Electric four-way adjusting steering pipe column mechanism and adjusting method thereof

A technology of steering column and steering column, which is applied in the direction of steering mechanism, steering control, transportation and packaging, etc., which can solve the problems of high precision machining of parts, inconvenient operation, and limited holding force of locking mechanism, etc., to achieve improved Safety and reliability, reduced structural complexity, and outstanding adjustment functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

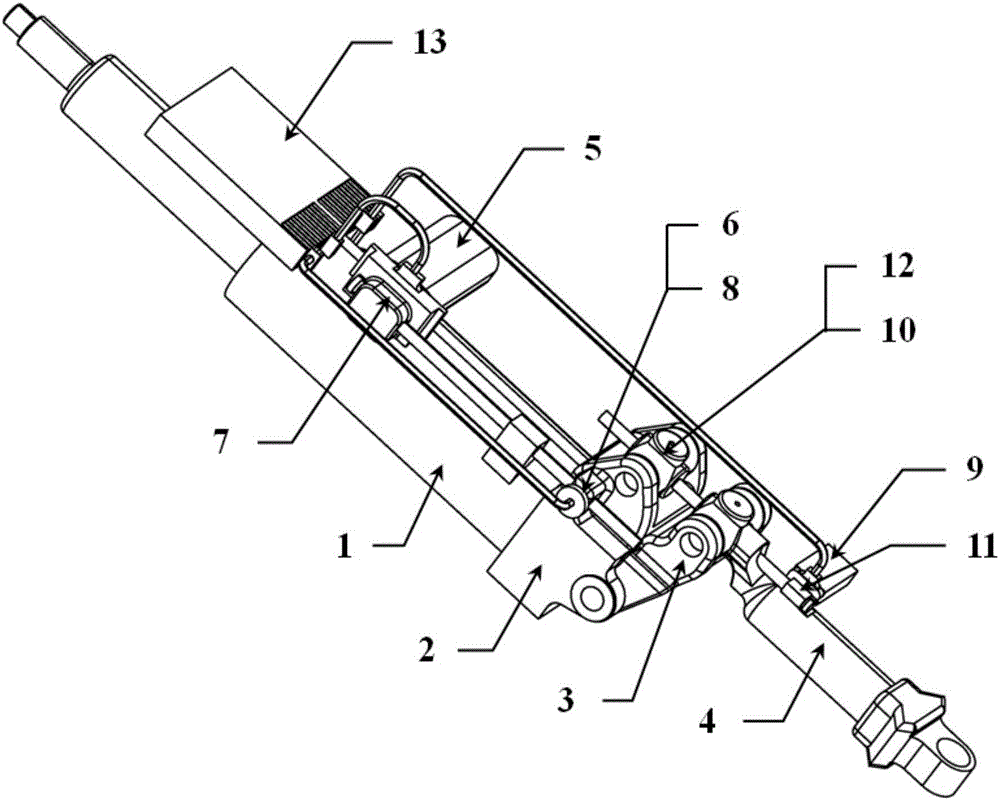

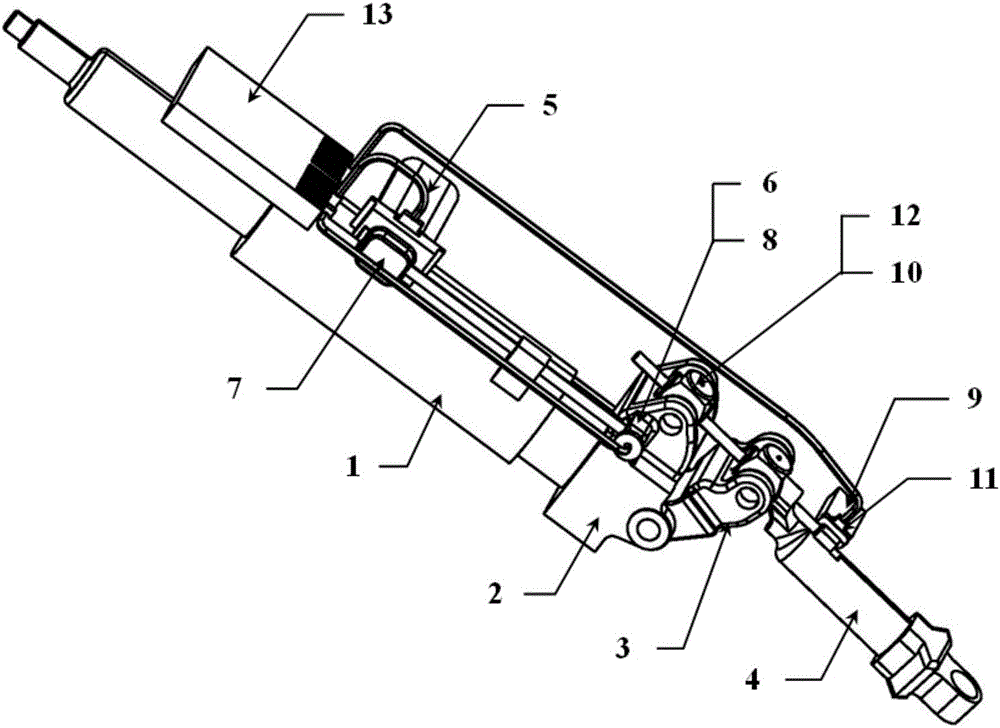

[0021] like figure 1 , 2 As shown, an electric four-way adjustment steering column mechanism includes a column assembly 1, a swing tube assembly 2, a steering column bracket 3, a steering column assembly 4, a displacement motor 5, a displacement sensor 6, and a displacement worm gear reducer. 7. Displacement worm seat 8, angle motor 9, angle sensor 10, angle worm gear reducer 11, angle worm seat 12, controller 13, adjustment button;

[0022] The pipe string assembly 1 is slidably connected with the swing pipe assembly 2 to form a hole-shaft fit, the displacement motor 5 is fixed with the pipe string assembly 1, the displacement worm gear reducer 7 is connected with the displacement motor 5, and the displacement of the displacement worm gear reducer 7 The worm passes through the fixed intermediate support seat on the pipe string assembly 1 and is threadedly connected with the displacement worm seat 8, the displacement sensor 6 is connected with the displacement worm seat 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com