A reinforced structure that penetrates through the front wall panel and the front floor

A technology for strengthening the structure and the front panel, applied in the directions of the superstructure, the sub-assembly of the superstructure, transportation and packaging, etc., can solve the problems such as the deformation and intrusion of the front panel, and improve the anti-collision performance of the car body, and the process is well realized. The effect of maintaining safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

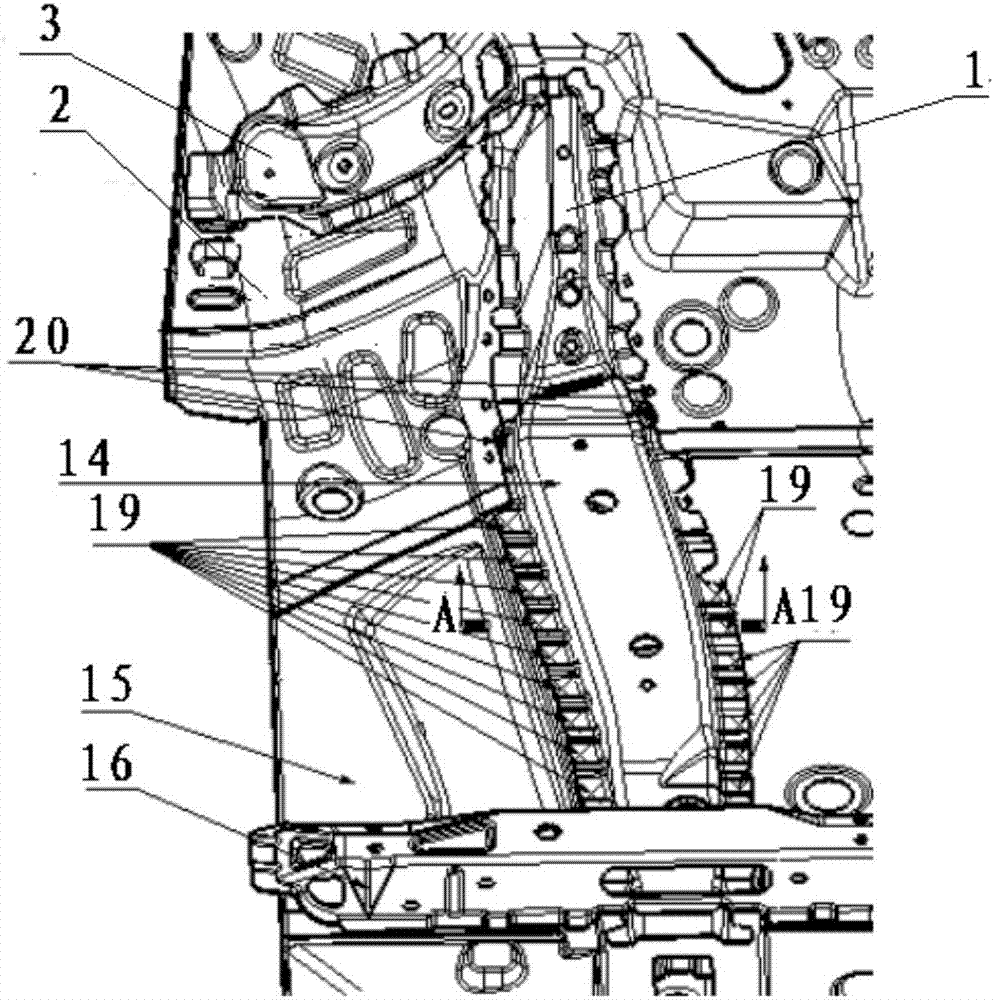

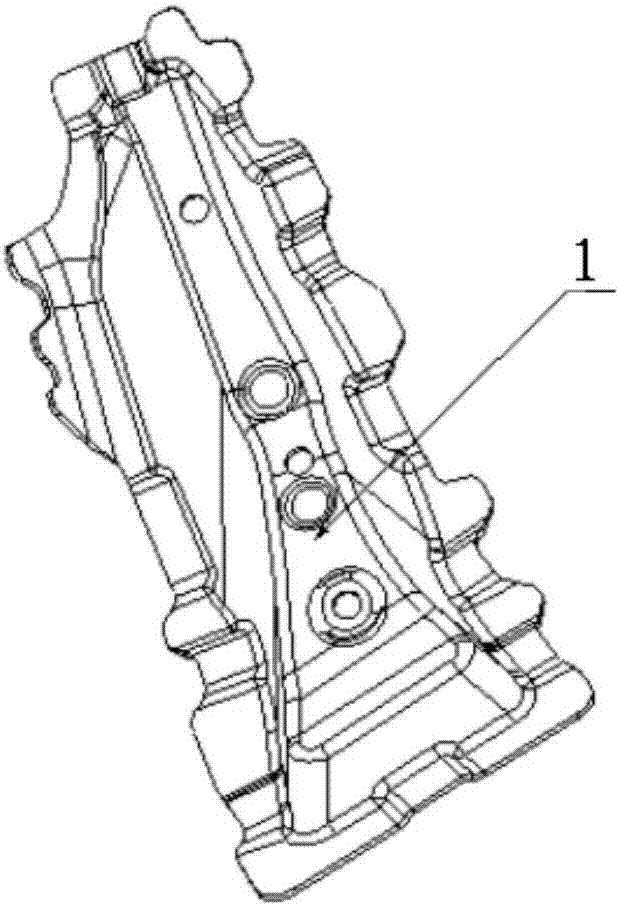

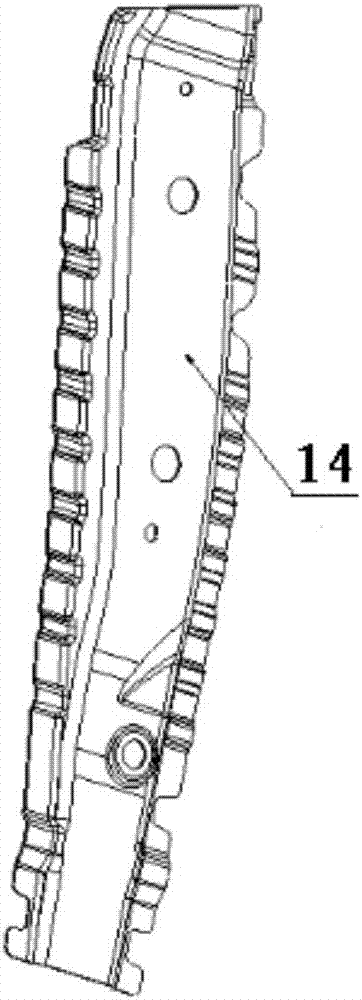

[0021] see Figure 1 to Figure 8 The shown reinforcement structure passing through the front wall panel and the front floor includes a right part and a left part that are arranged symmetrically and have the same structure; the left part includes the left support member 1 of the front wall panel and the left front reinforcement of the front floor connected thereto Part 14, the engine compartment left beam front section 7 adjacent to the left front wall support member 1; also includes a front wall panel connected to the left front wall support member 1 or / and front floor left front reinforcement 14 2. The front floor 15, the left reinforcing beam of the front wall panel 3, the rear section of the left beam of the engine compartment 13, the outer liner 6 of the rear section of the left beam, and the front beam 16 installed on the front row of seats; its features are:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com