A prestressed anchor cable and its inner anchor bearing body

A bearing body and inner anchoring technology, which is applied in construction, sheet pile wall, foundation structure engineering, etc., can solve the problem that the inner anchor bearing body is not tightly combined with the surrounding grouting body, and achieves simple structure, uniform and reasonable stress distribution, close-knit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

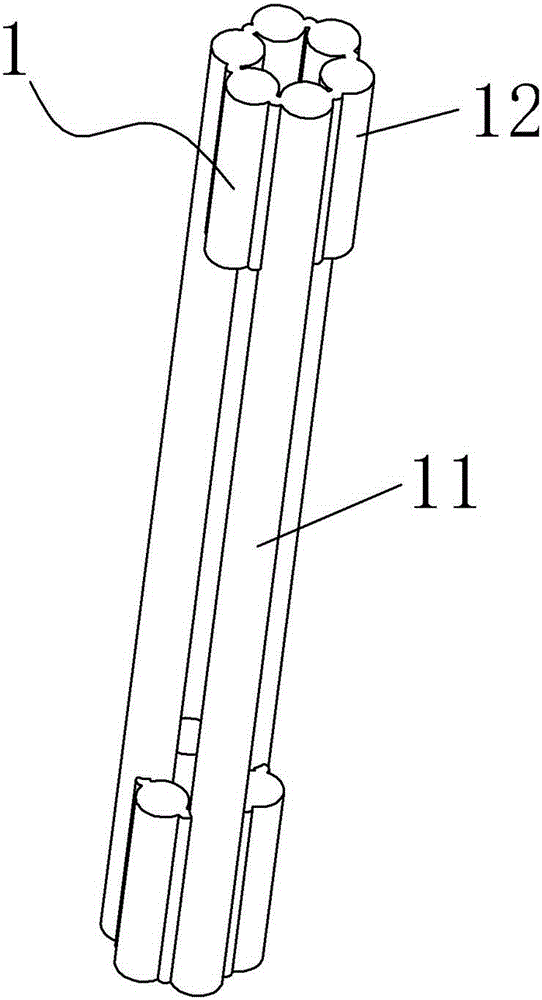

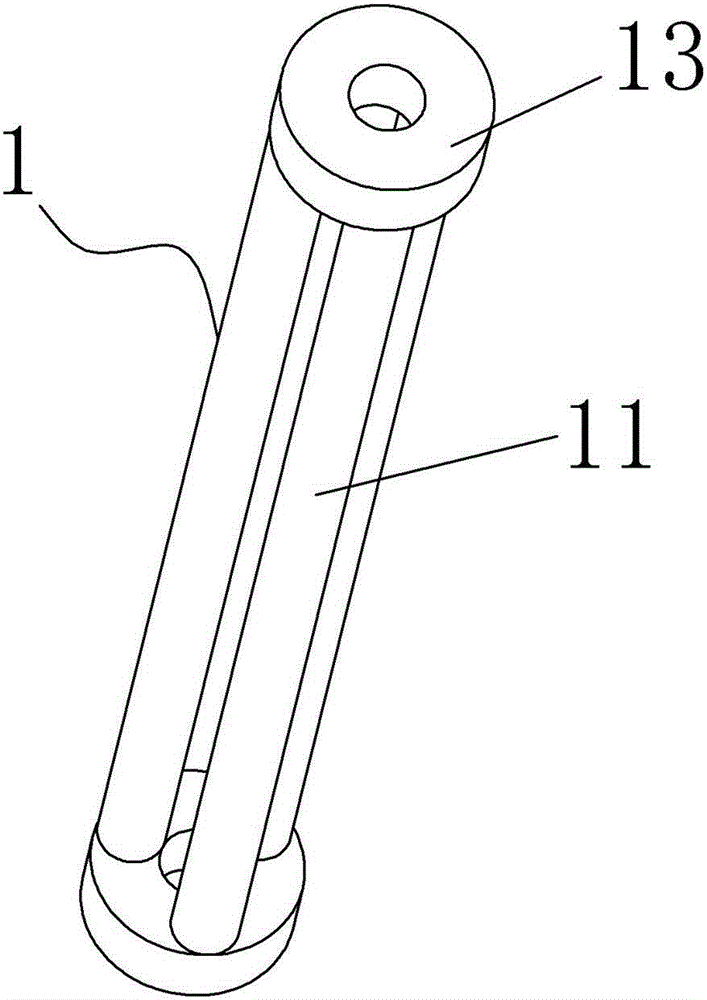

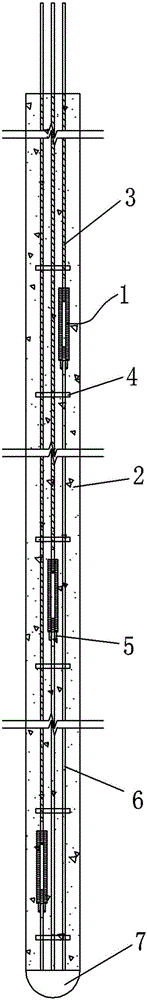

[0028] The first embodiment of the inner anchor carrier in the present invention: as figure 1 As shown, the inner anchor carrier 1 includes a rod body 11, the connecting body that fixes the rod body 11 and makes it spaced is a short rod body 12, the number of the rod body 11 is 3, and the number of the short rod body 12 is 6. Both of them are cut with 18mm diameter steel bars, and then welded and fixed into a cage-shaped cylinder. The diameter of the central through hole of the cage-shaped cylinder is 20mm, which can be used for the steel strands of Φ13, Φ15, and Φ18 commonly used in China. However, the length of the rod body 11 is 400 mm, and the length of the short rod body 12 is 75 mm. The inner anchor bearing body 1 has a wide range of materials and is easy to process. It can be threaded with a steel strand and has a compact structure, which is conducive to lowering and grouting of anchor cables.

[0029] When the inner anchor carrier 1 is used, the outer end surfaces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com