Elastic inner expansion automatic clamp

An internal expansion and fixture technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of roundness deformation of inner holes, unguaranteed radial jumps of machined parts, severe problems, etc., to achieve sufficient clamping and ensure processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

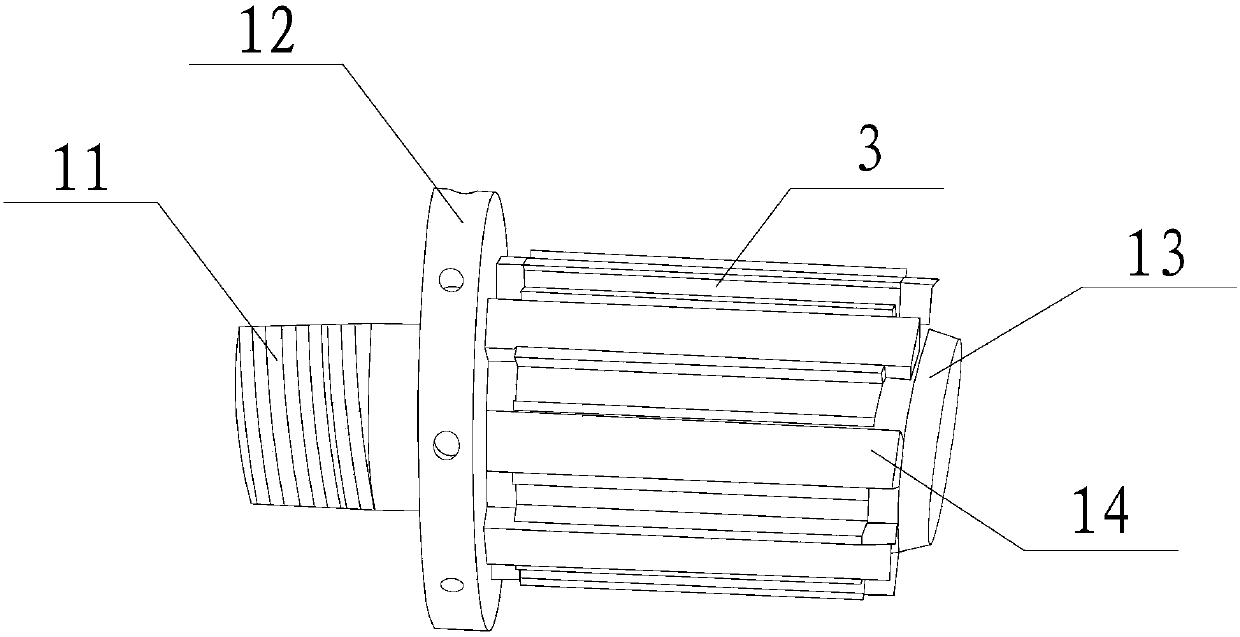

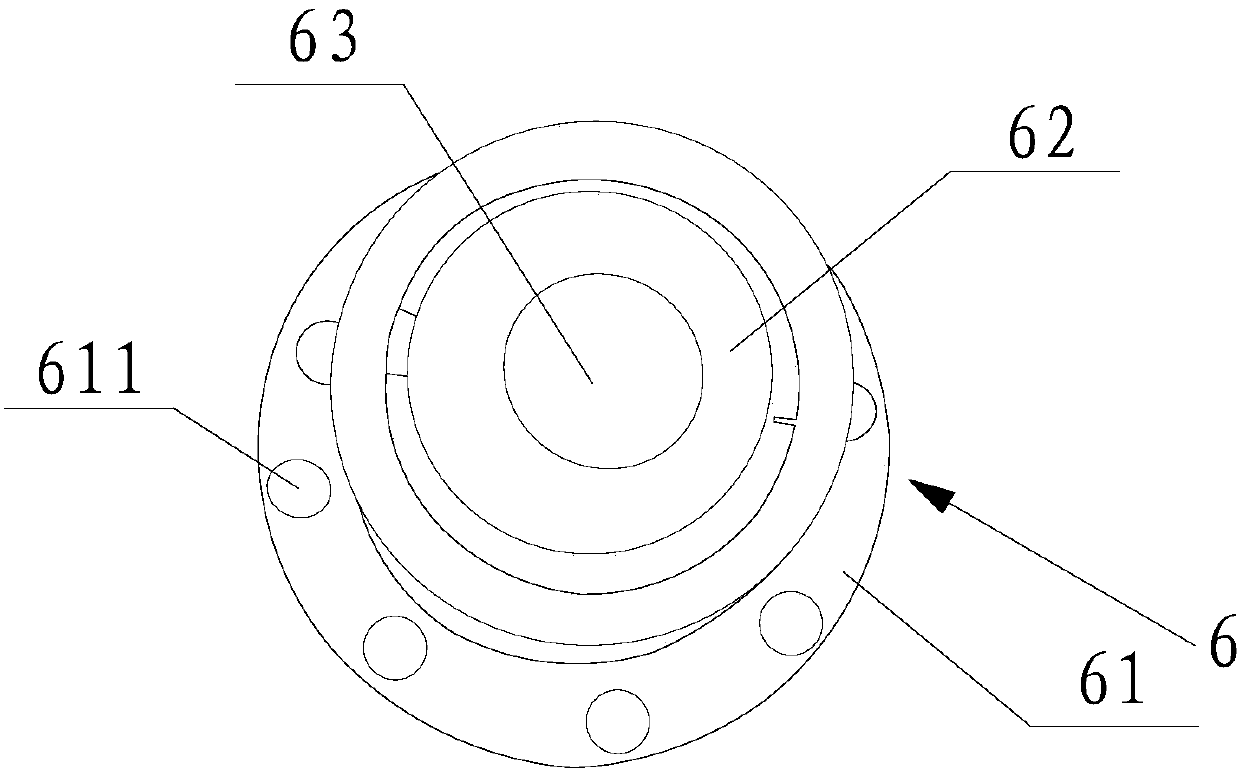

[0025] Such as Figure 1 to Figure 5 The shown elastic internal expansion automatic clamp mainly includes a clamp body 1, an elastic block 2, a support body 3, a spacer 4, a support plate 5 and a flange assembly 6 and other components.

