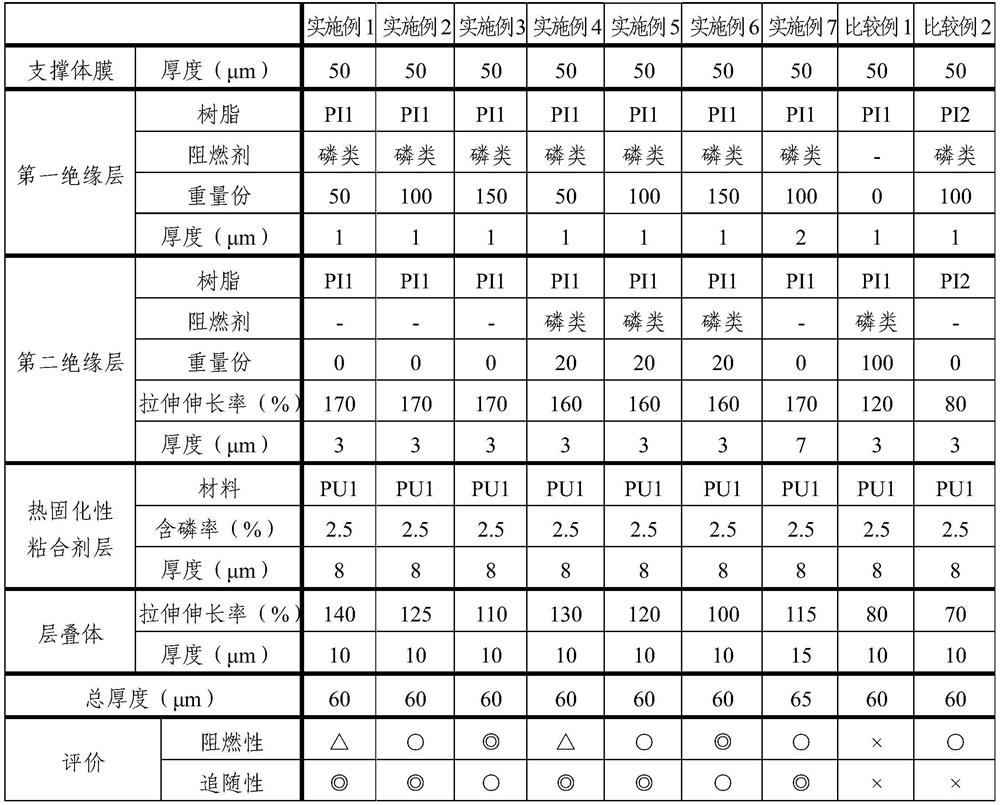

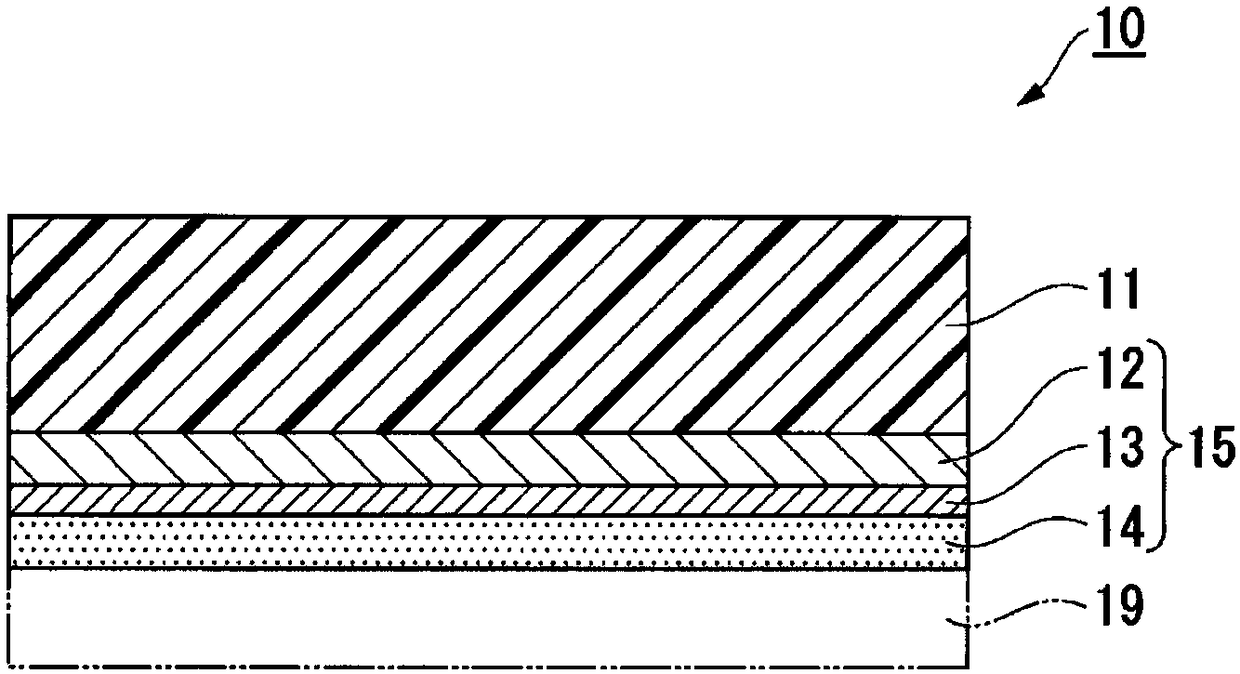

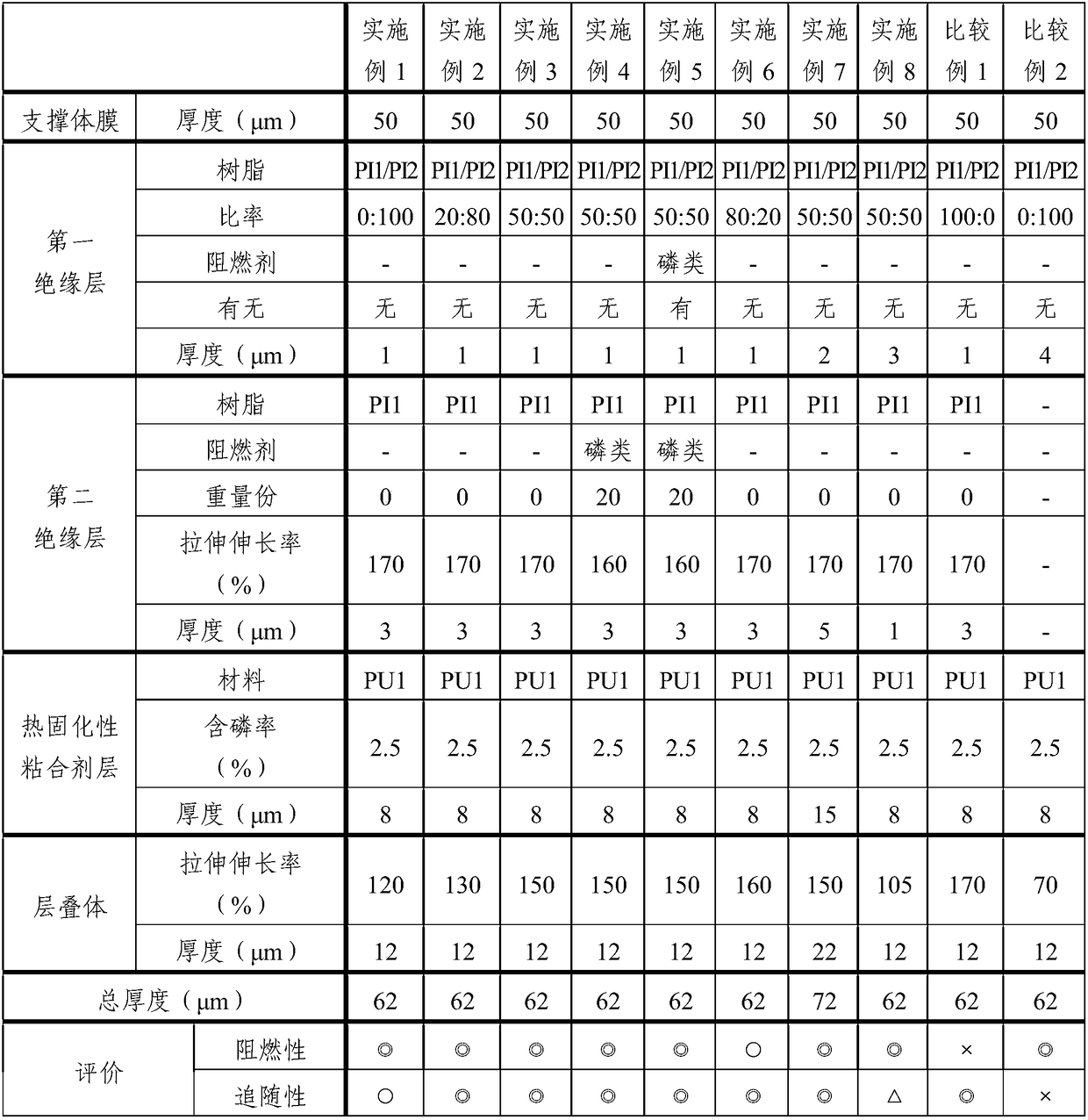

cover film

ActiveCN108624244BNo bad situationImprove protectionFilm/foil adhesive primer layersPolyureas/polyurethane adhesivesPolymer scienceThin membrane

