Copper or copper alloy lath and reciprocating coil and method of making the same

A manufacturing method and technology of copper alloy, applied in the direction of metal rolling, metal material coating process, coating, etc., can solve problems such as scars, and achieve the effect of inhibiting the generation of metal powder and reducing bad conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

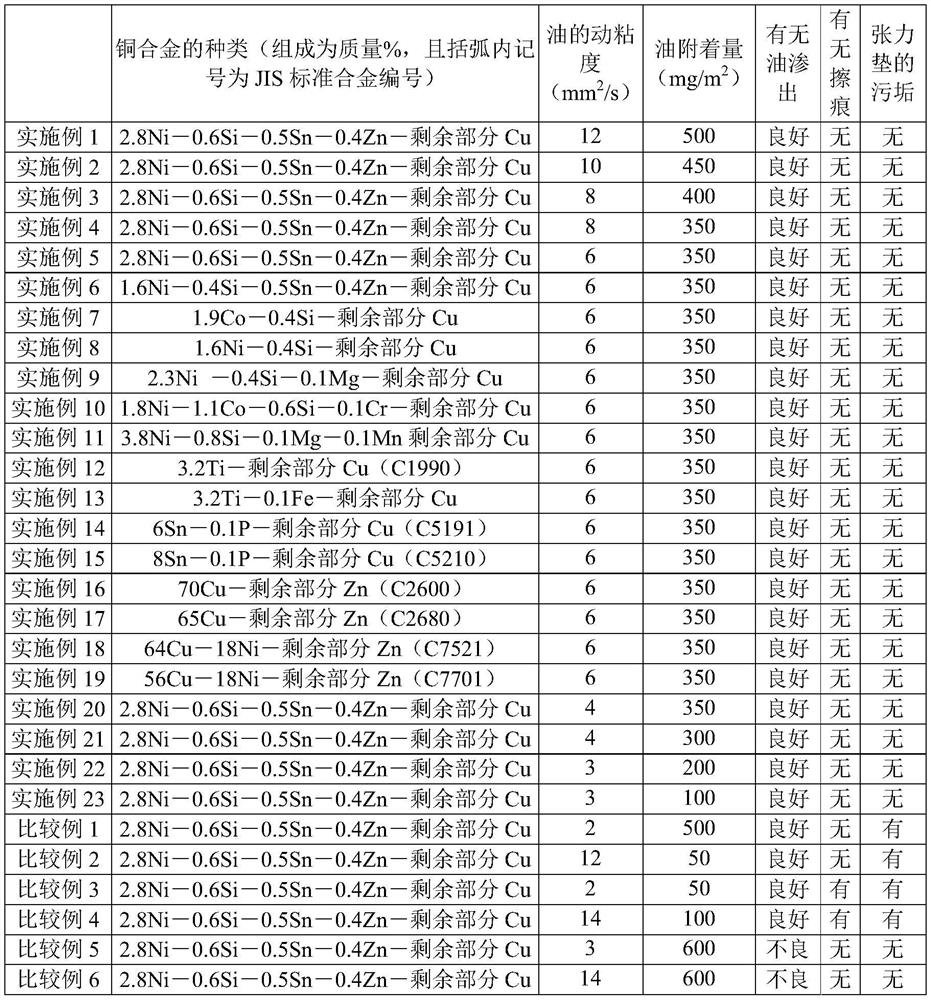

[0040] Examples of the present invention are shown below, but the examples are provided for better understanding of the present invention and its advantages, and are not intended to limit the invention.

[0041] (Example, Comparative Example)

[0042] A reflow tinned copper alloy strip with a width of 20 mm and a thickness of 0.2 mm was coated with lubricating oil (hydrocarbon-based) of the kinematic viscosity and amount shown in Table 1, wound into a reciprocating coil, wrapped with rust-proof paper, and used on rails. It is transported over a distance of 300 km, and then returns to the factory where the reciprocating coil is produced by the same route. After a period of 7 days from the date of return, check whether oil seeps out from the reciprocating coil in the workshop, rewind the reciprocating coil, check whether the reflowed tin-plated copper alloy strip has scratches, and check whether the reflowed tin-plated copper alloy strip has scratches, and is used and tensioned....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com