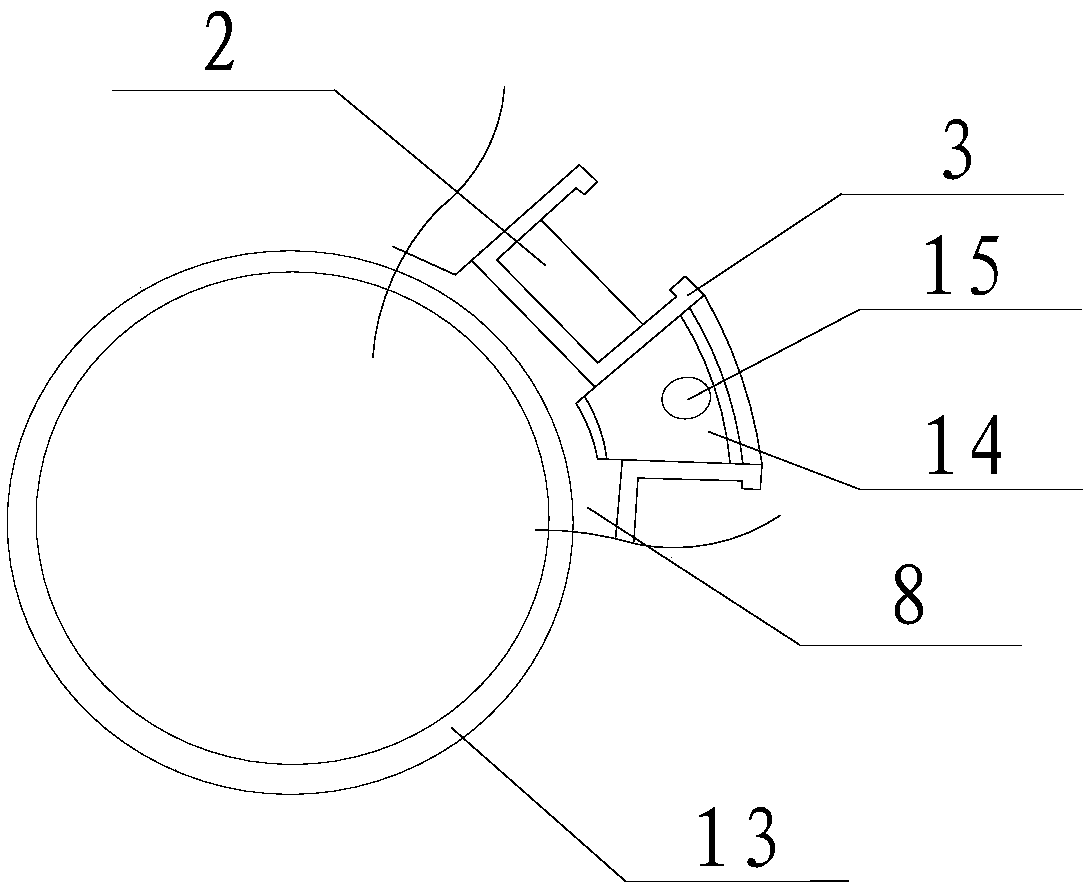

[0026] Wherein, the clamp body 1 mainly includes a fixing part 11, a mounting part 12, a clamping part 13 and a protrusion 14, the mounting part 12 is arranged at the end of the fixing part 11; Hollow cylindrical structure; there are multiple protrusions 14, which are arranged at equal intervals on the peripheral surface of the clamping portion 13, and first fixing holes 15 are embedded in them. The support body 3 is detachably installed between two adjacent protrusions 14. In this embodiment, an accommodating space 31 communicating with the outside is formed in the support body 3, so that the elastic bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com