Dual tube and connecting structure thereof

A technology of connecting structure and double pipe, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of inner pipe damage, troublesome stamping waste removal, and inability to remove stamping waste by crimping and fixing, so as to avoid conflicts. Effect

Active Publication Date: 2015-07-22

WATANABE SEISAKUSHO KK

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

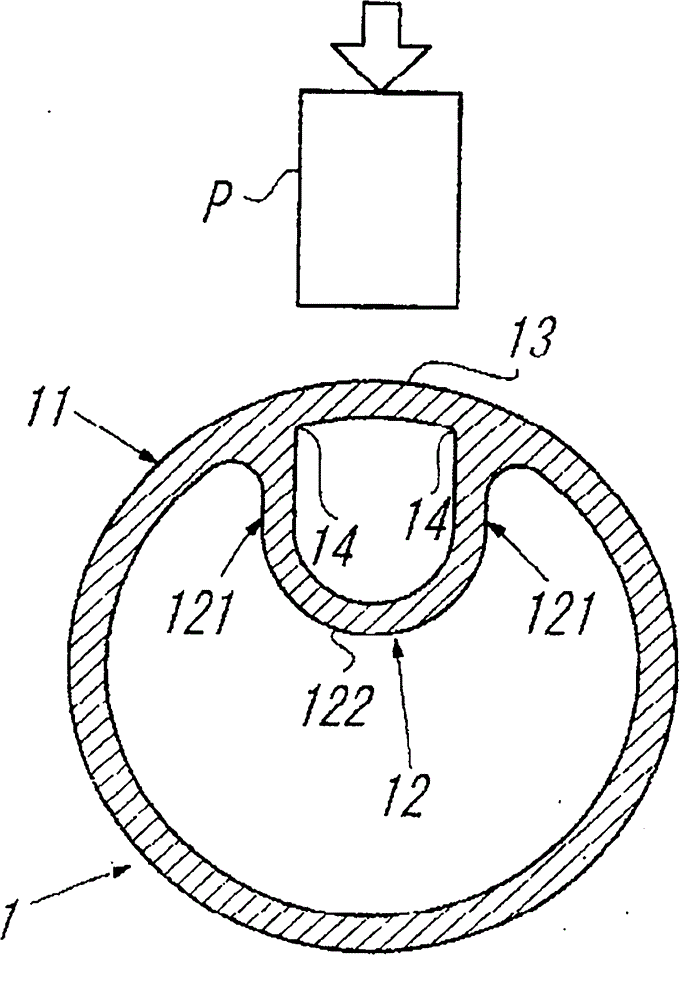

[0010] In the double pipe of Patent Document 1, in order to carry out the branch connection of the inner pipe, when the common part of the outer pipe and the inner pipe is pierced by a punching method that does not generate chips, there is the following problem: when the inner pipe is small, Because the stamping waste conflicts with the inner tube, the inner tube is damaged by the stamping waste or the stamping waste is crimped and fixed on the inner tube and cannot be removed; in the case of a large inner tube, because the stamping waste is hidden in the inner corner of the inner tube, Therefore, the removal of stamping waste becomes troublesome

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

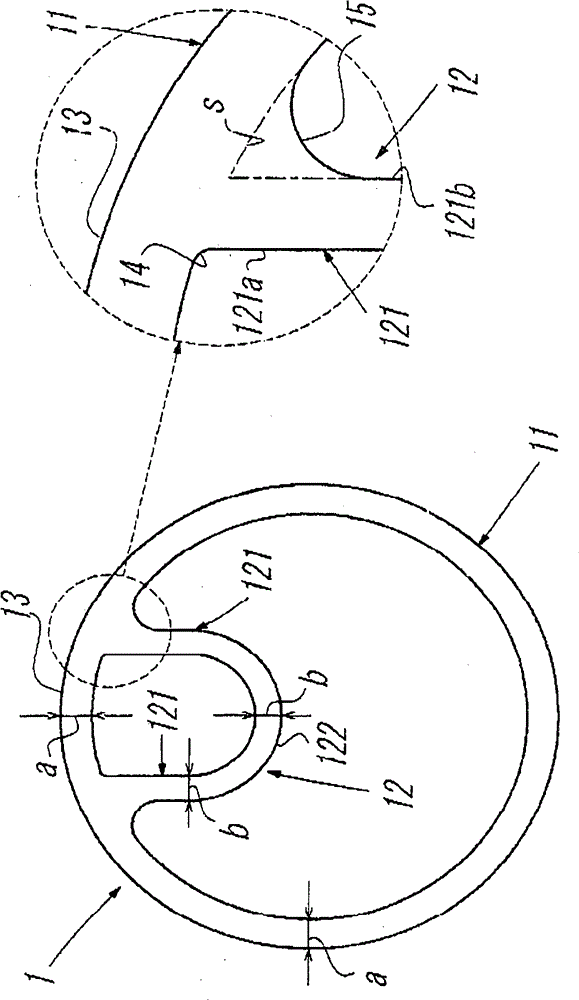

[0068] When the embodiment of the double pipe and its connecting structure for carrying out the present invention is used as a refrigerant passage of an in-vehicle air conditioner, the outer diameter of the outer pipe 11 of the double pipe 1 is 19 mm, and the wall thickness a is 1.2 mm The inner tube 12 of the double tube 1 has a wall thickness of 1.0 mm, and the inner surface 121a of the side wall 121 is spaced 5 mm apart.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