The present invention provides a cover film that has good processability and handleability and is excellent in followability to FPC even if it is a thin film. The cover film (10) is characterized in that a first insulating layer (12), a second insulating layer (13), and a thermosetting adhesive layer (14) are sequentially laminated on one surface of a support film (11). The first insulating layer (12) contains a flame-retardant resin, and the support film (11) is removed from the first insulating layer (12), the second insulating layer (13), the thermosetting adhesive layer (14 ) The tensile elongation of the formed laminate (15) is 100% or more.

Owner:FUJIMORI KOGYO CO LTD

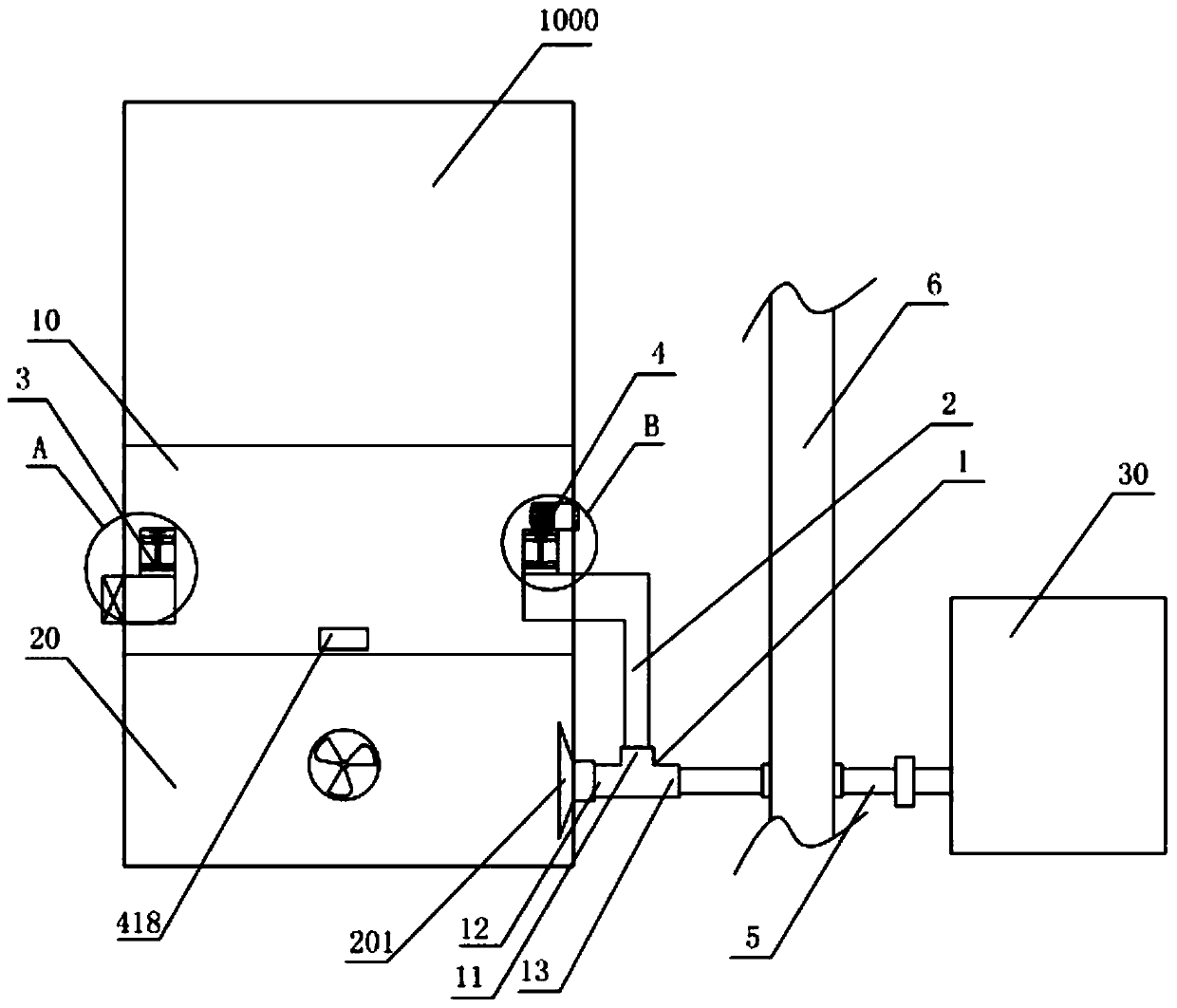

Tablet press and feeding detection device and ventilation device thereof

The invention belongs to the technical field of tablet presses, in particular to a tablet press and a feeding detection device and ventilation device thereof. A ventilation opening is formed in the tablet press, an airflow driving function of a dust remover is utilized, airflow in a driving cabin and airflow in a lower cabin of the tablet press are driven to flow, good heat dissipation and ventilation in the tablet press are achieved, heat accumulation in the tablet press is reduced, and the probability that parts of the tablet press are damaged or defective products are produced due to the high temperature is reduced; and a temperature switch, a lower cabin air outlet door linked with the temperature switch, and a lower cabin air inlet door which can be opened and closed as required arearranged, so that the lower cabin can be internally ventilated and cooled only when the temperature is too high, and the lower cabin air inlet door and the lower cabin air outlet door are closed whenthe temperature is not too high, so that the internal environment of the lower cabin is kept clean to the greatest extent. According to the feeding detection device, a proximity switch is arranged ina discharging pipeline, and an alarm is linked to identify and raise alarm against an insufficient state of the materials, so that the yield is improved.

Owner:SHANGHAI PHARMA GRP QINGDAO GROWFUL PHARMA CO LTD

cover film

ActiveCN107896417BNo bad situationImprove protectionCircuit bendability/stretchabilityFilm/foil adhesivesPolymer scienceThin membrane

