Bidentate phosphorus ligand polymer, preparation method thereof and application in olefin hydroformylation reaction

An olefin hydroformyl and polymer technology is applied in the field of bidentate phosphorus ligand polymers, which can solve the problems of low catalytic performance and achieve the effects of high selectivity, low temperature and strong substrate universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

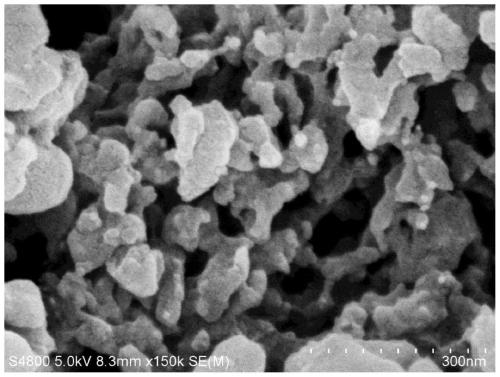

[0055] Preparation Example 1: Preparation of bidentate phosphorus ligand polymer represented by the following formula (I)

[0056]

[0057] In the formula (I), m:n=1:10, which means that the molar ratio of the bidentate phosphorus monomer and the styrene monomer constituting the bidentate phosphorus ligand polymer is 1:10; the structure of the formula (I) is not Indicates the linking order of each monomer, and the linking order of each monomer is not fixed, and it is a random polymer.

[0058] The bidentate phosphorus ligand polymer represented by formula (I) is prepared according to the following method:

[0059] Step 1: Add THF (100mL) and TEA (18mL, 3.5eq) to a 250ml three-neck flask under argon protection, and add PCl slowly at 0°C 3 (5g, 1eq), and stirred for 5 minutes after the addition, slowly added pyrrole (5g, 2eq, (Compound A)) dropwise at 0°C, and stirred at room temperature for 6h. After filtration, the filter cake was washed with THF, the filtrate was evapora...

