Coverlay film

A covering film and body film technology, applied in the direction of film/sheet release coating, film/sheet adhesive, application, etc., can solve the problems of poor processing suitability, poor operability, lack of flexibility, etc., and achieve bending Excellent properties, reduced defects, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] A polyethylene terephthalate (PET) film having a thickness of 50 μm that was subjected to a release treatment on one surface was used as the support film 11 .

[0093] A solvent-soluble polyimide that does not contain a phosphorus-based flame retardant and is made of a flame-retardant polyimide resin (polyimide resin that does not contain aliphatic units) so that the thickness after drying becomes 1 μm. The resin coating solution was cast-coated on one surface of the support film 11 and dried to form the first insulating layer 12 .

[0094] Highly extensible polyimide resin (containing (CH 2 CH 2 CH 2 CH 2 -O-) 10 Coating solution of a solvent-soluble polyimide resin that does not contain a flame retardant and has a tensile elongation after drying of 170% formed as an aliphatic unit polyimide resin), cast coating On the first insulating layer 12, it was dried, and the second insulating layer 13 was formed.

[0095] 2.4 parts by weight of polyfunctional epoxy resin...

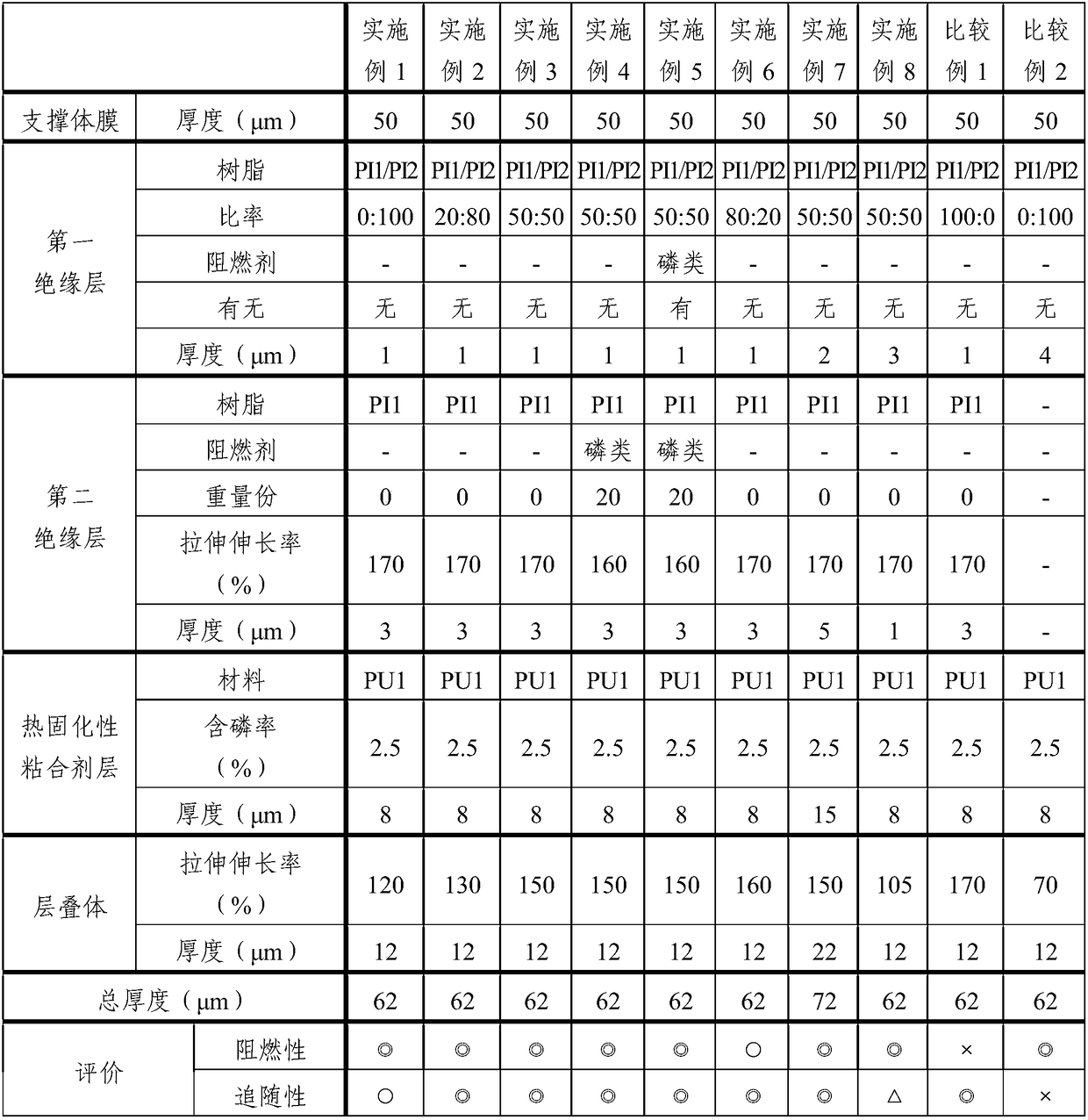

Embodiment 2、3

[0097] Except that the polyimide resin contained in the first insulating layer 12 is set to use the above-mentioned highly extensible polyimide resin and the above-mentioned flame-retardant polyimide resin at the same time, and in Example 2, the resin In Example 3, the weight ratio of the resin was 20:80 and the weight ratio of the resin was 50:50, and the cover films of Examples 2 and 3 were obtained in the same manner as in Example 1.

Embodiment 4

[0099] Except that the coating solution for forming the second insulating layer 13 is a coating solution of a solvent-soluble polyimide resin containing 20 parts by weight of a phosphorus-based flame retardant with respect to 100 parts by weight of the resin, in the same manner as in the implementation In the same manner as Example 3, the covering film of Example 4 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com