The present invention provides a cover film that has good processability and handleability and is excellent in followability to FPC even if it is a thin film. The cover film (10) provided by the present invention is characterized in that the cover film (10) is formed by sequentially laminating a first insulating layer (12), a second insulating layer (13) on one surface of a support film (11), thermosetting Formed from a permanent adhesive layer (14), the first insulating layer (12) contains a flame retardant, and the support film (11) is removed, the first insulating layer (12), the second insulating layer (13 ), a laminate (15) composed of a thermosetting adhesive layer (14) has a tensile elongation of 100% or more.

Owner:FUJIMORI KOGYO CO LTD

Buckling process for disposable absorbent article fixed patches

ActiveCN103350802BImprove stabilityEfficiently adjust the distancePackagingRelative displacementEngineering

The invention relates to the producing and manufacturing field of disposable absorbent articles, in particular to a buckling process for disposable absorbent article fixed patches. The buckling process is simple in operation mode, and capable of effectively enabling the fixed patches to be buckled tightly and enabling the fixed patches not to be separated easily in production. The buckling process includes the first step of tucking up the fixed patches of the produced disposable absorbent articles, then pressing down the fixed patches by means of a pressing plate, and enabling buckling bodies of two pairs of opposite fixed patches to be buckled with plush faces, the second step of inputting the disposable absorbent articles to a twisting device, conveying the disposable absorbent articles through the twisting device, enabling the upper surfaces and the lower surfaces of each pair of fixed patches of the disposable absorbent articles to carry out relative displacement movement by means of the twisting motion of the twisting device, namely, each buckling body generates the relative displacement movement with the plush faces, wherein the time of the relative displacement movement is 0.05-0.5 second, and then continuing to convey the disposable absorbent articles, and the third step of outputting the disposable absorbent articles from the twisting device and inputting the disposable absorbent articles to a folding process.

