Cold drawing film wrapping packaging machine

A packaging machine and film sleeve technology, applied in packaging and other directions, can solve the problems of loose film and easy film loosening, and achieve the effect of small installation space, avoiding film loosening and increasing clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

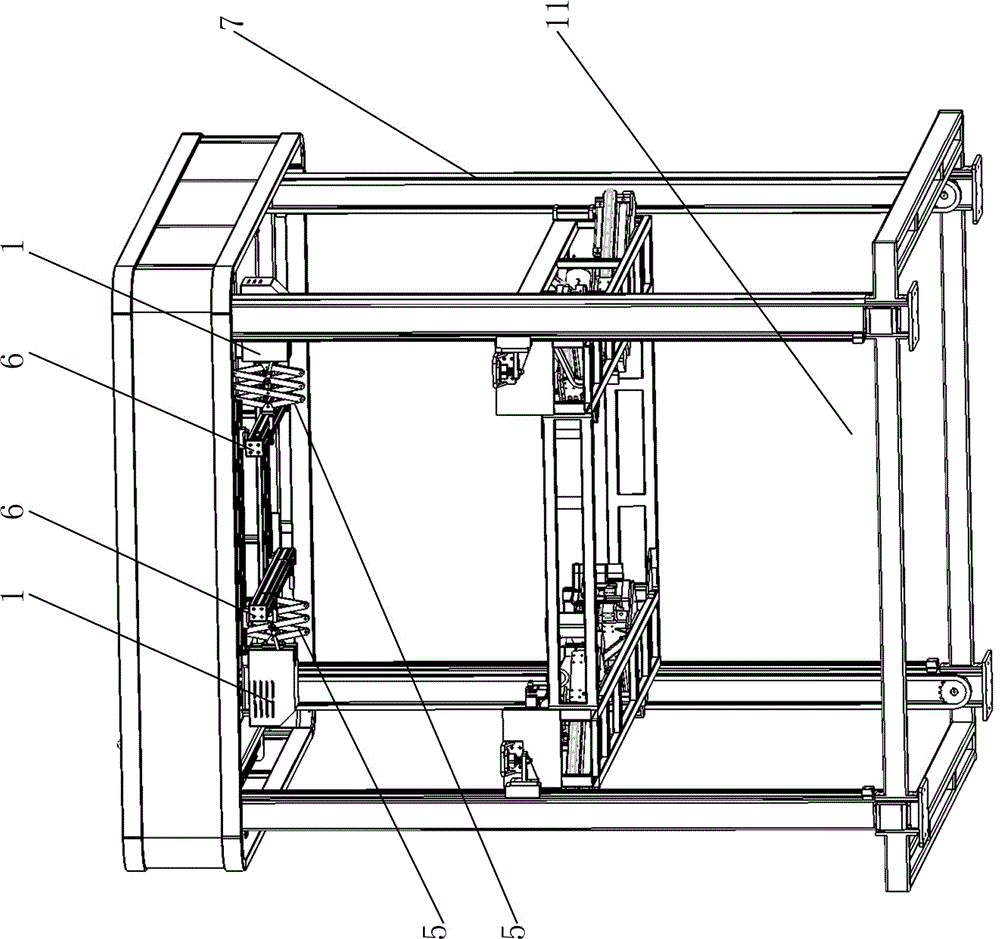

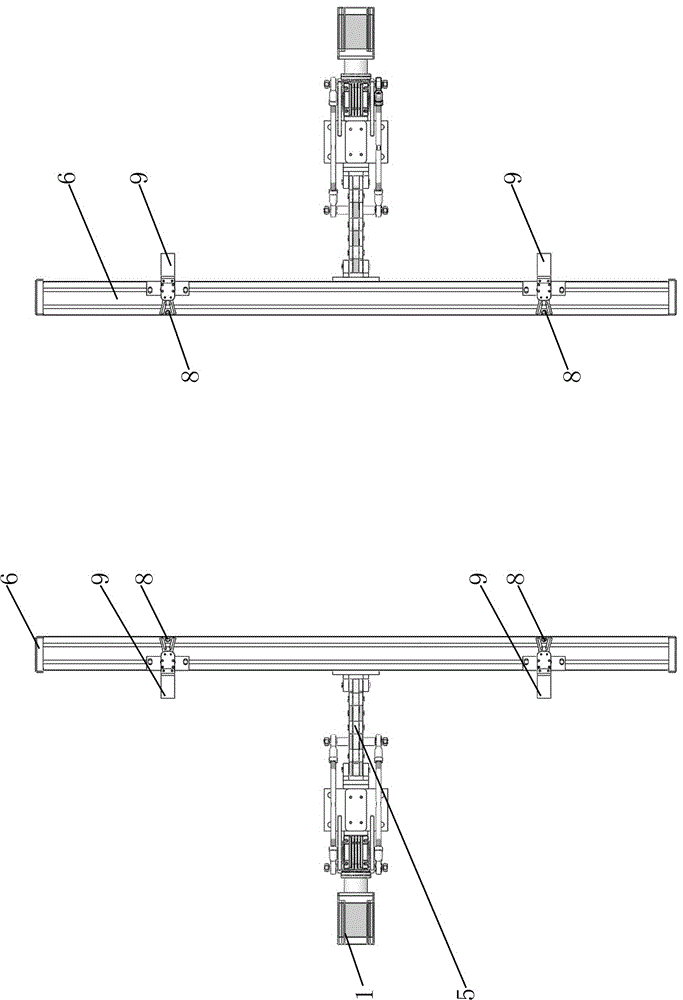

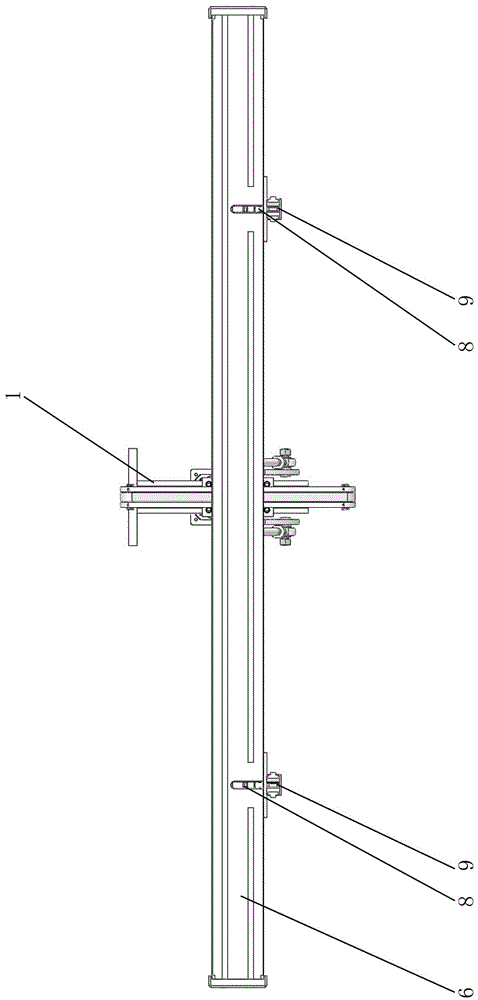

[0025] like Figure 1-5 As shown, the cold stretch hood packaging machine in this embodiment includes a frame 7 and two film suction devices, the two film suction devices are installed on the frame 7 respectively, and the two film suction devices are arranged oppositely .

[0026] The film suction device includes a driving mechanism, a film suction seat 6 and two film suction parts. In this embodiment, the film suction parts are arranged in the film suction seat 6 . The drive mechanism is installed on the frame 7, the film suction seat 6 is connected to the drive mechanism, and the film suction part is provided with an air suction chamber (not visible in the figure) communicated with the external fan, and the front side of the film suction part is opened. Film suction groove 8 is arranged. The film suction groove 8 can suck a part of the film 10 into it, better lock this part of the film 10, making it difficult to leave, just like a person grasps the two places of the film 1...

Embodiment 2

[0039] The difference between the cold stretch hood packaging machine in this embodiment and embodiment 1 is:

[0040] The scissor-type push mechanism is composed of two pairs of short links and a cross link, the right ends of a pair of short links are hinged with the left end of a cross link, and the right end of the cross link is connected with the other pair of short links. Hinged left end.

Embodiment 3

[0042] The difference between the cold stretch hood packaging machine in this embodiment and embodiment 1 is:

[0043] The driving mechanism is an air cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com