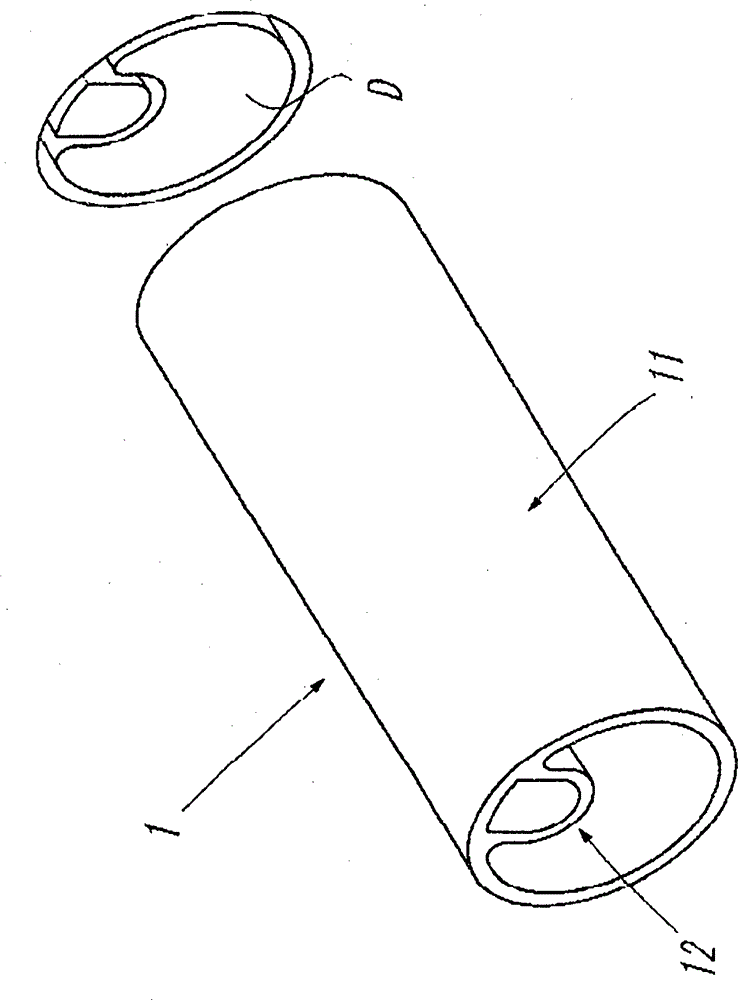

The invention provides a dual tube and a connecting structure thereof. When a common part of an outer tube and an inner tube undergoes stamping perforation processing for connecting the inner tube, defective conditions caused by stamping of waste materials are avoided. An inner tube (12) is arranged inside an outer tube (11); parts of the outer tube (11) and the inner tube (12) are unified into a whole; the inner tube (12) is provided with side walls (121) extending oppositely in parallel from a common part (13) of the outer tube (11) and the inner tube (12) with the diameter direction of the outer tube (11) between the side walls; and the depth end of the side wall (121) and opposite depth walls (122) of the common part (12) of the outer tube (11) and the inner tube (12) are not expanded to a degree exceeding the space between the side walls (121).

Description

technical field [0001] The invention belongs to the technical field of a double pipe in which an inner pipe is arranged inside an outer pipe, and fluids such as liquid and gas are respectively circulated in the outer pipe and the inner pipe, and a connection structure thereof. Background technique [0002] Recently, in order to make the flow path of the fluid compact, the double tube has been popularized in a wide range of industrial fields, and various improvements have been tried on the relative arrangement structure of the outer tube and the inner tube. [0003] Conventionally, as a double tube, the structure described in patent document 1 is known, for example. [0004] Patent Document 1 describes a double tube in which an outer tube and an inner tube are integrally formed by bending a metal plate. [0005] In the double tube of Patent Document 1, a part of the outer tube and the inner tube are shared, so that the amount of manufacturing material is reduced, and the man...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16L9/19F16L39/00

Inventor 佐藤进

Owner WATANABE SEISAKUSHO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com