Owner:QUANZHOU HANWEI MACHINERY MFG

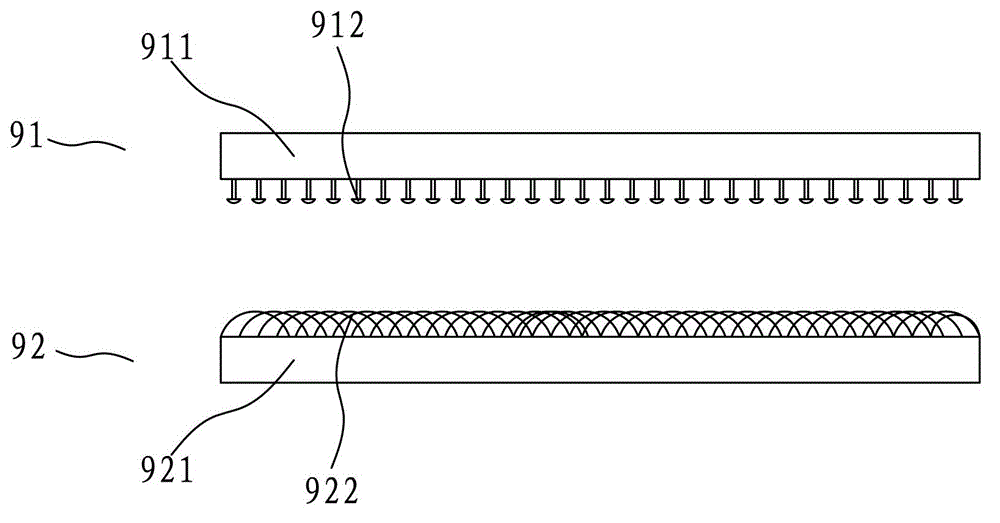

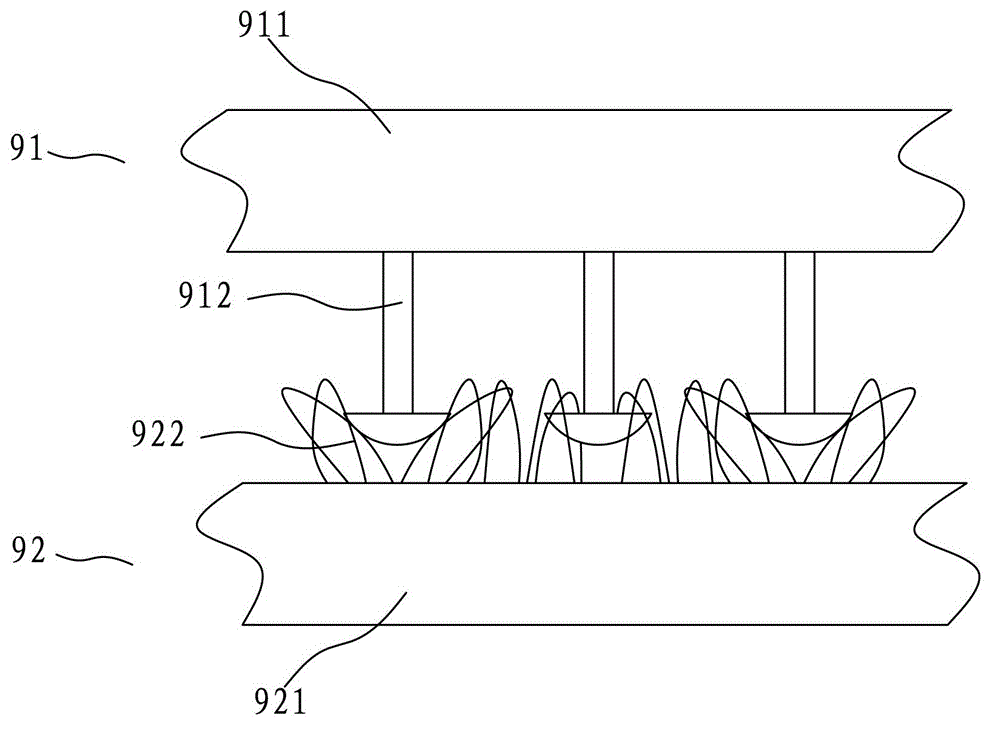

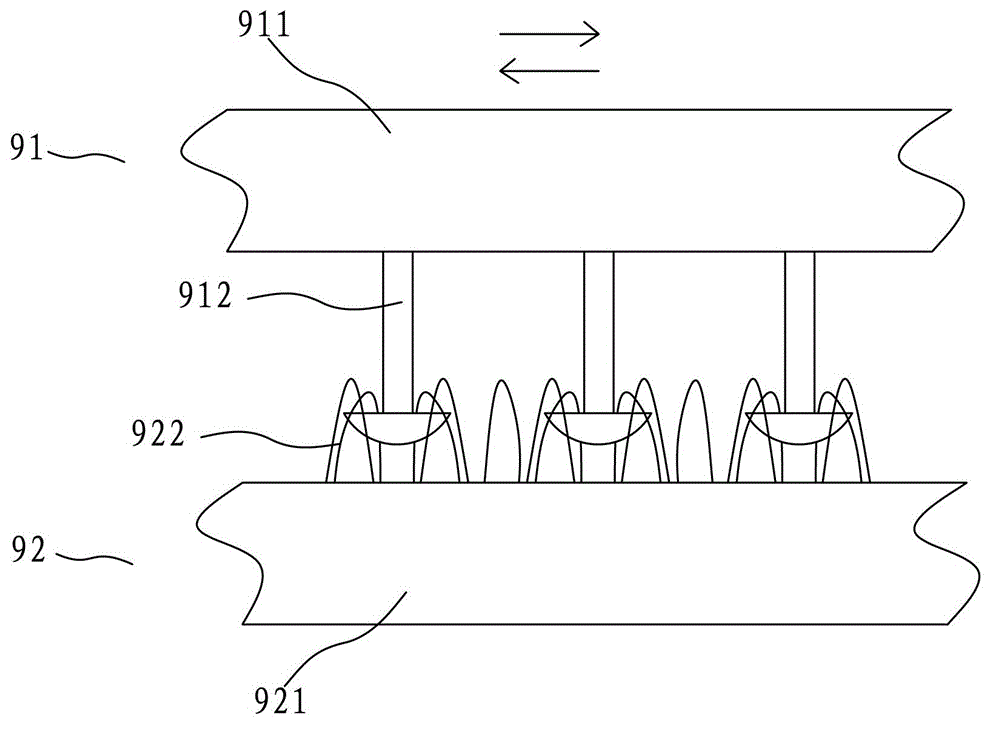

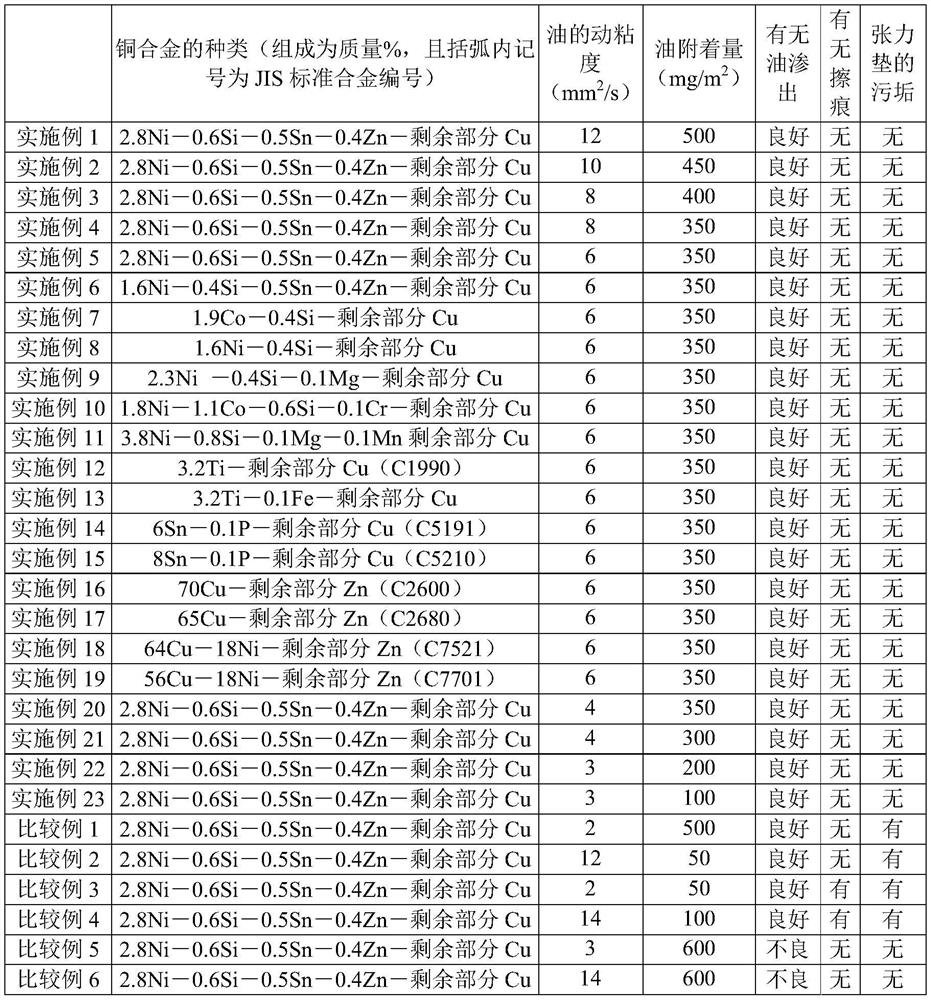

Copper or copper alloy lath and reciprocating coil and method of making the same

ActiveCN110770367BInhibitionReduce adverse conditionsMetallic material coating processesMetal rolling arrangementsMetal powderCopper alloy

The present invention provides a reciprocating coil of copper or copper alloy lath that is unlikely to generate metal powder due to friction with a tension pad, and a manufacturing method thereof. The present invention is a copper or copper alloy strip, the surface of which is coated with a kinematic viscosity of 3-12 mm 2 / s of oil, and the amount of the above oil is 100-500 mg / m 2 .

