Mesh fabric automatic splicer

A veneering machine, fabric technology, used in looms, textiles, textiles, and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

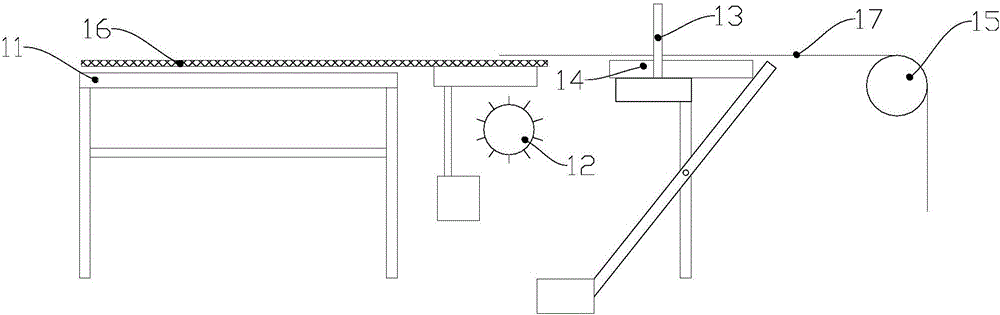

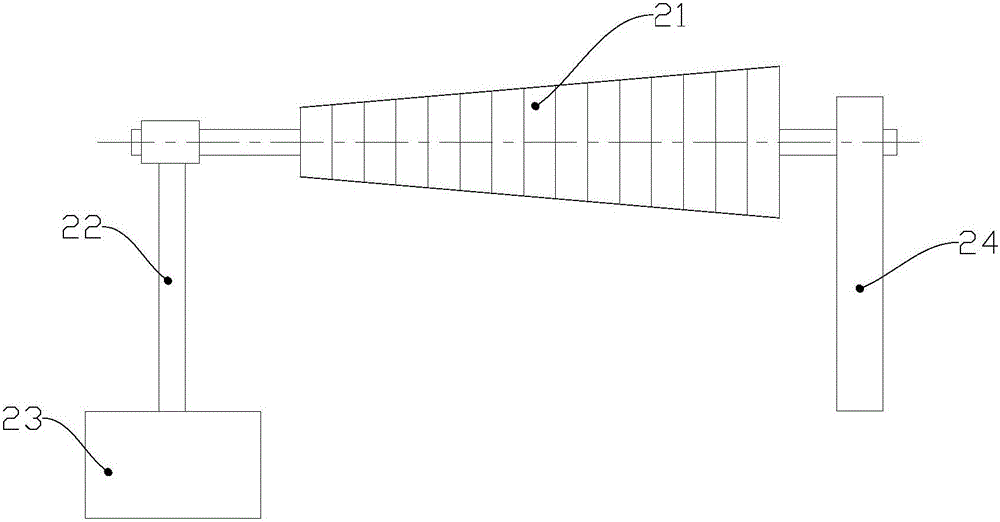

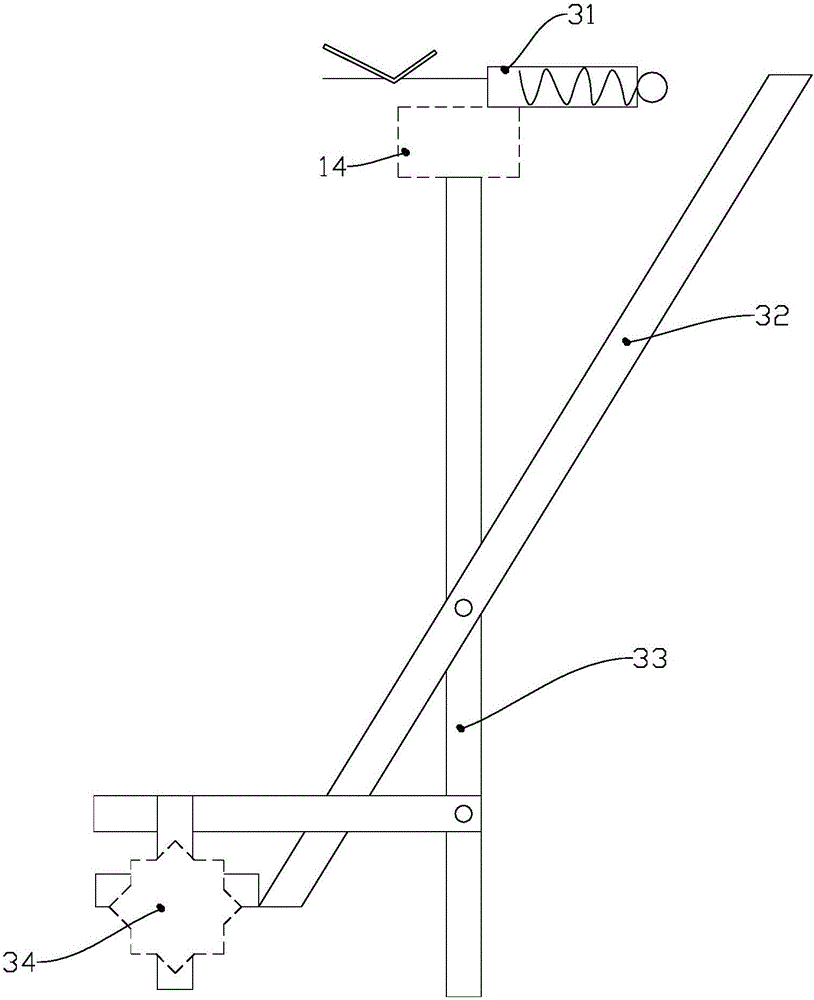

[0016] In order to better understand the present invention, the invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0017] In order to solve the problems existing in the prior art, the present invention provides a device for splicing the bottom wire of papermaking felts and general mesh fabrics, which can realize the seamless connection between multiple pieces of fabrics and realize the connection between the two ends of a single piece of fabric when it is looped. The traceless connection solves the problems that the current production process is completely manual, time-consuming and labor-intensive, and the quality cannot be guaranteed.

[0018] A preferred embodiment of the present invention provides an automatic mesh fabric splicing machine, which splices the original warp (in the length direction) of the mesh fabric to be spliced according to the original fabric structure on the splicing machine. The mesh fab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com