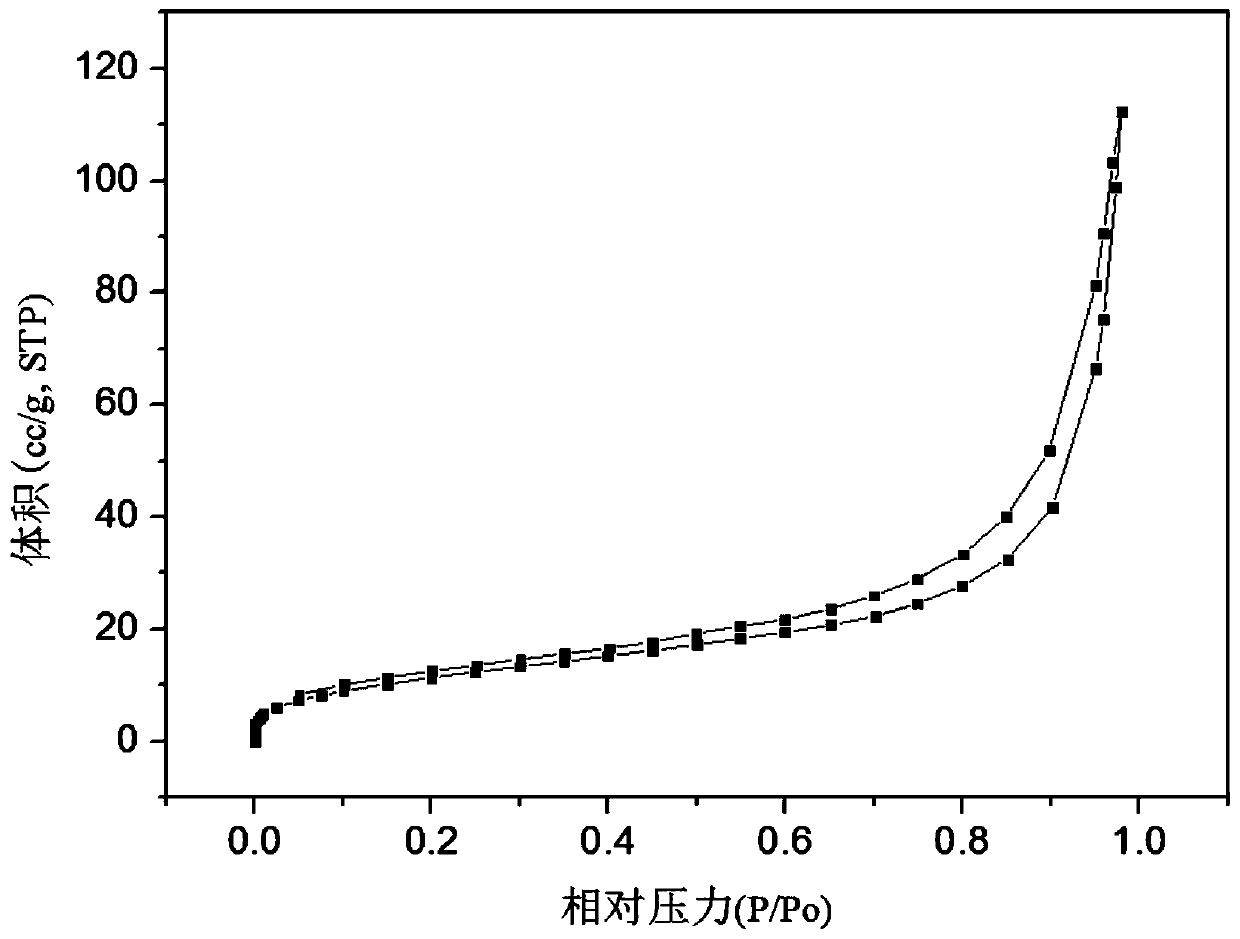

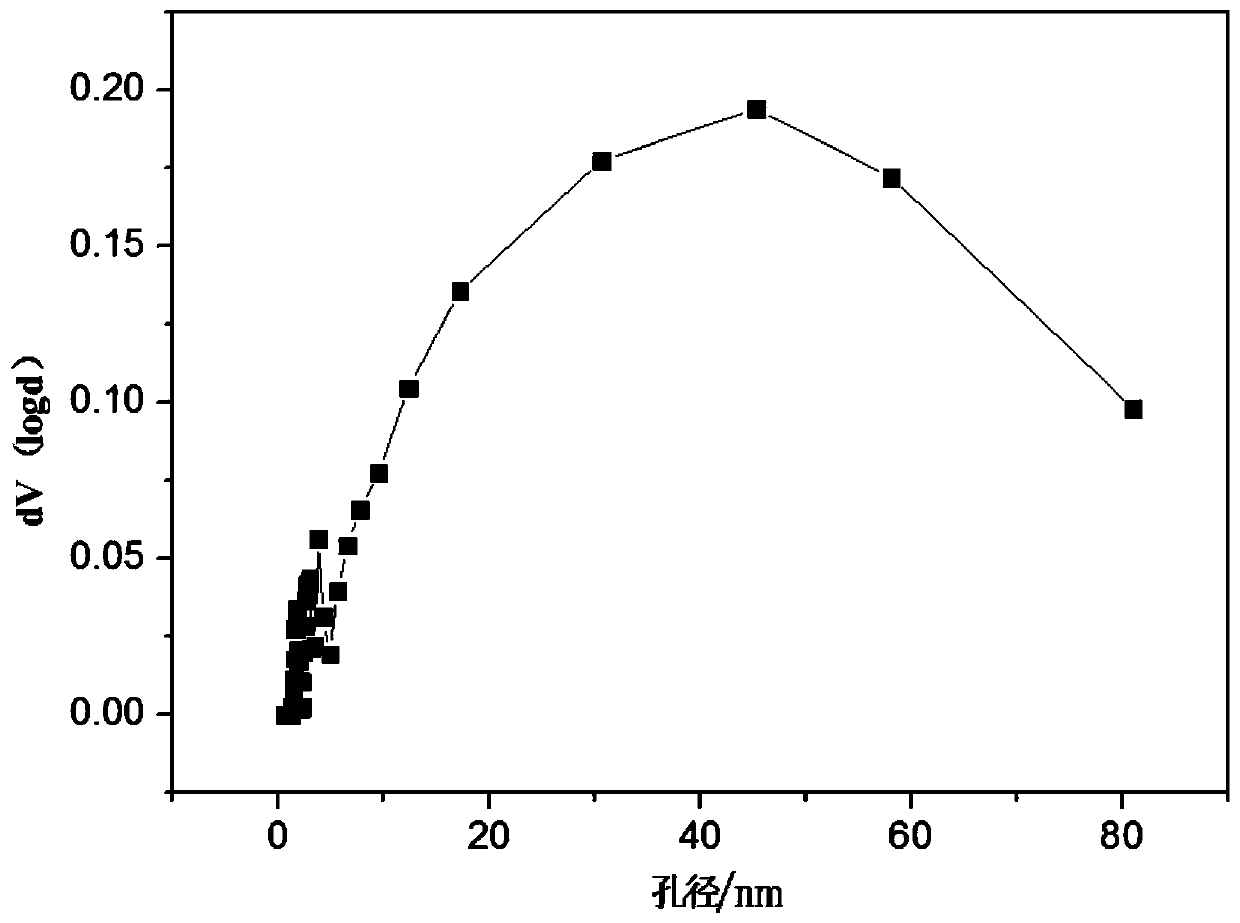

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com