Owner:JX NIPPON MINING & METALS CORP

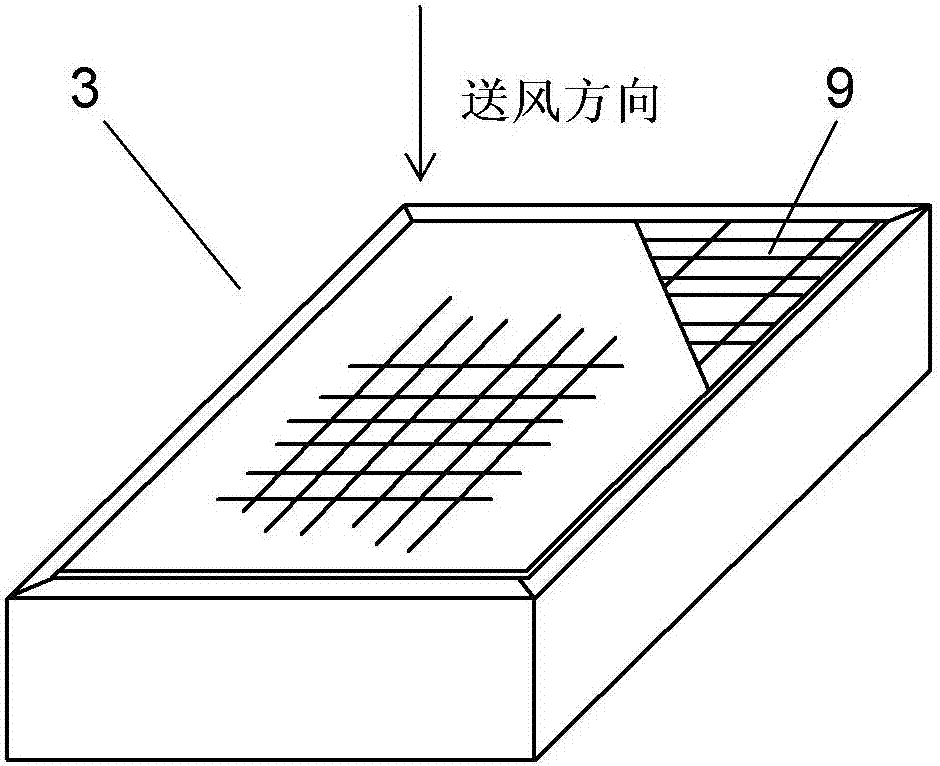

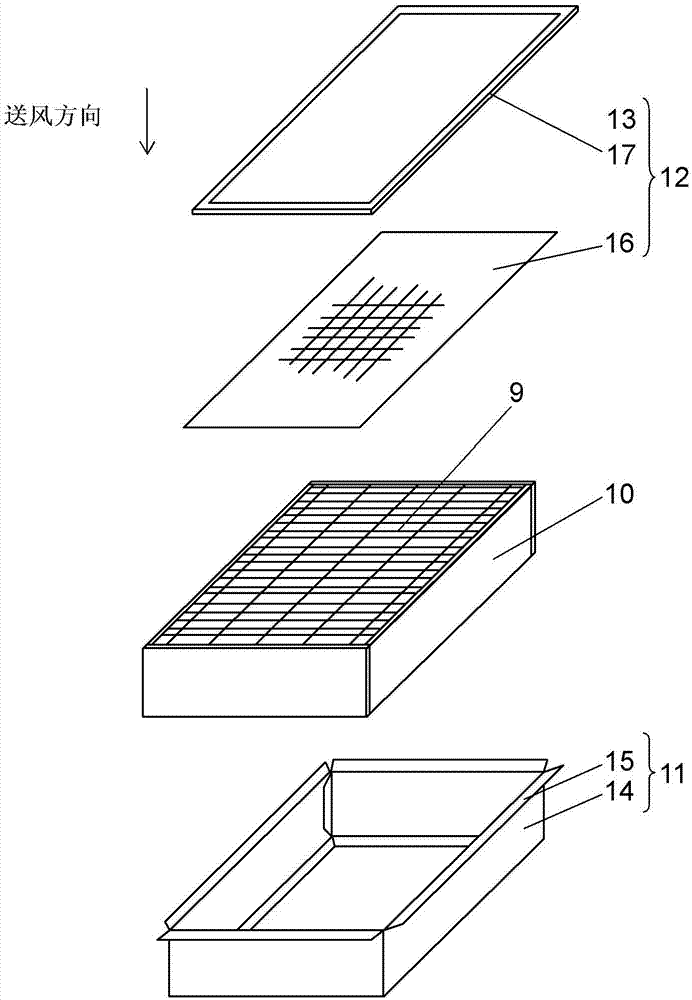

Air filter and air cleaning device using the same

InactiveCN105435548AReduce adverse conditionsDispersed particle filtrationFiltration separationFistAir filter

The air cleaning device comprises a first filter (9) in a folding shape, a first frame (10) keeping the shape of the fist filter (9), a second frame (11) fixed at the first frame (10), and a second filter (12) arranged at the surface of one side of the first filter (9). The second filter (12) includes a wrinkling restriction part (13) configured to restrict the wrinkling of the second filter (12), and installed at the second frame (11) to further reduce the poor technology of the air filter. The second filter is able to be taken as different parts of the wrinkling restriction part (13) for restricting the wrinkling of the second filter (12) to manufacture, so that the structure of an air filter is stable and is not easy to have good conditions at work.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

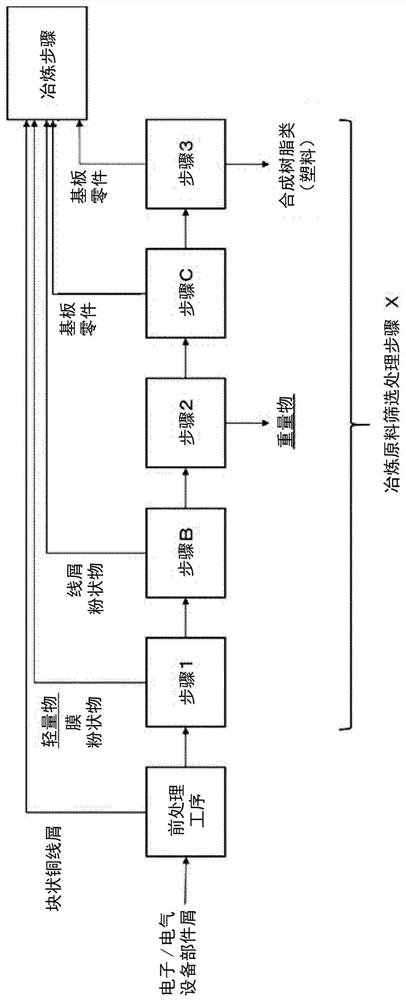

Processing method and processing device for electronic/electrical device component scrap

PendingCN113710383AReduce adverse conditionsProgramme-controlled manipulatorImage enhancementSmelting processCopper wire

Owner:JX NIPPON MINING & METALS CORP

Stator heating method

InactiveCN112531994AReduce adverse conditionsShorten heating timeManufacturing dynamo-electric machinesChemistryProcess engineering

The invention discloses a stator heating method. The method comprises the following steps of firstly, roughening the surface of a stator, then cleaning and drying the stator, removing moisture attached to the end part of a stator coil, preheating the stator for later use, adding a resin material into a plastic extruding machine, and extruding molten resin through the plastic extruding machine, adding a proper amount of diluent into the resin in the molten state. The method is advantaged in that the heating time of the stator can be shortened, the stator can be efficiently and uniformly preheated to a fixed temperature range, the heating efficiency of the stator is improved, the production quality and the production efficiency of the stator can be further improved, and the problems that thestator is not preheated at present, resin needs to be cured for a long time and production cost is high are solved; fluidity of the resin is obviously worsened during molding, and the defects of unfilling and the like are possibly caused, so the production quality of the stator is reduced, and the service life of the stator can be prolonged.

Owner:南京金志精密机电有限公司

Coverlay film

ActiveCN108624244ANo bad situationImprove protectionFilm/foil adhesive primer layersPolyureas/polyurethane adhesivesOperabilityMaterials science

The present invention provides a coverlay film which is excellent in processing suitability, operability and adherence to FPC even if the coverylay film is a thin film. The coverlay film is characterized in that, a first insulating layer (12), a second insulating layer (13) and a thermosetting adhesive layer (14) are sequentially laminated on one surface of a support film (11),, wherein the firstinsulating layer (12) contains a flame retardant resin. The tensile elongation of a laminate (15) formed by the first insulating layer (12), the second insulating layer (13) and the thermosetting adhesive layer (14) without the support film (11) is over 100%.

Owner:FUJIMORI KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com